Blog

Driving Sustainability and Innovation: NEPIC’s Cluster Connect Event 2025

July 2nd, 2025The NEPIC June 2025 Cluster Connect event, hosted at 3M’s Newton Aycliffe facility, was a resounding success, bringing together industry leaders to discuss sustainability, electrical innovation and collaborative growth. Among the highlights were the insightful presentations by Terry McDonald, representing Thorne & Derrick International, and Jenny Swindells from 3M Electrical, who shared their expertise on how the electrical sector is evolving to meet future challenges.

Terry McDonald: A Legacy of Electrical Innovation

Terry McDonald’s presentation delved into the long-standing partnership between Thorne & Derrick and 3M, showcasing how their collaboration has driven advancements in electrical infrastructure, cable jointing, and LV MV HV substation equipment. With decades of experience in the industry, Terry provided a fascinating look into how Thorne & Derrick has been at the forefront of HV and LV electrical solutions, supporting critical projects across the UK and beyond.

Key takeaways from Terry’s talk included:

-

The importance of sustainable electrical solutions in modern infrastructure.

-

How innovation in cable jointing and termination technologies is shaping safer, more efficient power distribution using Cold Shrink technology pioneered by 3M Electrical.

-

The historical journey of Thorne & Derrick and its alignment with 3M’s vision for a greener future.

Attendees left with a deeper appreciation for how industry partnerships can accelerate progress, ensuring that the electrical sector remains resilient and forward-thinking.

Jenny Swindells: 3M’s Commitment to Sustainability

Jenny Swindells, representing 3M, delivered an engaging presentation on sustainability in the electrical sector, emphasising how material science and innovation are paving the way for eco-friendly advancements.

Her discussion highlighted

-

3M’s cutting-edge developments in electrical insulation, Scotchcast Resin, safety products, and renewable energy solutions.

-

The role of circular economy principles in reducing waste and improving efficiency.

-

How collaboration between companies like 3M and Thorne & Derrick fosters industry-wide progress.

The site tour of 3M’s Newton Aycliffe facility further reinforced these insights, giving attendees a first-hand look at the ground-breaking work being done behind the scenes.

A Morning of Networking and Inspiration

The event was a fantastic opportunity for professionals across the Northeast Process Industry Cluster (NEPIC) to connect, share ideas, and explore future collaborations. The combination of expert insights, facility tours, and networking made it a truly enriching experience.

A huge thank you to 3M hosting such an inspiring event. The discussions on sustainability, innovation, and partnership have set the stage for even greater advancements in the electrical sector.

About Thorne and Derrick International

Thorne & Derrick International are UK based and are the leading specialist distributors of LV, MV and HV cable accessories, joints, terminations and tooling from 600V to 132kV complemented by an extensive range of hazardous area certified electrical equipment (ATEX and IECEx) to provide compliant, safe and optimised power, heating and lighting.

Thorne and Derrick International supports critical infrastructure projects across power, utilities, rail, construction, oil & gas, marine, and process industries.

With over 40 years of industry expertise, Thorne & Derrick International delivers trusted products, technical support, and tailored solutions to meet the evolving needs of the energy and industrial process markets.

Thick Cable Sheath Removal in Tight Spaces with the Ripley US15 PRO MAX

June 25th, 2025How Good Is The Ripley US15 PRO MAX?

A must have for your cable jointing tool box, the Ripley US15 PRO MAX is the perfect solution for precise safe cable outer sheath jacket removal from LV MV HV power cables. Whether the cable is thin or thick, the US15 PRO MAX performs fully adjustable cuts on cable diameters from 38mm to 80mm, whilst maintaining the underlying layers of the cable.

The professional heavy-duty cable sheath jacket stripping tool can cut through many types of insulated material, including PE, XLPE, PVC, EPR, EPDM, TGGT, Silicone Rubber and Sealpic, creating clean ring, spiral and longitudinal cuts. Ultimately, the Ripley US15 eliminates the need for basic cable cutting tools, improving safety, preventing possible cable damage, and delivering reliable results.

