Arc Flash Protection & Electrical Safety | 15 Measures to Mitigate the Hazards of Arc Faults

Published 12 Apr 2022

Arc Flash Protection & Electrical Safety Products | Distributed By Thorne & Derrick

Arc flash Protection

An arc flash is the light and heat produced as part of an arc fault; a type of electrical explosion or discharge that results from a low impedance connection through air to ground or another voltage phase in an electrical system.

In industries working around high and low voltage electricity, the importance of Electrical PPE and arc flash protection is widely recognised, and the latest electrical safety requirements are understood by managers and operatives alike.

However, the dangers posed by an arc flash are not so well known in comparison. With temperatures of up to 35,000ºF, which is more than four times hotter than the surface of the sun, an arc flash has the potential to burn an operative’s skin within fractions of a second, meaning PPE really is the last line of defence for workers.

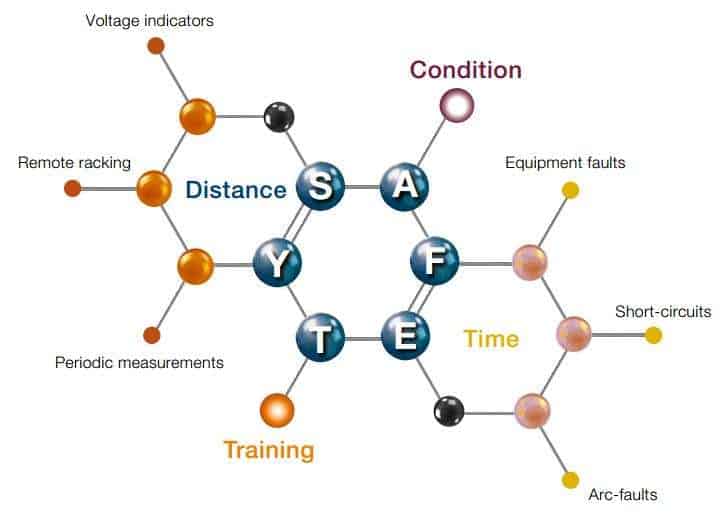

In the face of the internal arc fault risk present in low and medium voltage switchgear, prevent accidents to protect the personnel and the electric installation itself by following this proven formula.

Condition

Knowing and improving the condition of the equipment is a key factor in reducing the likelihood of failure, damage, and injury. is comprised of condition, distance, time, and training.

- Risk Assessment study – Asset risk assessments to establish the risk profile of equipment based on its condition and importance in the system, and prioritize actions to mitigate the risk before the hazard occurs

- Monitoring programs – Risk monitoring and mitigation programs to maximize improved reliability and reduced operator exposure

- Upgrades and retrofit – Equipment upgrades and retrofit which decrease operator exposure because of reduced maintenance, faster cycle times, and lower clearing times

- Diagnostic testing – Diagnostic testing to address concerns of bad connections, pollution, mechanical faults and minimize failures due to defective devices

Distance

Maintaining a safe distance between personnel and equipment during critical operations provides the most effective means of avoiding injury by keeping people out of harm’s way

- Remote racking – Remote racking provides a safer operating environment for personnel through the proven method of adding distance between the operator and arc flash incident energy at the switchgear site, bringing operation of power circuit breakers to a new level of safety. ABB vacuum circuit breakers can be provided with a fully integrated motor operated racking system for their use in new replacement switchgear or as part of the hard-bus and cradle-in-cradle retrofill solutions.

- Voltage indicators – The installation of voltage indicators on accessible power circuits can increase the operators safety and avoid accidental electrical contact injuries. VisiVolt is an ABB passive voltage indicator perfectly suiting the equipment upgrade. It is adapted for permanent installation on busbar and naked or insulated metal conductors, indicates the presence of voltage by displaying a large and well visible lightning arrow sign on its display. The relevant silicone elastomeric enclosure ensures performance also in outdoor conditions while its fluorescent orange colour provides good visibility among the other elements of the system.

- Infrared thermo-graphic inspection – Infrared (IR) thermal measurements are performed through dedicated arc-proof ports with power compartment doors closed. The periodic thermo-graphic inspection of the critical areas (e.g. power cables connections) is an efficient method for preventing associated faults. Ports can be added to existing switchgear by ABB expert engineers keeping the original equipment design characteristics.

- Partial discharge measurements – Periodic measurement of the partial discharge (PD) level is a proven method for detecting insulation degradation before real insulation failure develops. The assessment results are documented as trend curves for each switchgear compartment, where the curves with high increase of partial discharge activity level indicate compartments with high risk of insulation failure. Site work is performed with closed doors.

Time

Reduction of time for clearing fault conditions has a dramatic impact on the energy released and consequent damage and injury.

- MV equipment faults: relay upgrades with Relion® – microprocessor equipment which operate faster than electromechanical relays and support faster clearing times.

- Short-circuit current: Is-Limiter device – Is-limiter device as a fast operating interrupting device that limits the short circuit current to a level that breakers and buses can withstand, protecting property and personnel. Replacement of existing switchgear and cable connections with new equipment with higher short-circuit ratings can be technically impossible. The use of Is-limiters reduces the short-circuit current in extensions of existing systems and in new systems. The Is-limiter is capable of detecting and limiting a short-circuit current during the first current rise in less than a millisecond.

- Arc-faults: REA arc fault detection system – REA arc flash protection relay uses patented fiber-optic sensor technology that instantaneously detects light from an arc to signal a “trip” to the designated circuit breaker in less than 2.5 ms, minimizing an arc flash incident.

- Arc-faults: Upgrade with UFES – UFES, an ultra fast earthing switch, provides detection and grounding of faults in times significantly faster than breaker clearing times, leading to the avoidance of injury and damage and the reduction of production outages. A device as small as an insulator offers enhanced protection for your switchgear by the effects of internal arcs. The UFES arc protection system channels the uncontrolled release of energy by the arc into a solid metal, 3-phase connection to earth potential. The internal arc will be extinguished within an operation time of < 4ms after detection of the fault.

Training

Adequately trained personnel and proper procedures are essential to safe operations

- Personnel training – Training engineering and technical services provide personnel with a better understanding of their equipment and systems and the safest means to operate them.

- Procedure development – Arc flash studies help to determine the necessary level of protective equipment or clothing (PPE) to be worn by workers in close proximity to potential arcs and also help determine the proper application of any arc flash protection equipment to be installed.

- Engineering studies – Engineering studies determine the proper settings and system coordination, while addressing the speed of the system to handle a fault so relays and associated protective devices are set properly in order for the system to react as designed.

Electrical Safety Providers

We protect substation engineers, asset managers, SAPS, cable jointers, overhead linesmen and utility workers with PPE and safety equipment: this includes insulating gloves, arc flash clothing, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out repair and maintenance on LV-HV switchgear, transformers, substations and turbines.

All of our Cable Connection & Energisation Accessories including Medium & High Voltage joints, terminations, connectors and cleats are tested to the latest international standards and supporting ranges of professional installation tools are stocked to reduce incident, accident and downtime to plant and people.