Cable Strikes

Cable Strikes | HV Cable Joint Explosion

May 18th, 2021

Cable Strikes

Utility Strike Avoidance Group

USAG have published a range of documents to assist industry understanding of the root cause and contributory factors behind specific incidents. The aim is to improve industry standards and reduce the number of cable strikes.

Cable damage is often caused by excavating machines – hand held tools such as pneumatic drills, crowbars, pins, picks and forks also expose workers to potential sources of danger when digging around underground cables.

Cable Hangers | Cable Ducting | Cable Protection | Electrical Safety Equipment

Incident Overview

What Happened?

A trial hole was excavated at a site in Wisbech, it was left open whilst other works on the site continued. Late in the evening an old clay cable joint surrounding an exposed steel wire armoured high voltage cable (11kV) exploded. The explosion set fire to roadside barriers that were lying over the hand excavated trial hole.

On the days prior to the joint failing it had rained but the excavation had not filled with water. The condition of the exposed cable and joint was believed to be in good condition when initially exposed.

The Fire Service and Police arrived on site, extinguished the fire and made the area safe. The loss of power affected approximately 1600 properties; thankfully no-one was injured.

What Do You Need To Do?

- Whenever you uncover a low or high voltage clay joint, or any type of cable joint which appears to be damaged or in poor condition, contact the local utility owner to inspect the joint before work continues in the immediate vicinity.

- Always support cables and joints in excavations appropriately, they must be suitable supported to prevent sag and strain on the joint.

- Never use other utilities to access and egress to and from excavations.

- Where possible use pumps to avoid excavations filling with water and submerging joints.

- Use appropriate security measures to keep members of the public safe.

Protecting Cables Against Strikes & Restoring Power Post-Strike

Thorne & Derrick have been distributors for 3M Electrical since 1985 and can provide a range of reliable and easy to install Cable Repair Products – this includes Scotch Tapes, Scotchcast Joints and Cold Shrink Tubes to provide effective re-instatement of cable sheath jackets on all types of LV MV HV cables in onshore and offshore locations with safe or hazardous area workplace classifications.

Cable Repair Products

Our range of cable protection covers manufactured by Centriforce provide underground utility protection of LV MV HV cables including Tapetile (11kV) and Stokbord (33kV 66kV 132kV) – contact us to discuss Cable Damage Prevention Products including Dectamesh, the underground detectable warning tape for alerting excavators of the presence of buried cables and to prevent potentially lethal accidents during excavation.

Cable Strikes | Gas and Electric Service Strikes

May 11th, 2021

Cable Strikes

Utility Strike Avoidance Group

USAG have published a range of documents to assist industry understanding of the root cause and contributory factors behind specific incidents. The aim is to improve industry standards and reduce the number of cable strikes.

Cable damage is usually caused by excavating machines – hand held tools such as pneumatic drills, crowbars, pins, picks and forks also expose workers to potential sources of danger when digging around underground cables.

The next in the series is a safety alert thanks to Highway England regarding a series of cable strikes to a 20mm gas pipe and a low-voltage electric cable.

Series of Service Strikes

Background to the Incident

In May of 2020, a 20mm gas pipe and a low-voltage electric cable were struck in Wardington and on the M40 J11 improvement works respectively.

In August 2020, another low-voltage electric cable was struck on the M40 J11 improvement works. Investigations into these incidents revealed that all Fusion processes were followed:

- Prior to works being undertaken, utility drawings were made available.

- PAS 128 survey of the area was undertaken including the Ground Penetrating Radar (GPR) and Electro-Magnetic Locating (EML) surveys.

- A permit to dig was issued and the gang was briefed on the work to be carried out.

- The gangs were experienced and deemed competent.

- Works were supervised and service locators were on-site.

- All hand tools were insulated.

- All services were shallow (< 300mm).

Considerations

Utility drawings can be inaccurate and out of date, and so alone are not to be relied on.

Utilities should be installed as per industry standards, which include depths of over 450mm with proximity warning aids including coloured tape to identify utility types and surrounding the service in a bed of peashingle – none of these services struck complied.