- Flexible and adjustable blade position and cutting depth

- Suitable for hard and soft insulated power cables with diameter of 38mm – 80mm

- Compatible with a number of varied insulated materials

How do I remove the cable outer sheath after cutting? The Ripley US15-7020 Cable Sheath & Jacket Lifting Tool is the safest solution for lifting a jacket from a LV MV HV power cable, rather than using a standard knife.

Thick Cable sHEATH rEMOVAL, Close Quarters, No Problem!

The Ripley US15 PRO MAX made this job effortless. Challenged with an incredibly thick cable outer sheath jacket (around 65mm diameter) in a small space, Harvey selected the US15 PRO MAX to solve the limited flexibility hurdle.

Starting with a circumferential cut, then seamlessly switching to a spiral cut and pushing up to create a quick, easy and effective slice. Due to the power cable being in an awkward position and thick insulation, the cable was difficult to bend. Using the Ripley US15 PRO MAX was the ideal tool to spiral the cable and manoeuvre the debris. In this case, Harvey used a standard knife to pop and unwrap the cable outer sheath jacket from the cable.

RIPLEY Tools

Experts in Cable Jointing Tool Design

Founded in 1936, Ripley are market-leaders in manufacturing equipment, tools and technology for specialised applications. Offering a pioneering approach to product design, has enabled Ripley to create innovative tools that solve the everyday challenges faced by linemen, cable engineers, technicians and installers. Including complete ranges of FO LV MV HV cable preparation tools, designed to enable the stripping and removal of cable sheath/jacket, and LV MV HV cable jointing tools, purposed for the jointing of LV HV HV power cables.

As well as the Ripley US15 PRO MAX, Thorne & Derrick are also stockists and suppliers of the complete Ripley Tools range, including Ripley US15-7000 (10mm to 60mm cable diameter) and Ripley US15-7010 PRO (10mm to 60mm cable diameter) Cable Sheath Jacket Stripping Tools. We offer competitive pricing, excellent customer service and fast worldwide delivery, for a seamless buying experience.

Contact our experts and discuss your cable tooling requirements.

Evolution from Local Distributor to Trusted International Partner for High Voltage, Process & Hazardous Area Solutions – Thorne & Derrick Celebrates Local to Global over 40 Years

June 13th, 2025

Thorne & Derrick Celebrates Local to Global over 40 Years

Thorne & Derrick International, a leading distributor of power systems, hazardous area equipment, and process heating solutions, is proud to celebrate its 40th anniversary this year.

Established in 1985 by Victor Thorne and Brian Derrick, the business started trading as Thorne & Derrick from premises in Brislington, Bristol. From the outset, the Company built a strong reputation, representing world-renowned manufacturers such as 3M Electrical, Band-It, and Cembre, supplying their market leading products to critical infrastructure projects and industries.

In 1988 expansion came with the acquisition of Reid Brothers (Glasgow), strengthening the Company’s presence in the strapping and load securing market.

A major milestone came in 1992, when Richard Derrick began operating in the Northeast of England working from a home office in Fenham, Newcastle. Initially Richard focused on selling Electrical Trace Heating solutions from Raychem, but after a move to Gear House in Gateshead, the Northern business expanded into the LV and HV power market. After 23 years, the office relocated to the current Northern headquarters at Lumley Court, Chester-le-Street which is the engine room of the company’s sales and marketing activity today.

In 2015, Reid Brothers was purchased from Thorne & Derrick International, in a management team buyout and is still thriving today.

Meanwhile, after 31 years in Brislington, Bristol, significant business growth forced a relocation in 2016 to Whitchurch, Bristol, where it continues to operate as the Company’s central warehouse and administration centre, coupled with a very strong Export and UK sales department.

Over four decades, Thorne & Derrick International has grown from its initial team of 6 to over 30 staff and from a first order of just £500 in August 1985, the Company is now on track to deliver over £20 million turnover in the very near future.

From the 1980s onwards, the Company has played an important role in serving the Oil & Gas, Process and Petrochemical sectors, and that has been central to its growth. As these markets continues to change, the business has expanded its product range in support, ensuring continued relevance and service excellence.

