Duct Seals

GIS Substation Cable Duct Sealing To Protect HV High Voltage Power Systems

December 17th, 2024Water Ingress in GIS Substations

A dry cable basement achieved by cable duct sealing is a cornerstone of reliable GIS (Gas Insulated Switchgear) substation operation – substations provide electricity distribution for both medium (MV) and high voltage (HV) power systems in the UK typically distributing electrical power at 11kV, 33kV, 66kV and 132kV voltages.

Water intrusion, even in limited volumes, can have severe and catastrophic consequences to the provision of uninterrupted LV MV HV power supply:

Corrosion: Water ingress and flooding accelerates cable corrosion including metal components compromising the structural integrity of the substation

Electrical Faults: Water can bridge insulation, leading to short circuits, arcing, and potential substation fires

Reduced Equipment Lifespan: Moisture can degrade insulation materials and accelerate equipment aging

Operational Disruptions: Water ingress through unsealed cable ducts can necessitate unplanned maintenance and outages, impacting power delivery

Prevention is Key | Cable Duct Sealing

To safeguard GIS substations, implement these preventive measures:

Robust Drainage Systems: Ensure effective drainage to divert water away from the substation basement.

Waterproof Cable Duct Sealing: Regularly inspect and maintain ducting seals on cable entries plus doors, and other openings.

Regular Inspections: Conduct routine inspections to identify and address potential water ingress points.

Emergency Response Plans: Develop and implement contingency plans for water intrusion events.

By prioritizing a dry cable basement, you can enhance the reliability, safety, and longevity of your GIS substation, MV HV cables and electrical infrastructure – view our complete range of duct seals.

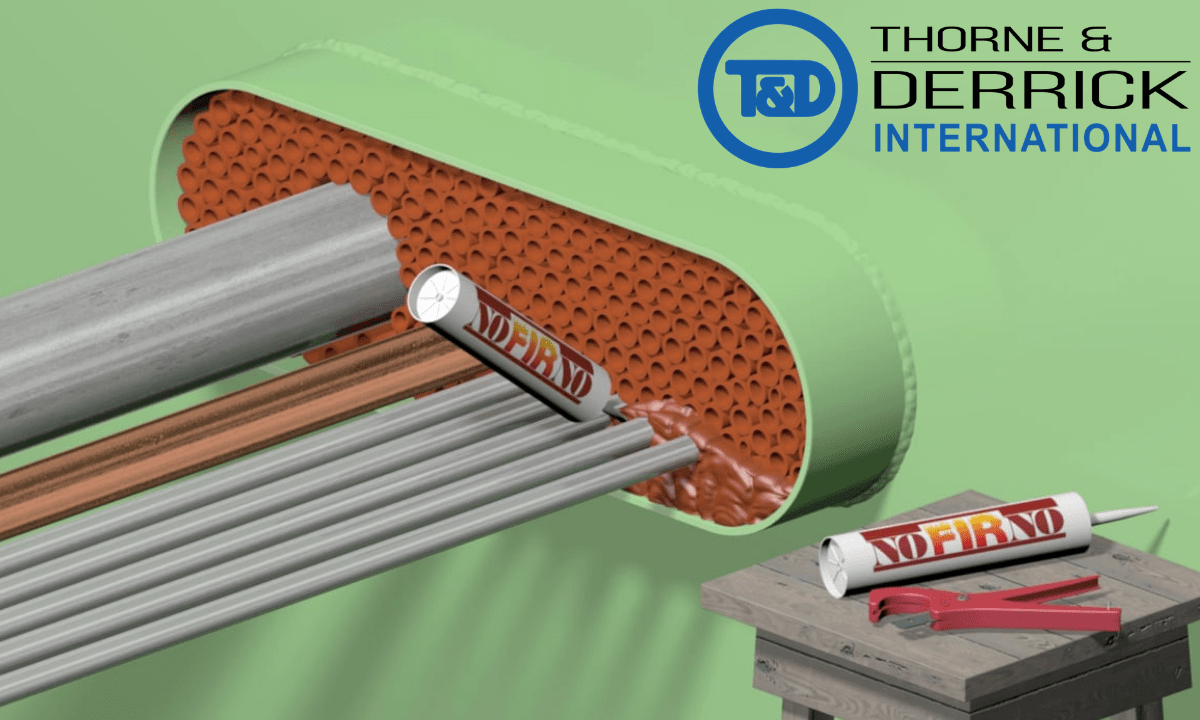

The NOFIRNO Duct Seal System is the proven choice for watertight and gas-tight protection for cable ducts, manhole entries, duct bank entries, and similar applications to prevent flood damage to GIS substations on the UK DNO and private network.

