Duct Seals

Sealing Cables | Decarbonisation & Storage Depot Case Study

October 26th, 2023.

Substation Cable Sealing

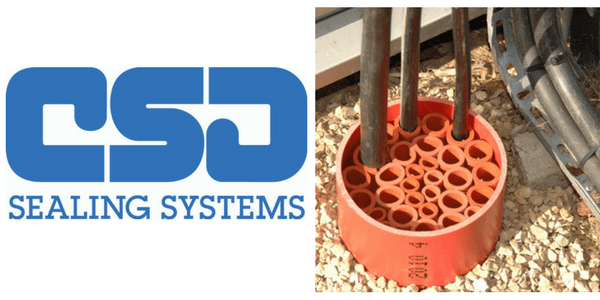

Thorne & Derrick are Approved Distributors for CSD Sealing Systems – we have specified and distributed their products across numerous onshore and offshore substation projects.

CSD Technical Services were recently contracted to carry out water and gastight sealing of cable entry points.

This was on a DNO substation at a council maintenance and storage depot. This was also a part of an action plan to reduce carbon emissions across the site.

Using CSD’S NOFIRNO Duct Seal System distributed by Thorne and Derrick, it has successfully sealed all entry points, helping to prevent any water or gas ingress in the building.

Completing the seal with a 20mm layer of NOFIRNO sealant will provide a technically advanced and high performance duct seal. View the complete range of CSD Sealing Systems to protect against damage caused by water ingress, gas spread or fire/flame to cables and ducts.

NOFIRNO | Substation Sealing | CSD The NOFIRNO Duct Seal is designed to provide simple and effective long term building entry sealing protection. The system can be used in new build projects or in retrofit applications to replace existing failing seals. It can be installed directly into concrete openings, plastic ducting or into any existing transit frames.

Substation Duct Sealing

The site remained operational throughout the installation, with CSD working alongside and in partnership with other contractors and existing site workers. The NOFIRNO Duct Seal System was the selected solution for sealing the entry points.

Outcome of using the NOFIRNO Seal System

All entry points into the substations were successfully sealed using CSD’s NOFIRNO Duct Seal System to prevent any water or gas ingress within the building.

This was to ensure the site remained operational. The openings within the control room which consisted of 37 x 160mm cable ducts and a 1 x 690mm x 900mm cable entry, was sealed along with a 1 x 230mm x 430mm cable entry in the DNO building.

A second visit to site was made to remove 1 x 150mm installed seal following the installation of an additional cable. This seal was then resealed using the NOFIRNO Duct Seal System. The client feedback was very positive, and they will be looking to use CSD for future projects.

NOFIRNO Duct Seal System

The NOFIRNO Seal System comprises of two components; 60mm rubber NOFIRNO multi-sleeves which providing the cables with support, ensuring separation.

It helps provide a backing for the second component which is a 20mm layer of NOFIRNO Sealant. To ensure the NOFIRNO Sealant adheres correctly, the areas where the sealant is to be applied should be clean and dry before application.

For example the cables and any frames and structures. The NOFIRNO multi-sleeves are then installed providing cable separation and a firm backing for the NOFIRNO Sealant layer.

NOFIRNO duct seals consist of rubber multi sleeves which are in bonded strips of 10 sleeves and a high quality silicone based sealant which are quicker and easier to install than the CSD standard RISE duct seals.

The bonded sleeves can be easily torn off for filling smaller gaps and using cutting tool sleeves can be quickly slit to allow fitting around cables ensuring cable separation – NOFIRNO duct seals are also used to pack the free space, providing a backing for the application of the cable sealant.

Key Benefits of Duct Seal Systems

• Tested to prove no deterioration in performance

• Provides flood protection and prevents water and gas ingress. The pressure is rated up to 2.5 bar from the front and back of the seal.

• Quick and easy to install

• Easy re-entry for adding, removing or replacing cables

Further Reading

- 66kV 72.5kV | Power Cables Accessories for Offshore Windfarms

- Supplying Cable Termination, Jointing, Pull-in & Electrical Equipment up to 66kV

- CSD Marine Grade Cable Transit Sealing System Supplied Onboard Kintra II Passenger Vessel

More Cable Sealing Case Studies

- Sealing HV Cables | A Battery Energy Storage Systems (BESS) Case Study

- Sealing Cables | 400kV Substation Cable Sealing using CSD Systems

- Sealing Cables | Windfarm & Substation Cable Sealing using CSD Systems

Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service. Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Stockists & Suppliers | UK & International Projects

Sealing HV Cables | A Battery Energy Storage Systems (BESS) Case Study

October 24th, 2023

Battery Energy Storage System

CSD’s Technical Services were contracted to carry out water and gastight sealing of cable entry points across the site including the BESS, LVAC and NGET units. The NOFIRNO Duct Seal system, manufactured by CSD Sealing Systems and distributed by Thorne and Derrick, was the favoured solution for sealing HV cables.