Key Findings and Action Taken to Prevent Reoccurrence

- The Junction 11 package of works obtained their PAS 128 data for their permit to break ground system from an external source rather than from the established Fusion PAS 128 team. It was not mandated by Fusion to have to use this team. It has now been mandated that all PAS 128 surveys required for Fusion sites, will now be managed by the Fusion PAS 128 team and follow the same stringent analysis and assurance process.

- Further investigation of the PAS 128 data – i.e. interpretation of utility drawings and other information available when on site conducting the Electro-Magnetic Location (EML – CAT&Genny) surveys, showed the external supplier interpreted the information differently to the Fusion PAS 128 team. Although people with the appropriate training are deemed competent, it should be recognised that those with more experience are more likely to interpret information with a higher degree of accuracy.

- The absence of street furniture and other equipment is not a reliable indication of a lack of underground cables and caution must be exercised at all times whilst breaking ground and digging.

➡ Thorne & Derrick distributes Insulated Tools for the Rail & Utilities industries manufactured to British Standard BS 8020-2011.

Protecting Cables Against Strikes & Restoring Power Post-Strike

Thorne & Derrick have been distributors for 3M Electrical since 1985 and can provide a range of reliable and easy to install Cable Repair Products – this includes Scotch Tapes, Scotchcast Joints and Cold Shrink Tubes to provide effective re-instatement of cable sheath jackets on all types of LV MV HV cables in onshore and offshore locations with safe or hazardous area workplace classifications.

Cable Repair Products

Our range of cable protection covers manufactured by Centriforce provide underground utility protection of LV MV HV cables including Tapetile (11kV) and Stokbord (33kV 66kV 132kV) – contact us to discuss Cable Damage Prevention Products including Dectamesh, the underground detectable warning tape for alerting excavators of the presence of buried cables and to prevent potentially lethal accidents during excavation.

Cable Strikes | How To Support LV to 33kV Electricity Cables

May 11th, 2021

Cable Strikes

Utility Strike Avoidance Group

USAG have published a range of documents to assist industry understanding of the root cause and contributory factors behind specific incidents. The aim is to improve industry standards and reduce the number of cable strikes.

Cable damage is often caused by excavating machines – hand held tools such as pneumatic drills, crowbars, pins, picks and forks also expose workers to potential sources of danger when digging around underground cables.

The next in the series is a safety alert thanks to Highway England regarding incidents caused by contractors incorrectly supporting power cables.

Incident Overviews

Below are some case studies and a useful guide on how to support exposed LV to 33kV cables spanning your excavation, supplied by SP Energy Networks.

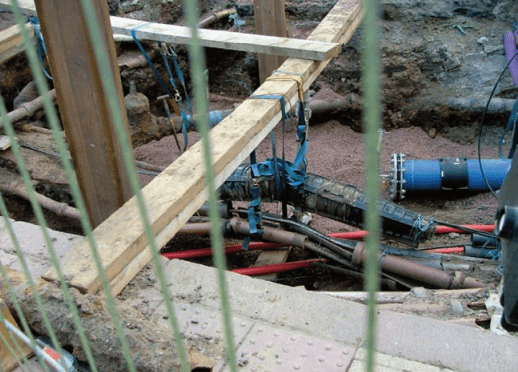

The above image highlights a situation which could easily be avoided if the correct planning processes had been implemented at the pre-construction phase of the project.

The task for the contractor was to expose the utilities and excavate a further 3 metres past the electrical network, leaving the low voltage (PILC) cable supported with rope at two locations.

The inadequate level of support of the electrical network at this location is not acceptable to ScottishPower; the contractor was advised to backfill the exposed cable with caution.

Given the ongoing mechanical excavations, lack of cable support and that contact with the electricity network was a possibility the contractor was advised to contact SP Energy Networks Customer Connections department to progress a cable deviation to remove the hazard.

The above image demonstrates how NOT to support an electricity cable.

The contractor has gone some way to supporting the Low Voltage cable in the correct way by using sturdy batons and ratchet straps, however the weakest part of the electrical network are the LV cable joints.

