“During my time as an Apprentice Sales Engineer at Thorne and Derrick, I have developed a solid understanding of how our technical products and solutions support customer needs. The apprenticeship has enabled me to expand my knowledge of engineering and sales practices while improving my digital skills, organisation, and communication.

Blog

Stokbord | Protection of HV Cables Up to 33kV In Underground Trenched Applications

November 28th, 2025

Stokbord cable protection covers are rigid HDPE protection boards designed to be installed above buried cables in trenches. They are manufactured and designed by Centriforce to provide strong mechanical protection against impact, backfill pressure and accidental excavation strikes.

The cable covers are available in a range of distinctive colours and feature bold warning text to ensure that they are visible during maintenance and construction projects – optional colours and preferred text sizes are available when placing an order, with personalised text options also possible but dependent on minimum order quantities. Contact T&D for more information.

Not only are Stokbord Cable Covers highly visible and able to withstand large impacts, they are also waterproof and rot proof regardless of acidic or alkaline soil types. Cable covers are fully jointed, laid overlapped and held firm with plastic jointing pegs – a direct replacement for concrete cable covers and steel plate.

Centriforce together with distributor UK Thorne & Derrick Tapetile and Stokbord underground cable protection tiles and covers are the market leading, heavy duty utility protection system for protecting underground cable and pipes – this includes low voltage, medium voltage and high voltage power networks working at 11kV and 33kV.

stokbord cable protection covers

Stokbord covers provide a durable, lightweight protective barrier for buried cables and joint bays, reducing mechanical damage risks and simplifying long-term asset management. This guide walks installers and supervisors through a safe, repeatable workflow for installing Stokbord in a standard utility trench.

How to Install Stokbord Utility Protection in a Trench: A Step-by-Step Guide

Before you start: Materials, tools & checks

Pre-installation checks

- Confirm design drawings and cable routes, depths and separations

- Verify presence and condition of cable bedding and formation

- Check that the correct Stokbord product/spec is available for the voltage and mechanical requirements (Stokbord covers suitable for up to 33 kV where specified)

- Book any required utility isolation or testing with the site electrical team

Step-by-Step Installation

Step 1: Excavate and prepare the trench

- Excavate the trench to the specified depth and width. Keep side slopes stable and safe. Follow excavation safety rules and shoring requirements

- Create a uniform bedding layer to the depth specified (often sand or fine granular material). Remove large stones or debris that could damage cables or covers

- Compact bedding lightly where required, but maintain cable manufacturer’s bedding requirements

Step 2: Lay the cables

- Place cables on the prepared bedding, maintaining the required separation between circuits and other services

- Observe minimum bending radii and cable handling best practice. Use cable rollers or spreaders for long pulls

- Secure temporary supports or spacers where required to keep cables in the correct alignment before placing covers

Step 3: Place Stokbord covers

- Start at one end of the trench. Carefully place the first Stokbord panel so it fully covers the cables in that bay section

- Ensure covers are laid flat and centered over the cable run. Avoid trapping cables between covers maintain clearance and avoid point loads on cable sheaths

- Join adjacent covers using the supplied clips/fixings. Where protection covers need trimming, use the recommended cutting tool and deburr any sharp edges

- For joint bays or irregular sections, use pre-cut pieces or joint bay kits to achieve continuous coverage

Step 4: Secure and seal

- Fit any required edge seals, mechanical fixings, or locking clips per the Stokbord installation guide

- If specified, place geotextile separation layer over covers to prevent stone migration and protect the panel surface

- Lay warning tape (detector tape) at the specified distance above the covers to alert future excavators

Step 5 — Backfill and compact

- Backfill the trench in layers (lifts) with the approved material. Avoid using large clods or stones directly above the panel

- Compact each lift to the specification but avoid over-compaction directly on top of the covers/cables which could cause point loading

- Maintain records of backfill material and compaction trials as required by project QA

Step 6 — Final checks and handover

- Visually inspect the installed protection covers for gaps, poorly joined seams or damage

- Confirm as-built cable positions and panel extents on the site drawings / GPS records

- Provide the client with the installation checklist, any spare covers supplied and recommendations for future maintenance or marker locations

Quality & testing

Common checks:

- Make sure the covers are continuous and joints are fully engaged, small gaps can allow ingress of sharp objects during backfilling

- If covers are damaged during handling, replace the damaged section rather than attempting a field repair unless allowed by the manufacturer

- Ensure warning tape is clearly visible and at the correct depth to aid future excavators

THORNE & DERRICK are national distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, substation earthing, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Restoring Transformer Termination Integrity with LoviSil: A Modern Solution for Ageing PILC Networks

November 28th, 2025

Restoring transformer termination integrity with LoviSil

When a major site recently experienced a fault on an 11kV transformer termination, the challenge was clear: restore the system quickly, safely and without the expense/disruption of full PILC cable replacement.