The NOFIRNO Duct Seal System was used to provide a water and gastight seal to certified levels of 2.5 bar.

Battery Energy Systems

A site suffered from significant water ingress and required external excavation to some of the buildings to ensure the required watertight seal would be obtained. CSD’S Aquastop system was also used on several internal seals.

Sealing Cables Using NOFIRNO For BESS Projects

All entry points were successfully sealed across the site using CSD’s NOFIRNO Duct Seal System. All buildings are now water and gastight helping to prevent water ingress and reduce the risk of equipment damage.

nofirno Duct Seal

The NOFIRNO Duct Seal system comprises of two components; 60mm rubber NOFIRNO multi-sleeves which provide cable support, ensure cable separation, and provide a backing for the second component, which is a 20mm layer of NOFIRNO Sealant.

To ensure the NOFIRNO Sealant adheres correctly, the areas where the sealant is to be applied, should be clean and dry before application i.e., the cables and any frames/structures.

The NOFIRNO multi-sleeves are then installed which provides cable separation and a firm backing for the NOFIRNO Sealant layer.

Outcome of using a NOFIRNO Duct Seal

All entry points were successfully sealed across the site using CSD’s NOFIRNO duct seal systems.

All buildings are now water and gastight helping to prevent water ingress and reduce the risk of equipment damage.

Key Benefits Of Duct Seals

• Tested to prove no deterioration in performance for more than 50 years

• Provides flood protection and prevents water and gas ingress – pressure rated up to 2.5 from the front and back of the seal

• Quick and easy to install

• Easy re-entry for adding, removing or replacing cables

NOFIRNO Duct Seal | Cable Sealing Solutions from CSD

Further Reading

- 66kV 72.5kV | Power Cables Accessories for Offshore Windfarms

- Supplying Cable Termination, Jointing, Pull-in & Electrical Equipment up to 66kV

- CSD Marine Grade Cable Transit Sealing System Supplied Onboard Kintra II Passenger Vessel

More Case Studies

- Sealing Cables | Windfarm & Substation Cable Sealing using CSD Systems

- Sealing Cables | 400kV Substation Cable Sealing using CSD Systems

- Sealing Cables | Decarbonisation & Storage Depot Case Study

THORNE & DERRICK are national distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, copper earth tapes and substation earthing at LV, 11kV, 33kV and EHV.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Stockists & Suppliers | UK & International Projects

Sealing Cables | 400kV Substation Cable Sealing using CSD Systems

October 24th, 2023

NOFIRNO | Sealing Substation Cables | 400kV High Voltage (HV)

Water & Gastight Cable Sealing

CSD Sealing Systems were recently contracted to carry out water and gastight sealing of cable ducts on a newbuild High Voltage substation project where the previously installed seals were leaking.

The NOFIRNO® Duct Seal System was used to successfully seal all entry points so that all buildings were water and gastight, helping to prevent water ingress, reduce the risk of equipment damage and ensure the site remains operational.

CSD Technical Services were contracted to carry out water and gastight sealing of cable entry points on this new build substation project. This substation would prove to be one of the largest built substations built across the UK and would ensure the transmission of renewable energy generated from a new offshore windfarm.

The NOFIRNO Duct Seal is designed to provide simple and effective long term building entry sealing protection. The system can be used in new build projects or in retrofit applications to replace existing failing seals. It can be installed directly in to concrete openings, plastic ducting or into any existing transit frames.

Sealing Substation Cables

The previously installed seals were leaking and therefore the client was concerned regarding the damages these leaks could bring to their assets. The NOFIRNO Duct Seal system, manufactured by CSD Sealing Systems and distributed in the UK by Thorne & Derrick, was the preferred solution to prevent flood damage to the high voltage (HV) cables and electrical infrastructure.

Outcome of Using Duct Seal Systems

All previous sealing materials were carefully removed ensuring that no cables were damaged during the removal. Following removal of the failing seals our team thoroughly cleaned all cables and the duct openings to remove all old sealant and any dirt, dust, and concrete.

All entry points were successfully sealed across the site using CSD’s NOFIRNO Duct Seal system. All buildings are now water and gastight helping to prevent water ingress and reduce the risk of equipment damage and ensure the site always remains operational.

nofirno seal system

The NOFIRNO Duct Seal system comprises of two components; 60mm rubber NOFIRNO multi-sleeves which provide cable support, ensure cable separation, and provide a backing for the second component which is a 20mm layer of NOFIRNO Sealant.