Use of NOFIRNO Duct Sealing Systems in Pump Manufacturing

January 2nd, 2024

NOFIRNO Duct Sealing

Pump Manufacturing Sealing

The CSD NOFIRNO is a Single & Multi Pipe Penetration Sealing System – one of the most adaptive systems for sealing straight and angled pipe penetrations and can even accommodate multiple pipe runs, significantly saving in space and weight.

To help adoptable pumping stations meet the required UK water authority standard, CSD’s NOFIRNO Duct Sealing system ensures that any duct sealing complies with the specifications.

It is included with many design specifications used by pump manufacturers, pump suppliers and installation contractors of adoptable pumping stations.

NOFIRNO Systems

The NOFIRNO Duct Seal system comprises of two components; 60mm rubber NOFIRNO multi-sleeves which provide cable support, ensure cable separation, and provide a backing for the second component, which is a 20mm layer of NOFIRNO Sealant.

Ensuring the NOFIRNO Sealant adheres correctly, the areas where the sealant is to be applied, should be clean and dry before application i.e., the cables and any frames/structures.

The NOFIRNO multi-sleeves are installed which provides cable separation and a firm backing for the NOFIRNO Sealant layer.

Benefits of using Nofirno dUCT SEALS

- Simple and easy to install

- Supported by inspection, design and installation services

- Stops rodents from damaging cables or equipment

Further Reading

- 66kV 72.5kV | Power Cables Accessories for Offshore Windfarms

- Supplying Cable Termination, Jointing, Pull-in & Electrical Equipment up to 66kV

- CSD Marine Grade Cable Transit Sealing System Supplied Onboard Kintra II Passenger Vessel

More Case Studies

- Sealing Cables | Windfarm & Substation Cable Sealing using CSD Systems

- Sealing Cables | 400kV Substation Cable Sealing using CSD Systems

- Sealing Cables | Decarbonisation & Storage Depot Case Study

THORNE & DERRICK are national distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, copper earth tapes and substation earthing at LV, 11kV, 33kV and EHV.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Stockists & Suppliers | UK & International Projects

Filoform MD5 Duct Sealing System Vs DIY Expanding Foam

January 2nd, 2024Filoform MD5 Sealing System

vs DIY Expanding Foam

Most UK utilities have banned the use of expanding foam as a measure to effectively seal cable ducts against water ingress, gas migration or fire spread. Failure to correctly and safely seal cable ducts can inflict catastrophic damage to LV MV HV Electrical Distribution Networks, Substations and Power Supply.

Thorne & Derrick International are the UK distributors for Filoform, a leading manufacturer of cable joints, duct seals and special resins for installation in the utilities, telecom, traffic, rail, fibre optic, street lighting and construction industries.

Polyurethane foam (PU) has witnessed a increase in popularity as a construction material due to its versatility. PU can be applied to walls, roofs, ceilings, floors providing insulation and structural support. Technological advancements have overcome engineering challenges, allowing for low-density foam products that are easy to install on-site.

Duct Seals – Sealing Cable Ducts

uSING Filoform MD5 Duct Sealing VS DIY expanding foAM

Whilst expanding foam serves well for sealing small gaps, filling voids, cracks and insulating it falls short beyond these applications. Often comprised of subpar polyurethane, many expanding foams lack the necessary properties for effective sealing or adhesion.

The use of expanding foam in construction and maintenance projects across various industries have grown over time; however it faces major problems when applied wrong, or designed into a project where the foam specifications doesn’t match the requirements of the projects.

Comparing MD5 Duct Sealing Resin to Generic expanding foam

Assessing the particular duct seal scenario and determining the project’s goals are important when selecting an efficient seal. Taking into account elements such as :

- Cable Presence

- Water blocking specifications

- Fire Stop standards

- Building entrance points

- Gas and chemical problems

During the design phase choosing a sealing system that fits the needs of the entire project should be made easier by taking the circumstances into consideration.

Sealing Ducts require precision, a professional would strongly advise against using DIY expanding foam for this purpose due to potential complications. For guidance in your inquiries please contact us today!

| Properties | Generic expanding foam – DIY stores | MD5 Duct Sealing Resin – Two Components |

| Cell Structure | Large, Weak, soft foam – 70% closed | 100% closed, small, strong, durable |

| Expansion Rate | 35 x can volume – Very quick & controlled | 8 x volume – Slow & easy to control |

| Temperature Resistance | +194°F / +90°F | +248°F / +120°F |

| Compressive Strength | 3 Newton / cm² / 0.67 pounds of force | 60 Newtons / 14 pounds of force |

| Resistance to Hydrocarbons | No | Yes |

| Water Resistant | Yes – temporarily | Yes permanently – upto 1.5 bar / psi |

MD5 Sealing System vs DIY Expanding Foam | FILOFORM

hOW TO SELECT A DUCT SEAL SOLUTION

It is important to evaluate specific duct sealing situation and identify the objectives of the seal. For example:

- Is there cables in the duct and how many?