ScottishPower would recommend that exposed cables with joints should not be supported in this situation at any time due to the probability of the weight of the joints pulling the cables out of the joint connections. To carry out support of electrical cables a method statement and a safe system of work will be required by ScottishPower prior to works being undertaken.

The contractor has gone some way to supporting the underground network cables by using ratchet straps, however in this situation the cables are all bunched together and have sagged. The weakest part of the electrical network in this situation are the cable joints with the added weight of the exposed cables.

ScottishPower would recommend that exposed cables with joints should not be supported in this manor due to the probability of the weight of the joints/sag on the cables pulling the cables out of the joint connections. Every excavation has different dimensions to consider prior to carrying out work to support the electrical cables.

A method statement and a safe system of work will be required by ScottishPower prior to support works being required on the electrical network.

The above image highlights a situation which clearly highlights the incorrect method of supporting a live underground electrical cable.

The above image highlights a situation which clearly highlights the incorrect method of supporting a live underground electrical cable.

The inadequate level of support of the electrical network at this location was not acceptable to ScottishPower; the contractor was advised to support the exposed cable with caution to the correct ScottishPower requirements.

Given the ongoing mechanical excavations and the lack of adequate support, contact with the electricity network was a possibility the contractor was advised to contact ScottishPower EnergyNetworks Customer Connections department to progress a cable deviation to resolve the situation.

➡ Thorne & Derrick distributes Insulated Tools for the Rail & Utilities industries manufactured to British Standard BS 8020-2011.

The above image highlights a near miss situation which could have been easily avoided if the correct processes were implemented at the planning stage of the project, as opposed to attempting to rectify the avoidable situation at the construction phase.

On this occasion the project to construct an extension to an existing building had started, SP EnergyNetworks were contacted and advised the main contractor that the existing low voltage underground cable traversing through the foot print of the proposed extension would require to be deviated.

Further advice was delivered, highlighting that the existing cable should not be constructed over. The advice given was not adhered to and the contractors proceeded to excavate and install concrete foundations around the existing underground electrical network.

This course of action left the cable unprotected and open to the elements, the cable being concreted over at various locations and being supported in an unprofessional manor. During operations to excavate the foundations of the extension the electrical cable was damaged, fortunately on this occasion no injuries occurred to the operatives.

The above image demonstrates how not to support electricity cables.

The above image highlights a near miss situation which could easily have be avoided if the correct processes had been implemented at the planning stage of the project, as opposed to attempting to rectify the avoidable situation at the construction phase.

On this occasion the contractor progressed with the project despite being advised that a cable deviation would be required, and that the underground electrical network was not to be constructed over.

The contractor’s decision to progress construction placed operatives in danger which resulted in the low voltage cable being damaged. Despite the cable being damaged, excavations continued with the cable being exposed, covered in concrete and supported at various locations.

LV MV HV Voltage Detectors | Portable Earthing | Insulating Sticks | Insulating Gloves | CATU Electrical Safety Equipment

RAMS Generic Guidance For Supporting/Exposing/Operating Around SP EnergyNetworks Underground Distribution Electrical Cables:

33KV – High Voltage – Low Voltage Cables:

- Ensure all machine operators/site traffic drivers/operatives/visitors are made aware of all cable routes on construction site at initial site induction.

- Prior to works commencing, works area should be marked/highlighted (install signage at excavation location) to ensure all operatives are aware of the presence of the underground electrical network in the works area, this information also to be promoted continually throughout the remainder of the onsite works. (Task specific tool box talk also required prior to works commencing to ensure everybody understands the scope of works to be undertaken around the underground electrical network, their collective/individual roles to be clearly defined ensuring the required task is completed in a safe environment)

- Procure SP EnergyNetworks cable records (UMV System: Utility Map Viewer)

- Excavations as per HSG47 hand excavate to uncover all electrical cables/utilities in vicinity of proposed works.

- Supporting cables: If excavation length on electrical cables exceeds 1.2m cables will require to be supported.