To ensure the NOFIRNO Sealant adheres correctly, the areas where the sealant is to be applied should be clean and dry before application i.e., the cables and any frames/structures. The NOFIRNO multi-sleeves are then installed providing cable separation and a firm backing for the NOFIRNO Sealant layer. The system will provide a water and gastight seal to certified levels of 2.5 bar and has been shown to provide protection for a period of at least 50 years.

Key benefits of duct seal systems

• Tested to prove no deterioration in performance for more than 50 years

• Providing flood protection and preventing water and gas ingress – pressure rated up to 2.5 from the front and back of the seal

• Quick and easy to install

• Accessible re-entry for adding, removing or replacing cables

HV Substation | Cable Sealing

Further Reading

- 66kV 72.5kV | Power Cables Accessories for Offshore Windfarms

- Supplying Cable Termination, Jointing, Pull-in & Electrical Equipment up to 66kV

- CSD Marine Grade Cable Transit Sealing System Supplied Onboard Kintra II Passenger Vessel

More case studies

- Sealing Cables | Windfarm & Substation Cable Sealing using CSD Systems

- Sealing Cables | Decarbonisation & Storage Depot Case Study

- Sealing HV Cables | A Battery Energy Storage Systems (BESS) Case Study

Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service. Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

See how T&D support, supply and service the Renewable Energy industry.

Stockists & Suppliers | UK & International Projects

CSD Marine Grade Cable Transit Sealing System Supplied Onboard Kintra II Passenger Vessel

October 18th, 2023

Thorne & Derrick | Stockists & Leading UK Distributor for CSD Sealing Systems

PR | Uploaded by Natalie Lundie | Supply Chain: Marketing Lead at Thorne & Derrick

Thorne & Derrick, a UK Specialist Distributor for CSD Sealing Systems, have recently supplied a technical solution to Rathlin Ferry for their Kintra II passenger vessel.

Together with CSD we provided a cable duct sealing system suitable for marine and offshore environments – protecting against flood water and gas ingress where cables are often routed through cable transits that are exposed to harsh weather conditions and potential flooding.

Sealing Application

The client contacted Thorne & Derrick requiring a solution that provided a safe and secure way to seal and protect cable and pipe penetrations through the bulkheads. The bulkheads that they were looking to pass cables through were rated at A60 and any system installed also needed to be A60 rated to maintain the integrity. The system also needed to provide fireproof and watertight seals that complied with International Maritime Organisation (IMO) and SOLAS regulations.

Thorne & Derrick contacted CSD, The Global Leader in Fire, Water & Gas Penetration Sealing Systems who initiated a consultation with the client to identify the optimum solution. After an extensive call with CSD’s Operations Director, Anthony Jordan discussing the application further it was decided that the original enquiry for Rise Duct Seals was more suited to the onshore market and a suitable alternative was offered.

CSD NOFIRNO Seals – Multi Cable & Pipe Transit Sealing

Sealing Solution

It was determined that the NOFIRNO Multi-Cable Transit System which is approved for harshest fire ratings for pipe penetrations (A, H and Jet Fire class) was the best solution.

This is because this type of system holds the required certification and provided the A60 rating required. Designed specifically to maintain the safety of the vessel by providing fire protection and ensuring the bulkheads remain gas and watertight when cables need to pass through them.

The NOFIRNO system comprises of rubber and filler sleeves and sealant, the system is used to treat transit openings for cables and pipes in walls, floors, bulkheads or decks, so that it is fire-resistant and sealed against gas, smoke and water.

It consists of only a few components: NOFIRNO sealant; a silicone based fire resistant, water repellent sealant, a correctly fitting NOFIRNO cable sleeve and NOFIRNO multi-filler sleeves, supplied in bonded strips to make the system easy to install.

The system consists of a correctly fitting NOFIRNO rubber sleeve placed around each cable with the free space then packed with rubber multi filler sleeves. The rubber sleeves are 40mm shorter than the overall transit length to allow the seal to be completed with a 20mm layer of sealant at each end of the transit.

Anthony Jordan Operations Director at CSD Sealing Systems commented, “We were pleased to support Thorne & Derrick, our Specialist Distributor, with the technical aspects of this enquiry helping to make ensure the customer was provided with a sealing solution that met their specification requirements and also provided a certified system to help improve safety and protect lives when the vessel is in service.”

CSD NOFIRNO Seals – Multi Cable & Pipe Transit Sealing – Installation Layout

Why did the existing frame need extending?

During the phone consultation with Anthony it was discussed that to meet the requirements of an A class fire rating the existing frame needed to be extended from the existing120mm in length. The system is tested at a minimum length of 180mm for A60 and 200mm for A0.

Anthony confirmed that CSD generally recommend using a 200mm to ensure all ratings are covered. The length of the penetration helps to prevent heat transfer between compartments and also ensures you have sufficient rubber materials for the system to perform when there is a fire.