“As Managing Director, I’m incredibly proud of the team we’ve built over the years. Our strong focus on investing in young talent through apprenticeships has not only helped shape skilled professionals, but has also fostered a culture of loyalty and dedication,” said Richard Derrick. “It’s rewarding to see so many of our people grow with the Company. Their expertise and commitment are at the heart of our continued success.”

The team of technical sales engineers, sourcing specialists and customer service advisors, deliver a single-source logistics solutions across the UK and internationally, supporting projects in more than 120 countries across five continents, offering rapid delivery and tailored supply strategies.

With global electricity demand predicted to more than double by 2050, Thorne and Derrick International are strengthening and extending their world class supply chain to support grid-scale projects to drive our sustainable energy future towards net zero through renewable energy, digitalisation and decarbonisation of industry.

Thorne & Derrick International are the UK’s leading distributors of High Voltage Power Cable Accessories and Hazardous Area Electrical supporting critical infrastructure across power, utilities, rail, construction, oil & gas, petrochemical and process sectors. With over 40 years of industry expertise, Thorne & Derrick International delivers trusted products, technical support, and tailored solutions to meet the evolving needs of the energy and industrial markets.

About Thorne and Derrick International

Thorne & Derrick International are UK based and are the leading specialist distributors of LV, MV and HV cable accessories and tooling from 600V to 132kV complemented by an extensive range of hazardous area certified electrical equipment (ATEX and IECEx) to provide compliant, safe and optimised power, heating and lighting. Thorne and Derrick International supports critical infrastructure projects across power, utilities, rail, construction, oil & gas, marine, and process industries. With over 40 years of industry expertise, Thorne & Derrick International delivers trusted products, technical support, and tailored solutions to meet the evolving needs of the energy and industrial process markets.

Dropped Objects & How To Prevent Them

June 10th, 2025 Prevent Dropped Objects

Prevent Dropped Objects

To prevent dropped objects it is recommended to implement a multifaceted approach that includes physical barriers, tool tethering, proper storage, training and regular inspections. This strategy aims to minimize the risk of objects falling from height and causing harm or damage – we welcome your Enquiries for workplace products that prevent dropped objects and mitigate risk to plant and personnel.

-

Toeboards & Handrails

Ensure these are securely fixed on scaffolding, platforms and walkways to prevent objects from falling through gaps.

-

Netting

Utilize safety mesh or rated barrier netting in areas where objects might fall, especially around walkways, platforms, and building perimeters.

-

Catch Platforms

Consider using temporary roofing, floor fabrics, or other means to shield workers below from falling objects.

Dropped Object Prevention | Netting is used to enclose objects at height to prevent them posing a dropped object risk.

-

Tool Lanyards & Tethers

Secure tools and equipment using lanyards, tethers, pouches, holsters, and other drop containment devices.

-

Proper Storage

When not in use, tools and materials should be properly stored and secured.

-

Avoid Hanging Over Railings

Never hang or drape items over guardrails, as this can cause them to fall.

-

Keep Tools and Materials Away from Edges

Maintain a safe distance (at least 3 feet) from any leading edges when tools and materials are not in use.

-

Education on Risks

Train workers on the dangers of dropped objects and how to minimize the risk.

-

Hazard Hunts

Conduct regular inspections and periodic “hazard hunts” to identify potential hazards.

-

Housekeeping

Maintain high housekeeping standards to reduce the risk of loose objects falling.

-

Regular InspectionsImplement a risk-based inspection plan to identify and address potential dropped object hazards.

-

Inspection of EquipmentInspect equipment that is in continual use or difficult to access, especially after major stresses like adverse weather or collisions.

-

Corrective Action

Document any nonconformities, assess their criticality, and implement corrective actions.

-

Lowering Working Platforms

When possible, lower the working platform to ground level and lift the structure into position rather than taking tools and equipment to height.

-

Using Mechanized Means

Utilize pulley systems, ropes, or tool bags and belts to move tools and materials, reducing hand-carrying.

-

PPE

Ensure workers wear appropriate personal protective equipment (clothing and PPE), including hard hats and climbing helmets.

