Black C8 Wire Mesh Cable Tray for Hazardous & Aggressive Cable Containment from Pemsa

Published 02 Mar 2020

Black C8 Wire Mesh Cable Tray | Pemsa

-

Guest Information from Pemsa

Black C8

Wire Mesh Cable Tray

Pemsa has developed a high resistance coating for rejiband® wire mesh tray which provides an excellent resistance to corrosion in wet and aggressive environments.

High Corrosion Resistance

Demonstrated with more than 1000 hours in the neutral salt spray tests and obtained through a new manufacturing process that improves both the barrier effect against the aggressive media and the ability of self healing in damaged areas. With the result obtained in the neutral salt spray test, more than 850 hours, the corrosion resistance is classified as Class 8, according to Table 9 of the current standard BS EN 61537 trays.

BS EN 61537

This International Standard specifies requirements and tests for cable tray systems and cable ladder systems intended for the support and accommodation of cables and possibly other electrical equipment in electrical and/or communication systems installations. Where necessary, cable tray systems and cable ladder systems may be used for the division or arrangement of cables into groups.

Salt Spray Test Duration

| Class | Duration |

| 0 | – |

| 1 | 24 |

| 2 | 96 |

| 3 | 155 |

| 4 | 195 |

| 5 | 450 |

| 6 | 550 |

| 7 | 700 |

| 8 | 850 |

Duration (h) Salt Spray Chamber Chamber Test – acc. ASTM-B117

Certified High Resistance

rejiband® BLACK C8 has obtained the AENOR N Marking (Spanish Association for Standardization and Certification) and the certification IECEE CB Scheme of IEC (International Electrotechnical Commission), garanting the Class C8 of resistance against corrosion, with more than 1000 hours on the Salt Spray Test.

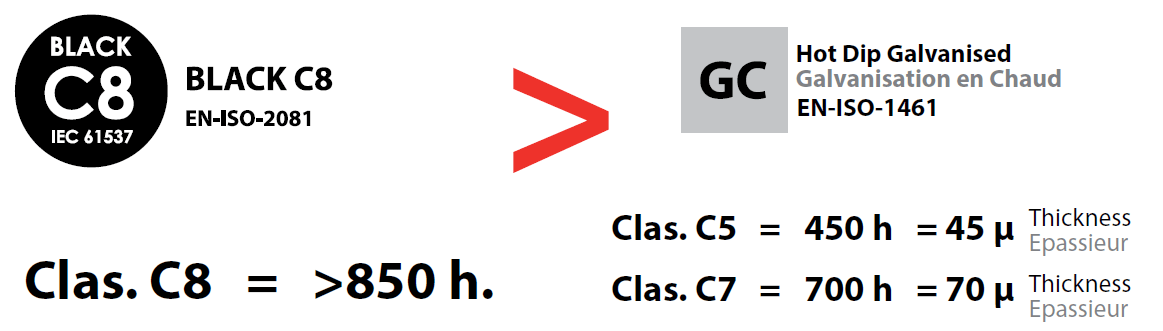

BETTER FEATURES THAN HOT DIP GALVANISED

Hot dip galvanised normally ranges from between 45 to 70 microns mean coating thickness, so it should be Class 5, 6, or 7, having a lower corrosion resistance than BLACK C8.

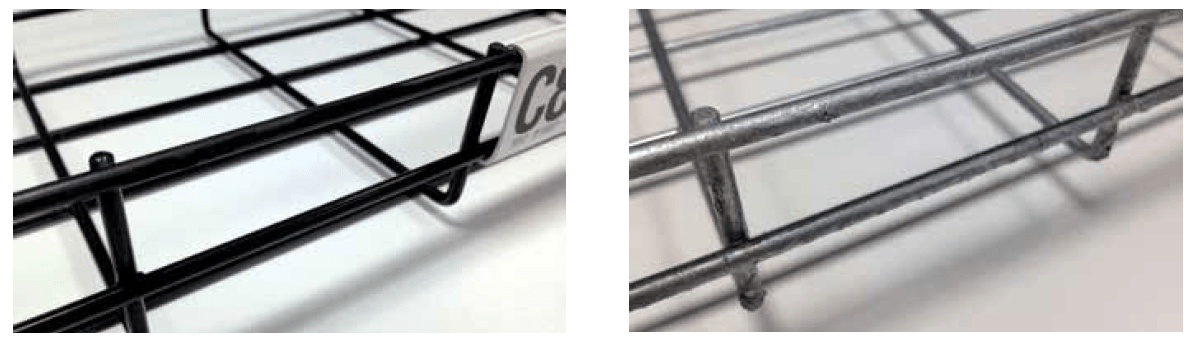

Aesthetic appearance

The smooth finish is much more aesthetic than that of hot dip galvanised.

- No sharp edges or ends

- No irregularities or areas with reduced thickness

- Black colour provides excellent aesthetics which are suitable for decorative applications, commercial facilities, false ceilings, etc.