- Does water need to be blocked? How much water?

- Is a firestop needed?

- Does the conduit enter the building?

- Are gases or chemicals a concern?

This process should take place during the design phase aligning the seal requirements with the overall product specifications. Generally, a design specification will encompass gas, water and fire resistance along with specified chemical resistance. However any reputable seal manufacturer should be able to furnish evidence regarding the expected lifespan.

Key to an effective seal

- Training and preparation – read and follow manufacturers instructions. This requires knowledge and skill.

- Sealing system selection – most underground duct sealing systems will need to block water and gases and tolerate hydrocarbons. If the duct enters the building, a fire stop may be required so you need to select a sealing system that addresses the risk present.

- Cable separation – this is a area where most duct seals will fail ; either the product doesn’t support cable separation, or the installer has been unable to separate the cable sufficiently. Without separation, water and gases will simply wick through areas without the sealant.

- Conduit sealing – our range of conduit sealing systems have been designed to provide a simple and effective solution for watertight and gas sealing of pipes and cables in conduits, boreholes and ducts. Conduit sealing systems can be installed horizontally and vertically; they are very flexible.

Key Benefits of using an effective Duct seal

- Allows for low density foam to use

- Used in many places .

- Made of good quality polyurethane foam material

Duct sealing and sealing products manufactured by Filoform are installed to provide gas tight and watertight sealing for cable duct entries – protecting underground cables and substation ducting infrastructure against flood and migration of flammable and toxic gas hazards. Fire resistant version also available – suitable for sealing LV-HV power, telecoms and fibre optic cables.

Filoform manufacture and supply quality products and solutions to connect, seal and protect low, medium and high voltage underground cable networks.

Thorne & Derrick provide competitive prices and fast delivery from stock for the complete range of Filoform duct seals and cable joints.

View the complete range of Filoform products.