Upon investigation, engineers discovered that a void had formed within the pitch insulation of the termination box: an all-too-common issue in legacy installations. Although the termination assembly had failed, the underlying PILC cable remained structurally sound and fully capable of continued service.

Instead of replacing the cable, the team opted for a smarter, more efficient approach: upgrade only the insulation system using the proven LoviSil liquid-silicone technology.

Thorne & Derrick are the UK’s specialist distributors for Lovink Enertech: LoviSil, PILC cable jointing solutions and MV termination systems; supporting utilities, DNOs, industrial sites and contractors with market-leading products.

The LoviSil Solution: Upgrading Without Replacing

1. Removing the Old Pitch/Bitumen Medium

All degraded insulation compound was safely extracted from the termination box, exposing a clean cavity ready for refurbishment.

2. Introducing LoviSil Liquid Silicone

The housing was refilled using LoviSil, a premium liquid-silicone medium designed for high-integrity insulation in MV applications.

Performance Advantages of LoviSil

![]()

Enhanced Insulation Performance

LoviSil delivers superior dielectric strength, helping reduce the likelihood of future failure.

Full Void-Free Insulation

The silicone compound flows into every internal space, eliminating air gaps that can lead to partial discharge (PD) and premature breakdown.

Compatible with Legacy PILC Installations

Because the system works seamlessly with the paper insulation of PILC cables, engineers avoided a costly and disruptive network decommissioning.

Long-Term Breakdown Resistance

LoviSil maintains integrity under thermal and electrical stress, offering a modern, robust alternative to historical insulation materials.

Why This Matters for Utilities & Network Operators

This project highlights an increasingly important theme in today’s power networks: extending the life of legacy infrastructure using modern materials and smarter engineering choices.

By retaining the original PILC cable and upgrading only the termination insulation, the client achieved:

-

Significant cost savings

-

Reduced downtime and site disruption

-

Improved long-term network reliability

-

A future-proofed termination assembly

Lovink Enertech products are proven in service worldwide for network resilience, ease of installation, and long-term reliability.

Thorne & Derrick provide expert technical support, fast delivery and comprehensive stock availability for the complete Lovink range from medium voltage straight joints to high voltage transition solutions.

Powering the Solar Revolution: How Klauke Tools are supporting the Solar industry

November 28th, 2025

Powering Solar Installations with Klauke – Now Featuring the EK WF 120 ML

In the fast-growing solar sector, every connection matters. As panel installations scale and systems go to higher currents, installers need tools that combine precision, speed and robustness. At Thorne & Derrick, we’re excited to highlight the Klauke EK WF 120 ML, a powerful addition to our solar tool offering and how it complements the rest of our Klauke range.

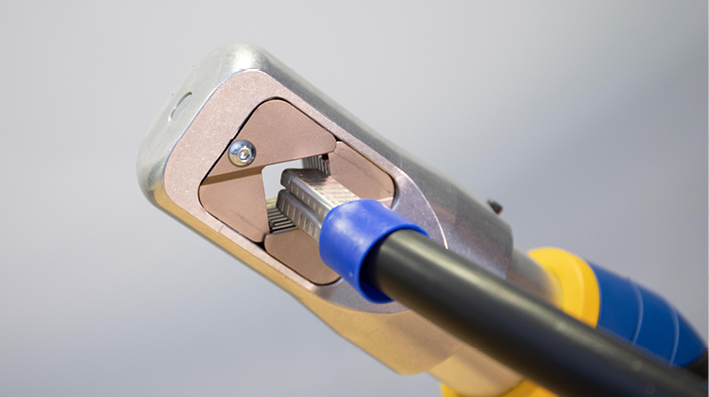

EK WF 120 ML – High-Quality Crimping for Solar Park Installations

When constructing solar parks, including transformer installation – secure, reliable connections are essential. With the battery-powered Klauke EK WF 120 ML Crimping Tool, installers can optimise workflows: faster, easier and with consistently high quality.