Electrical continuity

This coating maintains the electrical continuity of rejiband®, complying with the requirements of BS EN 61537 standard for cable tray system with electrical continuity characteristics. This feature allows bonding to other exposed conductive elements and, in case of a fault, the evacuation of electrical currents to the earth.

The most appropriate coating for Data Centres

BLACK C8 coating avoids the emergence of the phenomenon of Zinc Whiskers, or loosening of filaments of zinc, which can be a serious problem within the electronics of clean rooms in Data Processing Centres.

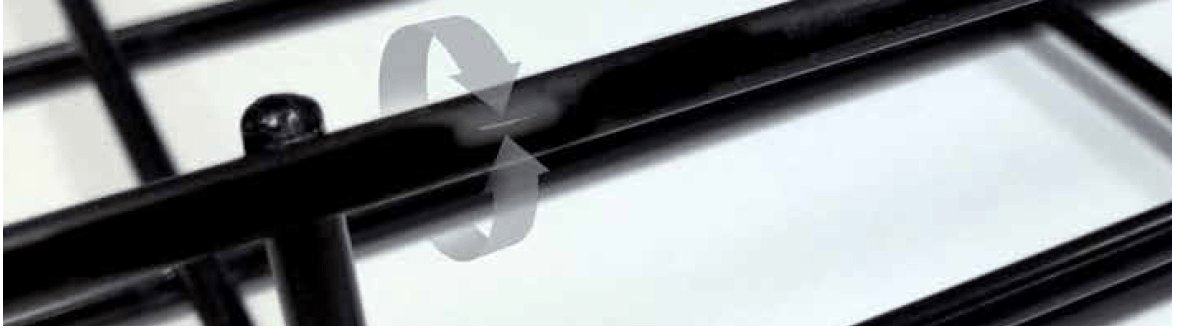

Increased capacity for selfhealing, or self-repairing, of the protective layer

The characteristics of self-healing, or self regeneration, on scratches, minor defects or in the cutting of the wire, are remarkably better than that of the zinc.

Excellent ductility

It is possible to bend the the tray without causing any damage to the finish. These features retain the properties of flexibility and the forming of accessories with rejiband®, bends, level changes, in any format.

Environmentally Friendly

The BLACK C8 coating is manufactured in a process which significantly reduces energy consumption and waste generation over other coatings which consume more resources like hot dip galvanised.

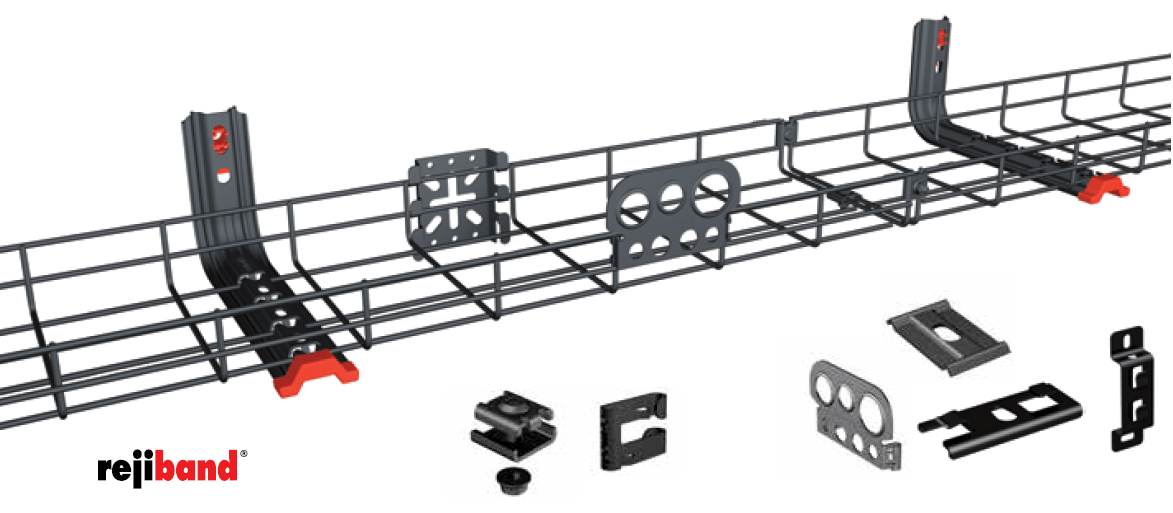

Full Range of brackets and accessories

rejiband® BLACK C8, product range includes a complete catalogue of accessories and supports, providing a high corrosion resistance and a better visual aspect to the whole installation. This system offers the same corrosion resistance of Class C8 for everything, improving the performance of the system against aggressive environments and enhancing the performance of a hot dip galvanized finish, where accessories and brackets do not reach this classification. The system is complemented by the use of a black colour zinc spray that is suitable for the protection and aesthetic improvement of cut rods and possible damage caused during installation.