- Install split cable ducting (150mm) around all exposed cables (for protection purposes only)

- No sudden movement of cables to take place. (minimum movement when placing split ducting around all cables)

- Provide substantial support beam above the cables, spanning across the exposed cable excavation, caution when placing/removing support beam. Ratchet straps are to be utilised to support the split ducted cables from the beam above.

- Ratchet straps to be of sufficient size/quality to support the weight of the split ducted cable, and are to be tensioned until they hold the ducted cables weight only, prevent any over strain on the ducted cables. Ratchet straps to be placed at 1m intervals.(Please note: no rope/string to be used to support underground cables)

- Once the ducted cables are sufficiently supported with the ratchet straps/supporting beam the hand excavation shall continue to clear 500mm beneath the existing cables. (Ensure the ducted cables will not sag at any exposed length of the cable)

- Cable records indicate no joints on cables at locus of proposed excavations, however if cable joints are located, excavation works to cease immediately and SP EnergyNetworks to be contacted for further guidance.

- Great care to be taken when installing the drainage pipe/other, that contact with the electrical network is avoided.

- Great care to be taken when installing/removing shoring/drag boxes etc that contact with the electrical network is avoided

- Caution to be taken when backfilling excavation around the existing cables, backfill to underside of cable, remove split ducting, sand cables with 150mm of sand, install marker tape.

- Continue to backfill with caution.

No SP EnergyNetworks cables to be supported at any time without SP EnergyNetworks authorisation. Contractors proposing to support the underground electrical network are to produce a risk assessment – method statement to formalise the advice described above to demonstrate to SP EnergyNetworks that risk assessments/method statements/safe systems of work will be implemented to ensure a successful conclusion to this stage of the project. The risk assessment/method statement shall be passed to SP EnergyNetworks for review/approval prior to excavation/supporting cable works commencing on site.

Cable Hangers | Cable Ducting | Cable Protection | Electrical Safety Equipment

Protecting Cables Against Strikes & Restoring Power Post-Strike

Thorne & Derrick have been distributors for 3M Electrical since 1985 and can provide a range of reliable and easy to install Cable Repair Products – this includes Scotch Tapes, Scotchcast Joints and Cold Shrink Tubes to provide effective re-instatement of cable sheath jackets on all types of LV MV HV cables in onshore and offshore locations with safe or hazardous area workplace classifications.

Cable Repair Products

Our range of cable protection covers manufactured by Centriforce provide underground utility protection of LV MV HV cables including Tapetile (11kV) and Stokbord (33kV 66kV 132kV) – contact us to discuss Cable Damage Prevention Products including Dectamesh, the underground detectable warning tape for alerting excavators of the presence of buried cables and to prevent potentially lethal accidents during excavation.

Cable Strikes | Excavator Struck 11kV Overhead Power Lines

May 11th, 2021

Cable Strikes

Utility Strike Avoidance Group

USAG have published a range of documents to assist industry understanding of the root cause and contributory factors behind specific incidents. The aim is to improve industry standards and reduce the number of cable strikes.

Cable damage is often caused by excavating machines – hand held tools such as pneumatic drills, crowbars, pins, picks and forks also expose workers to potential sources of danger when digging around underground cables.

The next in the series is a safety alert thanks to Highway England regarding incidents caused by contractors incorrectly supporting power cables.

A Striking Reminder

Incident Overview

Critical and immediate safety action from the Deputy Director Health, Safety & Wellbeing

During river maintenance work a 21 tonne long reach excavator fitted with a weed cutting attachment, came into contact with an uninsulated overhead electricity cable rated at 11,000 Volts / 11kV. Fortunately no one was injured and the utility company repaired the damaged cable that day. Due to the potential consequences this has been classified a Safety Critical Incident. We have reported this dangerous occurrence to the Health and Safety Executive, who have been in contact with us about the matter.

The initial facts point towards the importance of implementing our established control measures.

The full facts and lessons learned will emerge in the review that has begun. However, the incident is an important reminder of the significant hazard presented by overhead powerlines. I am therefore reminding colleagues who undertake, supervise or manage work involving mobile plant and equipment of the key precautions that must be taken when travelling under or working near overhead powerlines.