Thanks to its innovative square-comb mechanism, the EK WF 120 ML effortlessly crimps DIN-compliant, insulated, twin and insulated twin cable-end sleeves all without needing press inserts. The tool automatically adapts to the cable-end shape, ensuring even force distribution and a perfect crimp every time.

The result is clean, precise crimping across 6–120 mm². For cable end sleeves up to 32 mm in length, one single crimping operation is enough, allowing installers to complete most connections in just one step.

With the EK WF 120 ML, solar installers can rely on maximum efficiency and DIN 46228-compliant quality, helping keep solar park projects smooth, consistent and on schedule.

Klauke EK WF 120 ML

The EK WF 120 ML is a battery-powered hydraulic crimper perfect for larger solar DC conductors.

Key benefits for PV work:

-

Crimps 6–120 mm² with no die changes

-

Square-cam mechanism for consistent, reliable crimps

-

Lightweight + portable for rooftop and field installations

SOME EXTRA Klauke Tools Perfect for Solar InstallATIONS

Battery powered hydraulic cutting tools 32 mm dia.

- The ES32FML is ideally suited for cutting fine and superfine stranded copper cables

- The ES32ML is designed for cutting multi-stranded copper and aluminium cables

- Both tools have a slim cutting head – ideal when space is critical

Battery powered hydraulic cutting tool 50 mm dia. for copper and aluminium cable

- High cutting power for cutting copper and aluminium cables (fine stranded also)

- Saves time with multiple cuts thanks to the manual retract stop (MRS)

- Very low weight (3kg)

- Optimum center of gravity

Battery powered hydraulic crimping tool, 6 – 300 mm²

- The EKM6022 has a very large crimping range of up to 300 mm²

- Interchangeable crimping dies of the 22 series can be used

Electromechanical crimping tool 0,14 – 50 mm²

- With the multitude of available crimping dies, the Klauke micro offers a very wide range of applications

- Excellent crimping results with minimum effort

Battery powered hydraulic crimping tool 10 – 240 mm²

- Extra large crimping area due to innovative 2-stage telescopic cylinder

- Indent crimping – no change of crimping dies required

Why Klauke Tools Make a Difference in Solar

-

Designed for clean, consistent DC terminations

-

Reduce installation time on connectors, strings and terminations

-

Improve long-term reliability of PV systems

-

Safer, repeatable crimping with minimal user effort

Thorne & Derrick

Thorne & Derrick International are UK based and are the leading specialist distributors of LV, MV and HV cable accessories and tooling from 600V to 132kV complemented by an extensive range of hazardous area certified electrical equipment (ATEX and IECEx) to provide compliant, safe and optimised power, heating and lighting. Thorne and Derrick International supports critical infrastructure projects across power, utilities, rail, construction, oil & gas, marine, and process industries. With over 40 years of industry expertise, Thorne & Derrick International delivers trusted products, technical support, and tailored solutions to meet the evolving needs of the energy and industrial process markets.

Thorne & Derrick: Celebrating our Class of 25🎓

November 26th, 2025Meet the Class of 2025

At Thorne & Derrick, we take great pride in developing future talent through our apprenticeship programme. This year, we are delighted to celebrate the success of our Class of 2025 – a group of bright, ambitious individuals who have completed their apprenticeships and are now embarking on the next stage of their professional journeys.

Our apprentices bring energy, innovation, and a fresh perspective to the business. Each has demonstrated resilience, adaptability and a commitment to excellence throughout their training. Together, they represent the future of our industry.

Joseph thane – Business administrator apprentice – level 3

“During my time as a Business Administrator apprentice at Thorne and Derrick, I have developed a strong understanding of how the company operates and supports its customers. The apprenticeship has allowed me to broaden my knowledge of business practices while improving my digital skills, organisation, and professional communication. It has also helped me grow more confident in handling daily tasks, prioritising my workload, and contributing effectively to a busy team environment”

“During my time as a Business Administrator apprentice at Thorne and Derrick, I have developed a strong understanding of how the company operates and supports its customers. The apprenticeship has allowed me to broaden my knowledge of business practices while improving my digital skills, organisation, and professional communication. It has also helped me grow more confident in handling daily tasks, prioritising my workload, and contributing effectively to a busy team environment”

dylan white – apprentice sales engineer – level 4

Harvey andrews – Business administrator apprentice – level 3

“During my time as a Business Administrator apprentice at Thorne and Derrick, I have developed a strong understanding of how the company operates and supports its customers. The apprenticeship has allowed me to broaden my knowledge of business practices while improving my digital skills, organisation, and professional communication. It has also helped me grow more confident in handling daily tasks, prioritising my workload, and contributing effectively to a busy team environment”