FiloSeal+HD Duct Sealing System

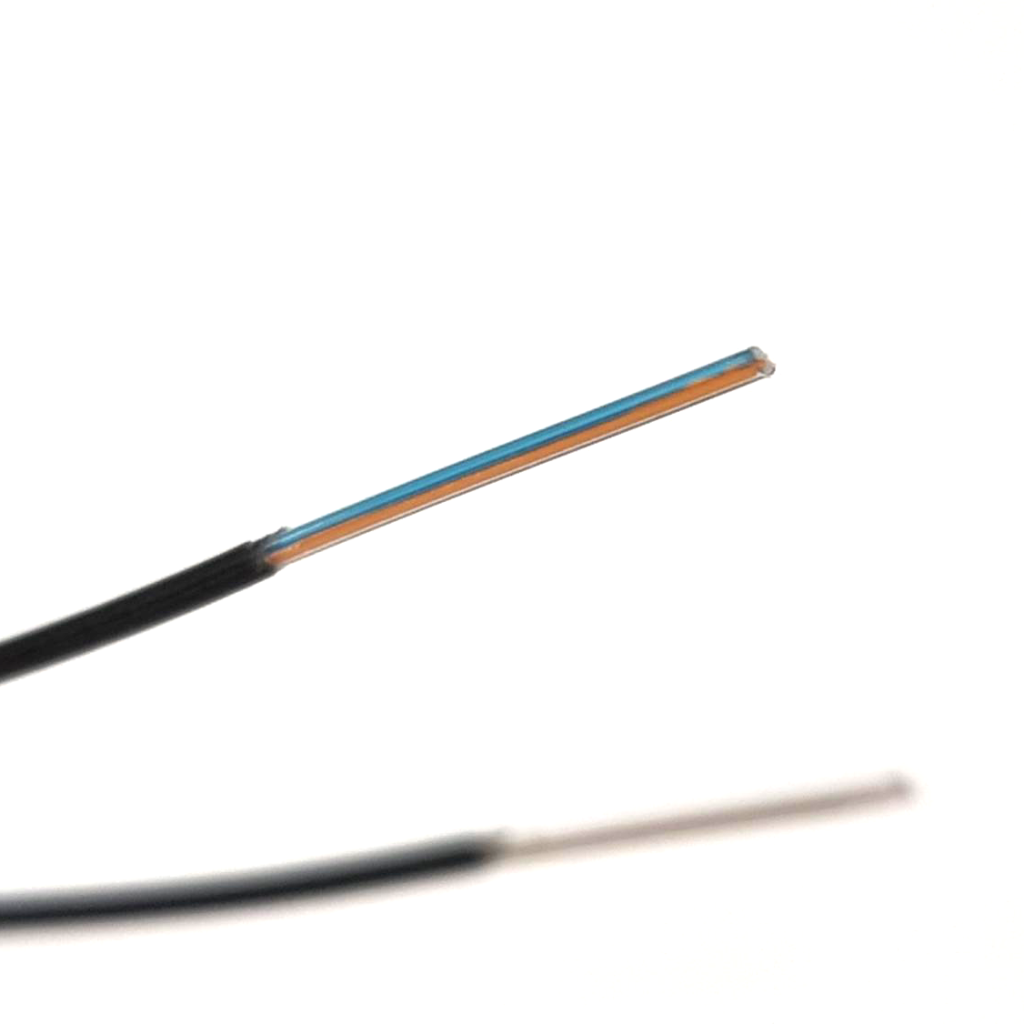

Emtelle Fibrecast Microcable | Redefining Connectivity, Revolutionising Networks

October 31st, 2023

Emtelle | Fibrecast Microcables

Fibrecast Microcables

Fibre Unit (FU) with fibres set in an encapsulating layer providing excellent dimensional and thermal stability. An outer thermoplastic layer provides a high level of protection and excellent installation properties.

The FU is manufactured by Emtelle as a fibre element for installation into FibreFlow products. The fibres are dry, not coated with gel, thus permitting fast and contamination –free connections.

Fibrefast Microcable | Emtelle

Microcabling

An outer layer provides a high level of protection and excellent installation properties. The Microcable is designed for installation into FibreFlowTM duct products.

Emtelle’s microcable contains ‘low water peak’ single mode fibres meeting the ITU-T (International Telecommunications Union) recommendation G.657A2, G.657.A1 fibre is also available.

Outcome of using Microcables

FibreFastTM boasts an impressive 8% improvement in friction coefficient over our FibreFlow microcable. Rigorously tested on Emtelle’s test track, the innovative FibreFastTM results in superior blowing performance. With over 25 years of experience in manufacturing fibre cable solutions.

FibreFastTM microcable now features improved tensile performance making this product ideal for our pre-terminated blowable fibre cable solutions.

Fibrefast Microcable | FTTx | Emtelle

Fibrecast Microcable

Emtelle have developed the FibreFast microcable to improve the overall installation experience by reducing installation time (Ultra Low Friction Sheath) and equipment specification (lower installation pressure required) depending on the infrastructure quality.

FibreFast microcable now features improved tensile performance making this product ideal for our pre-terminated blowable fibre cable solutions and this is distributed by Thorne and Derrick.

The microcable is well suited to the FTTx market, where it excels as a blowable terminated solution. It has applications in 5G/FTTA (antenna)/IoT, distributions network infrastructure and FTTH (home) as a blowable customer connection cable.

Deployed in 2.1mm – 5.0mm internal diameter microduct infrastructure.

Also it has these key features:

- Perfect blowable customer connection cable when paired with Emtelle QWK connect

- Small is size meaning even better storage

- Assembles the LCv ferrule in under 30secs – Intuitive build compared to others on the market

Key Benefits from Alroc

- Superior blowing performance at low blowing pressure

- Improved durability – strong and lightweight cable.

- Tested in accordance with IEC 60794-5-20

Further Reading

- Sealing Cables | Decarbonisation & Storage Depot Case Study

- Sealing HV Cables | A Battery Energy Storage Systems (BESS) Case Study

- Sealing Cables | 400kV Substation Cable Sealing using CSD Systems]