Operations Managers must:

Brief those members of their teams who plan, supervise and undertake tasks involving mobile plant and equipment, and remind them to:

- Obtain up to date services information from statutory utility providers before the work commences

- Include the information on services in the Pre-Construction Information and/ or site pack for the activity

- Provide information on services and other hazards on a single map or plan of the site

- Implement all of the control measures specified in the risk assessment before the works proceed

- Carry out a pre-start briefing so that risks, controls and method of work are communicated to colleagues undertaking the task

- When plant is operating within 15 metres of overhead power lines, ascertain the voltage and height of the cables. This information is essential in determining exclusion zones, stand-off distances and for setting of height limiter devices

By close of business on 15 September 2020 all Operations Managers must:

Please note Safeguard is not being used to issue actions due to reliability problems (we shall shortly be moving Group Actions to Airsweb).

As an interim measure;

Confirm that the action is completed and that the appropriate personnel have been briefed as requested by using the voting buttons on the notification email.

Remember; taking these actions could prevent a colleague being hurt or seriously injured – This action was approved by the review team on 8 September 2020

To support this action, active monitoring suggestions include:

- Check if services information is included in site packs

- Ask site teams if they know the voltage and height of the overhead power lines they are working near or travelling under

- Check quality of site maps and plans to see if hazard information is included

Cable Strikes | Cable Hangers | Cable Ducting | Cable Protection | Electrical Safety Equipment

Protecting Cables Against Strikes & Restoring Power Post-Strike

Thorne & Derrick have been distributors for 3M Electrical since 1985 and can provide a range of reliable and easy to install Cable Repair Products – this includes Scotch Tapes, Scotchcast Joints and Cold Shrink Tubes to provide effective re-instatement of cable sheath jackets on all types of LV MV HV cables in onshore and offshore locations with safe or hazardous area workplace classifications.

Cable Repair Products

Our range of cable protection covers manufactured by Centriforce provide underground utility protection of LV MV HV cables including Tapetile (11kV) and Stokbord (33kV 66kV 132kV) – contact us to discuss Cable Damage Prevention Products including Dectamesh, the underground detectable warning tape for alerting excavators of the presence of buried cables and to prevent potentially lethal accidents during excavation.

Cable Strikes | The Utility Strike Avoidance Group (USAG)

March 17th, 2021

Cable Strikes

Cable Strikes

A Series of Articles Republished Kind Permission of USAG

Utility strikes represent an ever-present threat to human life.

Hundreds of people have died across the World as a result of strikes on underground and overhead cables and pipelines – the 2019 Utility Strike Damages Report 2019 summarises the key findings of approximately 2500 utility strikes across the UK based on responses from 44 USAG Members. It highlights what caused the most damages and provides scope and recommendations to:

✓ Avoid future damages

✓ Improve the ability to analyse the strike data in future years.

The main conclusions for the causes were:

▪ Better preparation in advance of breaking ground / construction works commencing. This should be through availability of more accurate plans and the use of more robust location and survey practices

▪ Behavioural issues on site during the execution of the works is a key issue; it is recommended that the root causes are established and investigated further

Articles

- High Pressure Gas Main Strike Failure Upper Thames Crossing

- Cable Strikes | Gas and Electric Service Strikes

- Cable Strikes | How To Support LV to 33kV Electricity Cables

- Cable Strikes | Excavator Struck 11kV Overhead Power Lines

- Cable Strikes | Strike to Low Voltage Cable

- Cable Strikes | Surface Cable Damage by Mower

- Cable Strikes | Damage to Underground Service

- Cable Strikes | Combined Gas and Electric Strike and Ignition

- Cable Strikes | Ingrebourne Valley – 415V Cable Strike

- Cable Strikes | 132kV Cable Strike at Sellafield

- Cable Strikes | 10kV Medium Voltage (MV) Cable Struck By An Excavator

- Cable Strikes | 11kV Strike With Auger

- Cable Strikes | 11kV Depot Cable Strike

- Cable Strikes | HV Cable Joint Explosion