CHLOE JOHNSTON – APPRENTICE SALES ENGINEER – LEVEL 4

Millie temple – content creator apprentice – level 3

Thorne & Derrick

Thorne & Derrick International are UK based and are the leading specialist distributors of LV, MV and HV cable accessories and tooling from 600V to 132kV complemented by an extensive range of hazardous area certified electrical equipment (ATEX and IECEx) to provide compliant, safe and optimised power, heating and lighting. Thorne and Derrick International supports critical infrastructure projects across power, utilities, rail, construction, oil & gas, marine, and process industries. With over 40 years of industry expertise, Thorne & Derrick International delivers trusted products, technical support, and tailored solutions to meet the evolving needs of the energy and industrial process markets.

What Is a Transformer Bund Filter?

November 25th, 2025

Transformer Bund Filter

A Complete Guide for Asset Managers

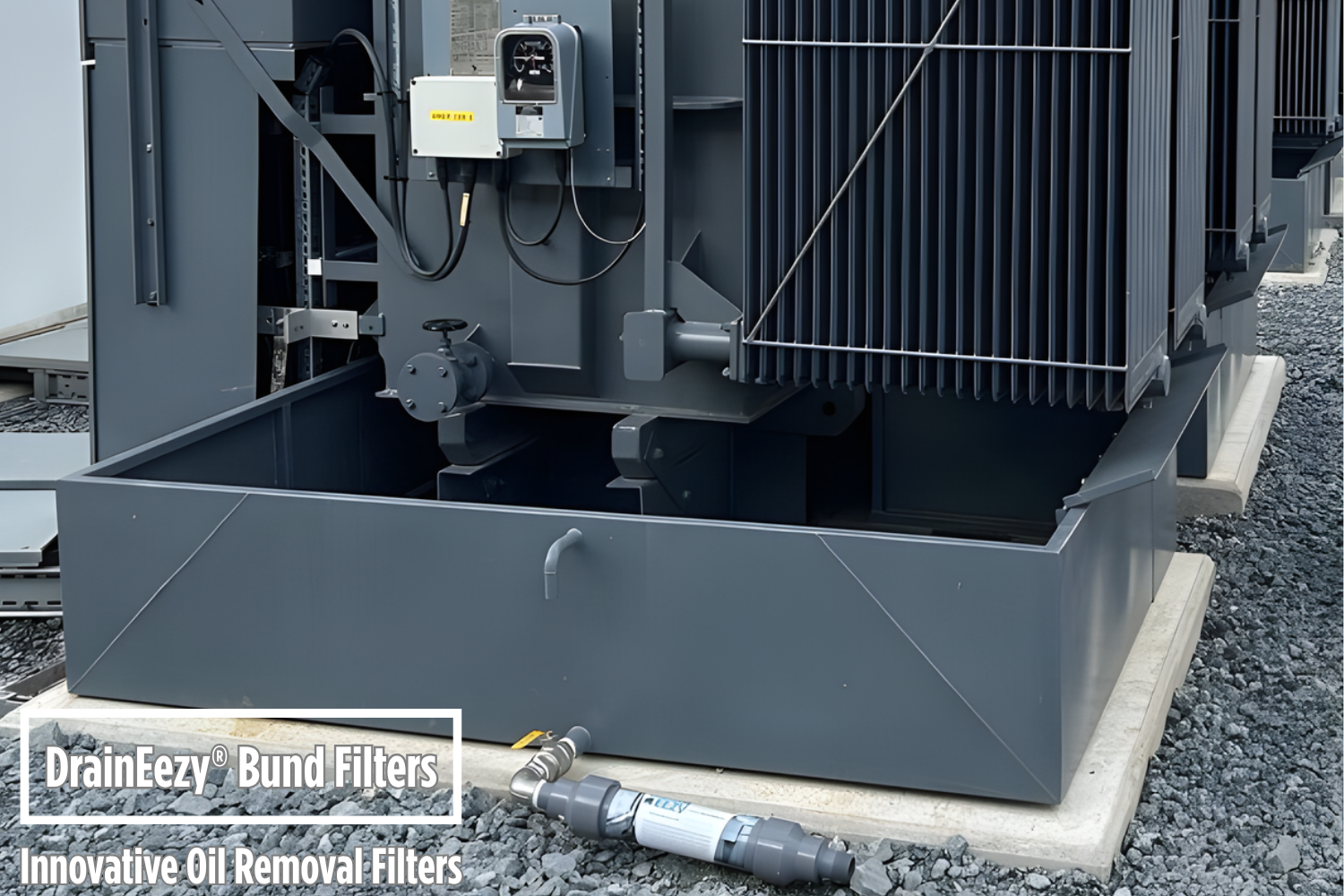

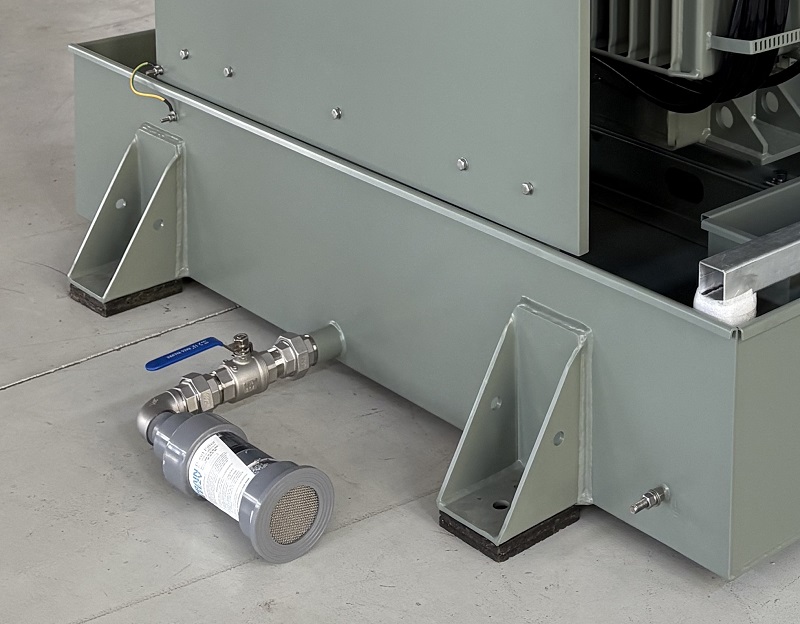

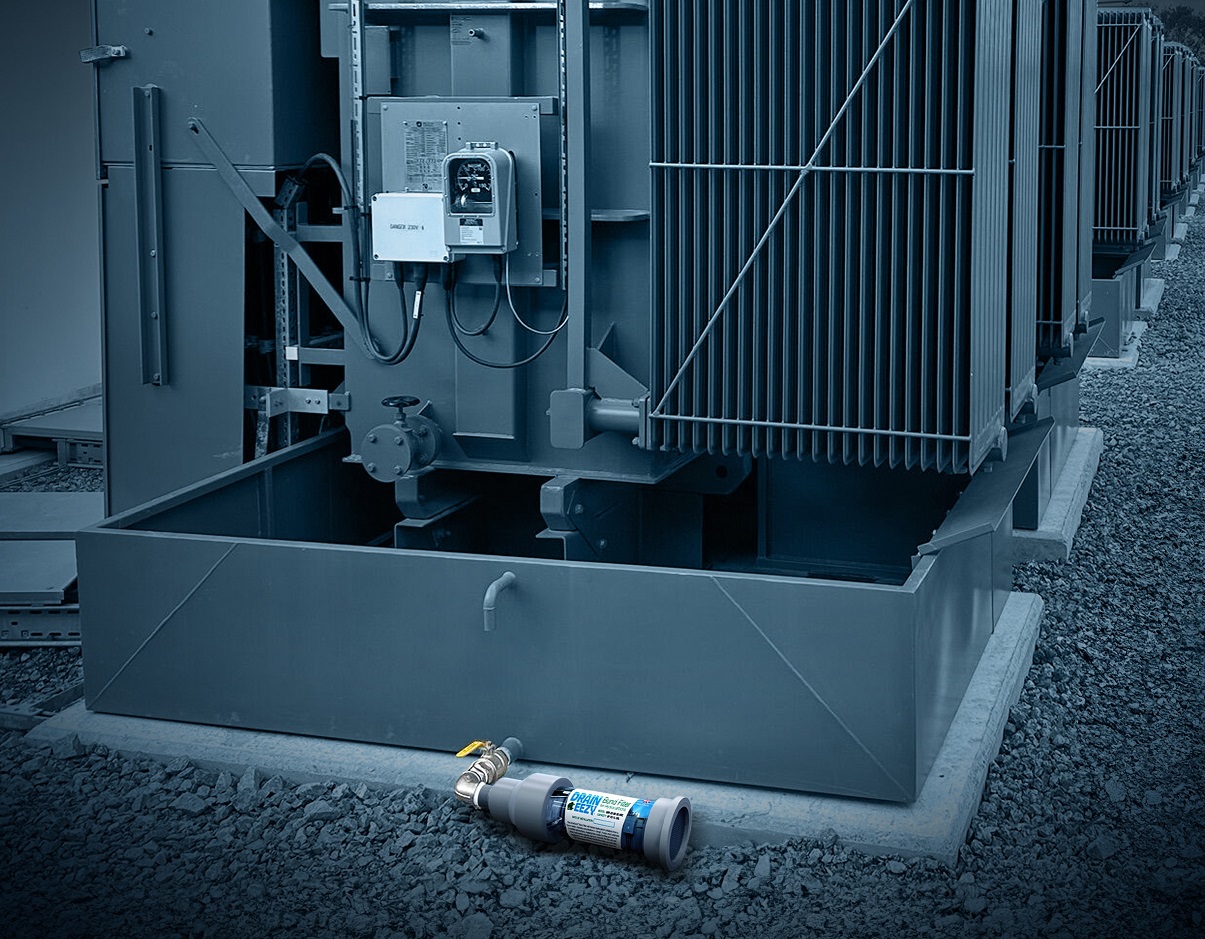

Environmental protection around LV, MV and HV transformers is a growing priority for utilities, renewable energy developers, industrial sites and BESS operators. With increasing regulatory pressure around oil containment, many sites are upgrading to modern Transformer Bund Filters—a passive, low-maintenance system that allows clean rainwater to drain while preventing oil from escaping a transformer bund.