It is imperative to ensure that not only there is no fire breakthrough where these cables pass through the bulkhead but also that the heat on the non-fire side does not increase to a level where there could be ignition on the non-fire side.

NOFIRNO Multi-Cable Transit System Advantages

The NOFIRNO system consists of high-quality, non-toxic silicone-based rubber seals and high-strength steel frames. The rubber seals are designed to expand and fill the space around the cables, providing a tight seal that prevents fire and smoke from spreading throughout the ship. The frames are designed to securely hold the seals in place and provide a strong and durable barrier against fire and water.

Using the NOFIRNO multi-cable transit system on a passenger vessel can provide many benefits, including:

- Enhanced safety and protection: The NOFIRNO system provides a high level of fire resistance and watertightness, ensuring that passengers and crew are protected from potential hazards

- Easy installation: The system is easy to install and requires minimal tools and equipment. This reduces installation time and costs, making it an efficient and economical option for shipbuilders and owners

- Flexibility: The system can accommodate a wide range of cable and pipe sizes, and can be customized to fit the specific needs of each vessel

- Durability: The NOFIRNO system is made from high-quality materials that are designed to withstand the harsh marine environment and provide long-lasting performance

With its proven track record of success, this CSD system is an excellent choice for anyone looking to protect their cables from the damaging effects of flood water and gas ingress.

KINTRA II

Kintra II was commissioned by Kintra Boat Tours in 2020.

It is an 82 passenger catamaran for trips and tours of the North Coast and Rathlin Islands. As the design of Kintra proved so popular with guests, Kintra Boat Tours decided to keep the same design with a few added extras.

Rathlin Island, Northern Island

Staff & Support Training Day | Anthony Jordan (Operations Director) has supported T&D for over 20 years. Anthony recently invited the team to visit the CSD offices in Cramlington providing product refresher and hands on training for the team.

LV HV | Jointing, Earthing, Substation & Electrical Eqpt up to 66kV | Specialist Distributors

MV HV High Voltage Cable Joints | Cable Terminations | Cable Connectors | Distributed from Stock | UK & Export Sales

Thorne & Derrick distribute the most extensive range of MV HV Medium & High Voltage Cable Joints, Terminations & Connectors from manufacturers including 3M, Prysmian, Nexans Euromold, Elastimold, Pfisterer CONNEX & SEANEX.

Heat shrink, cold shrink, push-on and slip-over cable accessories enable the jointing, terminating and connection of 11kV-33kV and 66kV-132kV cables to oil, air or gas insulated switchgear, transformers, motors and overhead lines distributing electricity at MV HV.

Thorne & Derrick hold large stocks of 11kV 33kV 66kV Joints, Terminations & Connectors suitable for XLPE, PILC and EPR cables, in both heat shrink and Cold Shrink technologies, to service the medium/high voltage power cable accessory requirements of UK and international customers – this includes underground and subsea cables.

Fire Rated A0-A60 Sealing using SLIPSIL Sealing Plugs

August 30th, 2023SLIPSIL Sealing Plugs

Designed for single service penetrations through A0-A60 fire rated bulkheads and decks, SLIPSIL sealing plugs manufactured by CSD Sealing System combine fast and simple installation with effective sealing performance against fire, gas and water ingress.

• Allows easier pipe routing and saves valuable space

• Suitable for sealing metallic and all plastic pipe systems

• Allows for pipe movement

• Reduced noise signature

• Shock and vibration proof reducing stress on pipework systems

• Easy to replace pipe systems during future works

View more information about A60 Sealing systems.

CSD Sealing Systems

CSD Sealing System (UK) have specialised in the supply and installation of technically advanced cable transits, flexible pipe penetrations and RISE and Nofirno cable duct seals within the UK for 30 years. The product range is suitable for applications within the naval, shipbuilding, offshore and onshore construction industries and is also widely used across the utility and nuclear industry. The systems can provide up to 4 hours of fire protection, will offer the highest levels of flood protection and gastight integrity and are proven to provide in excess of 50 years long term sealing protection. CSD are the UK representative of Beele Engineering BV, a company with over 50 years’ experience in the development and production of penetration sealing systems. Beele Engineering’s research, testing and production facilities are amongst the most advanced in the world, and all products manufactured under strict quality controls with the NOFIRNO, SLIPSIL and RISE Ultra Crusher systems having CE approval. CSD are ISO9001:2015 certified and aim to provide the highest levels of service and support to our customers, assuring first class products and first class service whatever the industry. Our highly skilled and experienced team are available to discuss all of your requirements for cable transit and pipe penetration sealing.

CSD NOFIRNO Duct Seals – Multi Cable & Pipe Transit Sealing