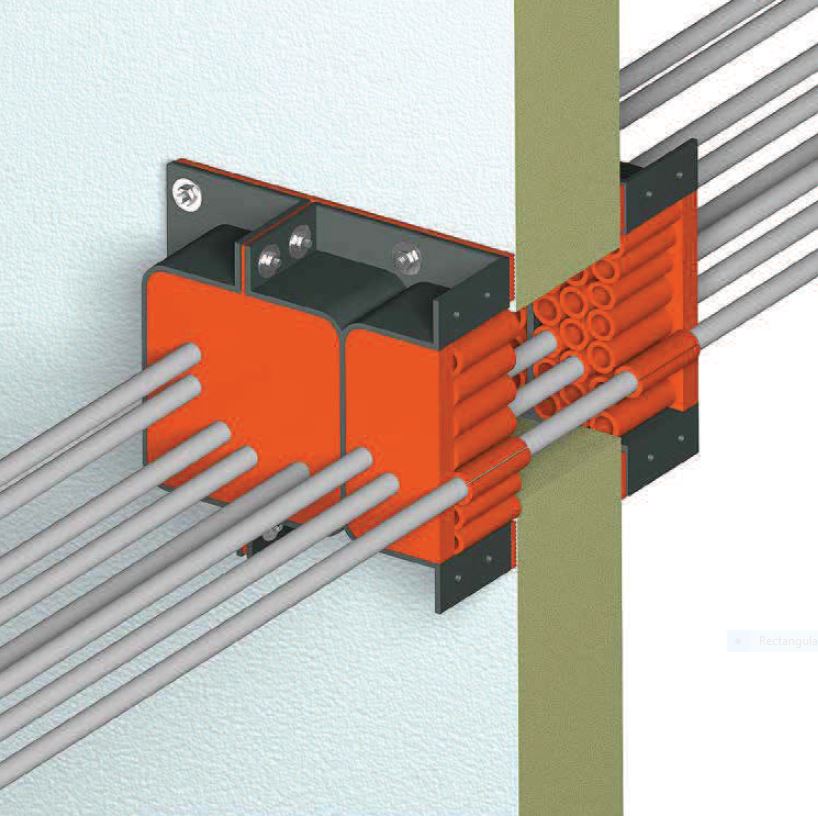

CSD Penetration Systems | Facility Fireproofing Case Study

October 26th, 2023

CSD | Penetration Sealing Systems | NOFIRNO

HR Fireproofing Sealing

CSD were contracted to supply and install the HR Conduit Sleeves and NOFIRNO firestopping system at the site. The project had a requirement to maintain a 60-minute fire integrity requirement for all cable and pipe entry penetrations passing through Cross Laminated Timber (CLT) panels used within the wall construction.

The selected solution for the CLT wall type was a HR-frame sealed with NOFIRNO firestopping systems.

NOFIRNO | HR Frame | Penetration Systems

Facility Fireproofing

There were various challenges when it came to designing and installing a solution suitable for sealing the pipe and cable penetrations through the CLT wall panels. The solution had to ensure that the 60-minute fire rating was maintained when the panels were penetrated by any service passing into each unit. During CSD’s installation onsite, we worked alongside the M&E contractors to ensure that completion of each unit could be signed off on time.

Outcome of using Penetration systems

The penetration seal design with HR-frames and with NOFIRNO penetration seal system achieved fire resistance of more than 60 minutes. All openings were successfully sealed by CSD’S installation team and the project handed over on target.

Nofirno Penetration System

The NOFIRNO cable and pipe penetration system comprises of only a few components.

A correctly fitting NOFIRNO cable sleeve is placed around each cable, any free space around any services is packed using NOFIRNO multi sleeves before completing the seal with a 20mm layer of NOFIRNO sealant at each end of the penetration.

To ensure the NOFIRNO Sealant adheres correctly, the areas where the sealant is to be applied should be clean and dry before application. Furthermore for example any pipes or cables, and any frames or the building structure.

The system will provide a fire rated, water and gastight seal and has been shown to provide protection for a period of at least 50 years.

HR Penetration fRAMES

CSD’s HR penetration frames are designed for use in composite or sandwich panels. They allow cable or pipes to penetrate the panel. CSD’s NOFIRNO Penetration Sealing System will ensure the fire integrity of the panel is maintained.

The HR frames are available in a range of circular and rectangular sizes. It can be easily adjusted to suit the thickness of the panel.

key Benefits of Penetration Systems

• Assured to prove no deterioration in performance for more than 50 years

• Provides flood protection and prevents water and gas ingress. The pressure rated up to 2.5 from the front and back of the seal

• Quick and easy to install

• Easy re-entry for adding, removing or replacing cables

Further Reading

- 66kV 72.5kV | Power Cables Accessories for Offshore Windfarms

- Supplying Cable Termination, Jointing, Pull-in & Electrical Equipment up to 66kV

- CSD Marine Grade Cable Transit Sealing System Supplied Onboard Kintra II Passenger Vessel

More Cable Sealing Case Studies

- Sealing Cables | Decarbonisation & Storage Depot Case Study

- Sealing HV Cables | A Battery Energy Storage Systems (BESS) Case Study

- Sealing Cables | 400kV Substation Cable Sealing using CSD Systems]

Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service. Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Stockists & Suppliers | UK & International Projects