What Is a Transformer Bund Filter?

A Transformer Bund Filter is a passive drainage system installed on oil-filled transformer bunds to let clean rainwater escape while automatically sealing if the filter becomes inundated with oil.. These systems contain hydrocarbon-absorbing media and a self-activating shut-off valve that prevents any contaminated water from leaving the bund.

Why Transformer Bund Filters Are Becoming Industry Standard

DrainEezy Bund Filters are now widely used across:

- Solar farm transformers and inverter skids

- Battery Energy Storage Systems (BESS) sites

- Wind farm transformers

- Data Centre transformers

- Secondary substations

- Industrial transformers

Key Advantages

- Zero power requirement – fully passive filter system

- Automatic oil shut-off – the bund filter seals when inundated with transformer oil

- Low installation costs – quick, easy, field-ready and retro-fittable

- Minimal maintenance – no moving parts

- Ideal for remote sites – extensively installed to steel bunded transformers in the Renewable Energy sectors

How the Draineezy Transformer Bund Filter Works

The DrainEezy system uses hydrophobic media ensuring:

- Allows clean rainwater to pass freely

- Captures hydrocarbons instantly from oil transformer leaks

- Triggers an automatic shut-off valve when inundated with transformer oil

- The filter prevents any oil discharge from the transformer bund

Draineezy BUND FILTERS vs Traditional Oil-Water Separators

| Features | Draineezy Bund Filter | Oil-Water Separator |

|---|---|---|

| Power Required | No | Yes |

| Maintenance | Low | High |

| Installation Cost | Low | High |

| Environmental Risk | Very Low | Medium |

| Response to Oil Spill | Automatic Shut-off | Manual Intervention |

Applications Across Energy & Utilities

- Wind turbine transformer bunds

- Solar farm transformer/inverter bunds

- BESS sites

- DNO/IDNO substations

- Industrial HV transformer bunds

- OEM bund installations

Transformer Bund Filter

Need a Transformer Bund Filter?

Thorne & Derrick supply the full range of Draineezy Transformer Bund Filters, fitting kits, pre-filters and technical support.

|

|

|

| DrainEezy Bund Filter | DrainEezy New Design | Oil Filled Transformers |

LV MV HV Transformers, Cables & Electrical Equipment

Thorne & Derrick distribute the most extensive range of 11kV 33kV Cables, Cable Jointing, Terminating, Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at 11kV 33kV and up to and EHV transmission and distribution voltages; approved stockists and suppliers of 3M Electrical (ColdShrink), Nexans (Euromold), Pfisterer (CONNEX) and Lovink cable accessory and connection products.

Joints, Terminations & Connectors | MV HV | 11kV 33kV 66kV