| Black C8 Wire Mesh Cable Tray Reference | Description | Pack (m) |

| 60282060 | REJIBAND 60×60 C8 | 24 |

| 60282100 | REJIBAND 60×100 C8 | 24 |

| 60282150 | REJIBAND 60×150 C8 | 24 |

| 60282200 | REJIBAND 60×200 C8 | 18 |

| 60282300 | REJIBAND 60×300 C8 | 12 |

| 60282400 | REJIBAND 60×400 C8 | 6 |

| 60282500 | REJIBAND 60×500 C8 | 6 |

| 60282600 | REJIBAND 60×600 C8 | 6 |

| 64080030 | CLICK CONNECTOR C8 | 30 |

| 64080035 | FAST CLICK JOINT C8 | 50 |

| 64080036 | FAST CLICK BASE JOINT C8 | 10 |

| 64080041 | SIDE JOINT PLATE C8 | 50 |

| 64080059 | SERRATED HEXAGON FLANGE NUT C8 | 50 |

| 64080060 | PART CLAMP C8 | 50 |

| 64080061 | REINFORCED JOINT CLAMP C8 | 50 |

| 64080072 | FAST CLIP C8 | 50 |

| 68000053 | BLACK Zinc Spray 400 ml | 1 |

| 67080030 | LUMINAIRE AND BOX SUPPORT C8 | 10 |

| 67080040 | CONDUIT GLAND BRACKET C8 | 10 |

| 67080043 | CLICK CENTRAL SUSPENSION M8/M10 C8 | 20 |

| 67080046 | CENTRAL HANGING PLATE M8/M10 C8 | 20 |

| 67080053 | SPLICE PLATE C8 | 10 |

| 67080143 | CLICK CENTRAL SUSPENSION M6 C8 | 20 |

| 62081060 | SIDE SUPPORT 60 C8 | 25 |

| 62086010 | MINI UNIVERSAL BRACKET C8 | 10 |

| 62086011 | UNIVERSAL BRACKET C8 | 10 |

| 62086020 | LIGHT DUTY CEILING SUPPORT C8 | 10 |

| 62086021 | LIGHT DUTY WALL SUPPORT C8 | 25 |

| 62086022 | BASE SUPPORT 60 C8 | 10 |

| Black C8 Wire Mesh Cable Tray Reference | Description | Pack (m) |

| 62081104 | OMEGA SPLUS BRACKET 100 C8 | 5 |

| 62081154 | OMEGA SPLUS BRACKET 150 C8 | 5 |

| 62081204 | OMEGA SPLUS BRACKET 200 C8 | 5 |

| 62081304 | OMEGA SPLUS BRACKET 300 C8 | 5 |

| 62081404 | OMEGA SPLUS BRACKET 400 C8 | 5 |

| 62081504 | OMEGA SPLUS PENDANT 500 C8 | 5 |

| 62081604 | OMEGA SPLUS PENDANT 600 C8 | 5 |

| 62082104 | OMEGA SPLUS CEILING BRACKET 100 C8 | 4 |

| 62082154 | OMEGA SPLUS CEILING BRACKET 150 C8 | 4 |

| 62082204 | OMEGA SPLUS CEILING BRACKET 200 C8 | 4 |

| 62082304 | OMEGA SPLUS CEILING BRACKET 300 C8 | 4 |

| 62082404 | OMEGA SPLUS CEILING BRACKET 400 C8 | 4 |

| 62085103 | MEDIUM DUTY CANTIL. R PLUS 100 C8 | 4 |

| 62085153 | MEDIUM DUTY CANTIL. R PLUS 150 C8 | 4 |

| 62085203 | MEDIUM DUTY CANTIL. R PLUS 200 C8 | 4 |

| 62085303 | MEDIUM DUTY CANTIL. R PLUS 300 C8 | 4 |

| 62085403 | MEDIUM DUTY CANTIL. R PLUS 400 C8 | 4 |

| 62085503 | MEDIUM DUTY CANTIL. R PLUS 500 C8 | 4 |

| 62085603 | MEDIUM DUTY CANTIL. R PLUS 600 C8 | 4 |

| 63082104 | OMEGA CHANNEL SPLUS 100 C8 | 10 |

| 63082154 | OMEGA CHANNEL SPLUS 150 C8 | 10 |

| 63082204 | OMEGA CHANNEL SPLUS 200 C8 | 10 |

| 63082304 | OMEGA CHANNEL SPLUS 300 C8 | 10 |

| 63082404 | OMEGA CHANNEL SPLUS 400 C8 | 10 |

| 63082504 | OMEGA CHANNEL SPLUS 500 C8 | 10 |

| 63082604 | OMEGA CHANNEL SPLUS 600 C8 | 10 |

APPLICATIONS

Tunnels & Industry

Photovoltaic & Shopping Centres

Waste Treatment Plants & Data Centres

LV, MV & HV JOINTING, EARTHING, SUBSTATION & ELECTRICAL EQPT

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.