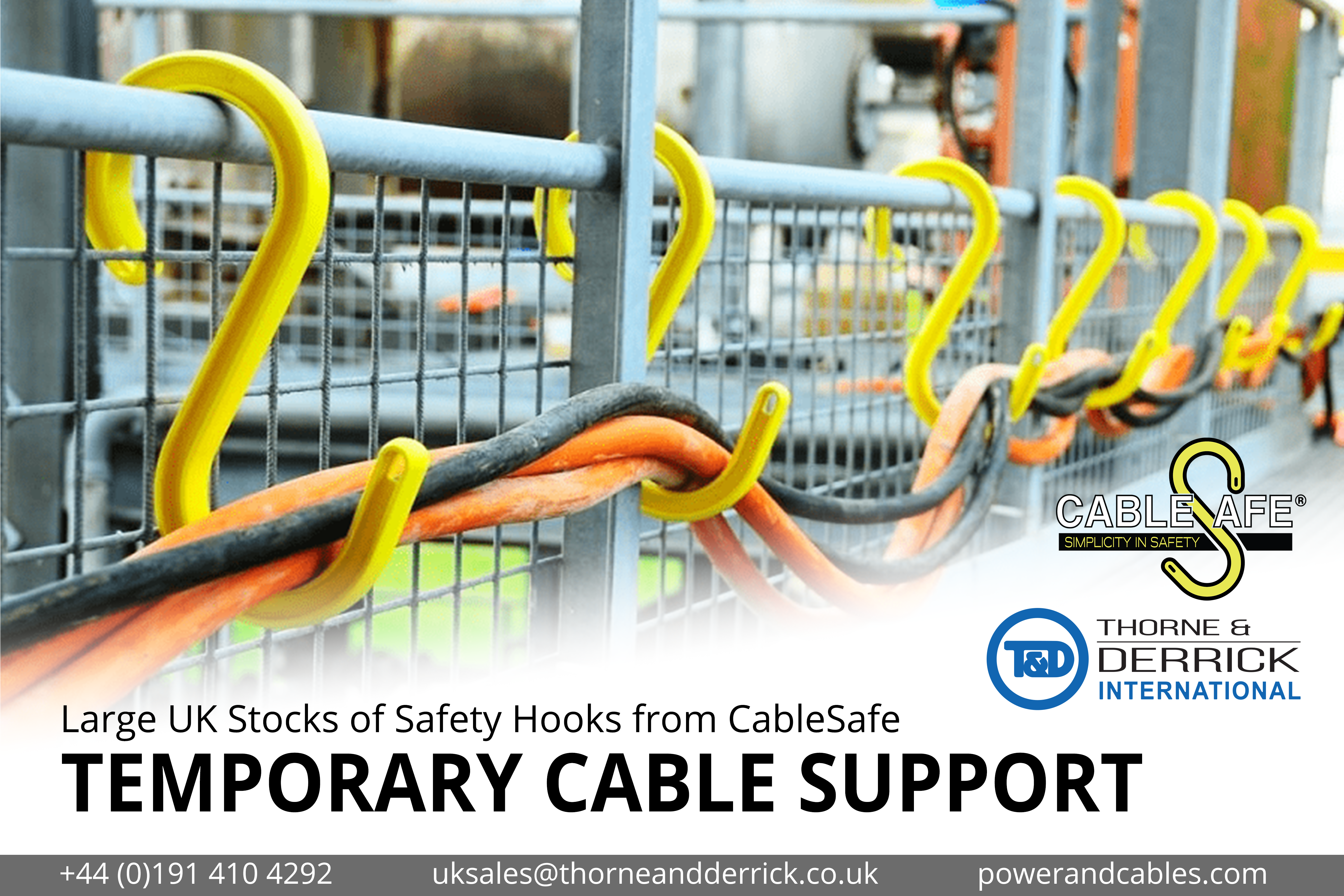

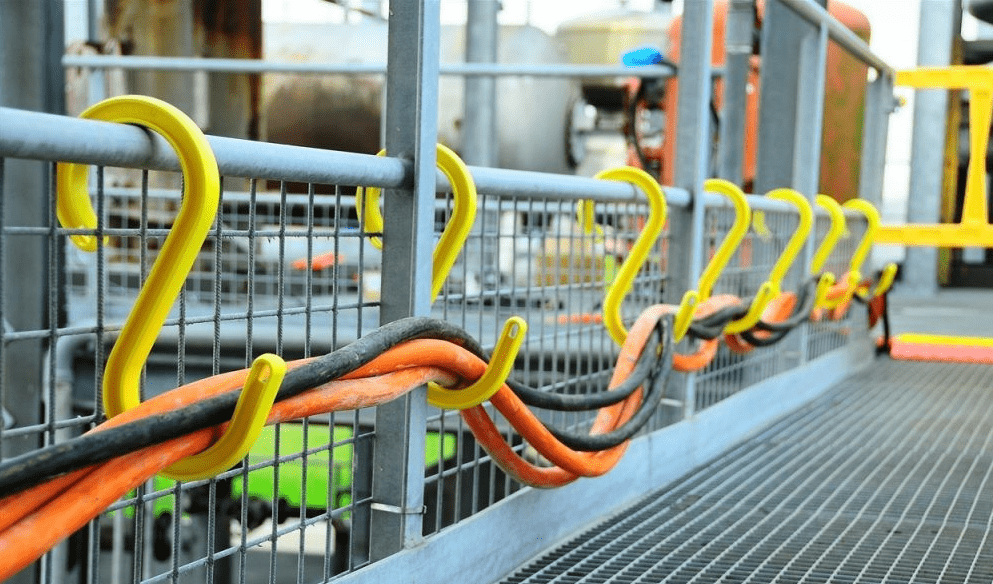

Cable Hooks | Reduce Slips, Trips & Falls from Trailing Cables

May 30th, 2025The Future of Cable Management – Trends & Innovations

-

uploaded by Chris Dodds (Thorne & Derrick) with accreditation to CableSafe.

In the engineering landscape, staying ahead of things is crucial, especially when it comes to cable management. At CableSafe, with operations spanning the Netherlands and the USA, we’re dedicated to pioneering innovative solutions in cable safety, confined space safety, and dropped objects prevention. Let’s delve into the future of cable management, examining emerging trends and exciting innovations shaping the industry.

Efficient cable organization is essential for optimizing workflows and minimizing hazards in industrial settings. Traditional methods often involve cumbersome cable trays and racks, but advancements in cable management solutions are simplifying the process. Products like CableSafe Safety Hooks Extreme and Cable Guards provide simple yet effective solutions for keeping cables organized and secure, reducing clutter and potential safety risks.

Elevated cable management solutions like CableSafe Cable Stands and Cable Bridge further streamline operations by minimizing tripping hazards and facilitating easier access for maintenance personnel. These innovations not only improve electrical safety but also contribute to overall efficiency on the job site.

As technology continues to advance, ensuring cable safety remains a top priority. CableSafe is dedicated to developing robust cable protection systems that mitigate risks and prevent accidents. Whether it’s through innovative cable guards or durable safety hooks, our products are designed to withstand the rigors of industrial environments while keeping workers safe.

Trailing Cable Safety

The Safety Hook Extreme is an advanced specification and high performance version of the standard industrial cable hook manufactured with glass reinforced PBT and is UV stabilized, Flame Retardant (Class: 94V-0, Flame Class Rating 3) and Cold Weather rated.

CableSafe Hooks

Looking ahead, the future of cable safety lies in proactive prevention measures and advanced monitoring technologies. By investing in smart solutions that detect potential hazards before they escalate, companies can minimize downtime and maximize productivity while safeguarding their workforce.

Every industry has its own unique challenges when it comes to cable management. From offshore oil rigs, wind turbines and to manufacturing facilities, CableSafe understands the importance of tailored solutions for elevating trailing cables. Our customizable products are designed to meet the specific needs of diverse industries, from corrosion-resistant materials for marine applications to fire-retardant coatings for high-risk environments.

As we look to the future, CableSafe remains committed to driving innovation and excellence in temporary, permanent and trailing cable management. By embracing emerging trends and leveraging cutting-edge technologies, we’re shaping the industry for the better. With our customizable solutions and unwavering dedication to safety, we’re empowering companies to create safer, more efficient workplaces for their employees.

Should you require any further information about improving Electrical & Cable Safety in your workplace, contact Thorne & Derrick.

Further Reading