Lovink Cable Joints & Network Resilience at 11kV & 33kV

Published 23 Apr 2025

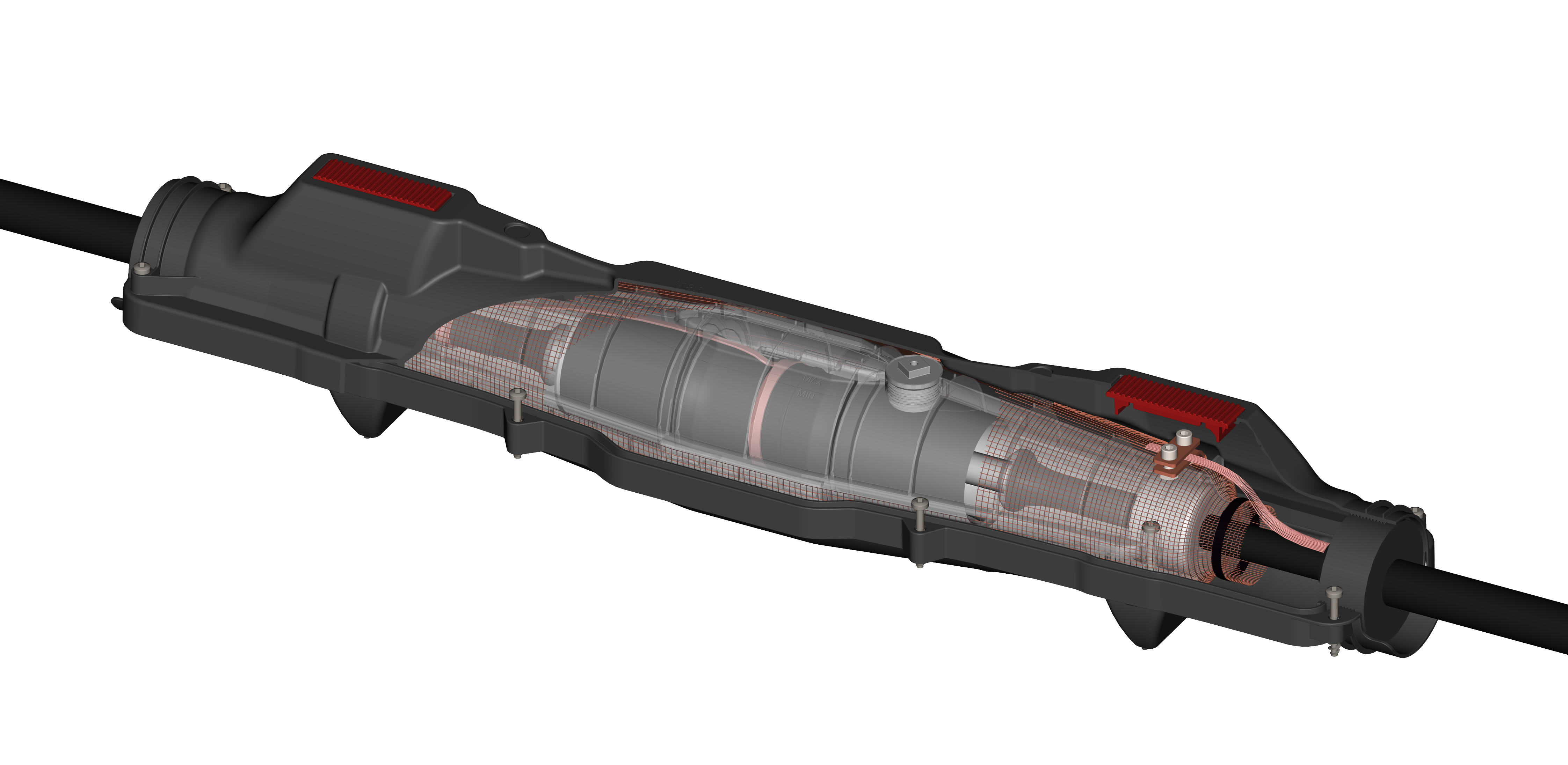

Cable Jointing Solutions

Network resilience requires advanced technology solutions manufactured from highest performance materials; if high harmonics, Sine wave distortion, AD8 protection, abnormal thermal cycling, high-water table, ALE of legacy PILC or general cable failure prevention to critical 11/33kV circuits matters to you, then talk to us.

Where cables undergo dynamic cyclical load in high harmonic and non-linear load applications the Lovink range of cable joints demonstrate years of fault-free field performance in high temperature installations – additionally, the cable joints are “flame-free” and therefore safe for installation in potentially explosive atmospheres as no heating source or naked flame is required for the installation.

Resin encapsulation provides the highest levels of mechanical impact protection and electrical insulation eliminating voids, discharges and ionisation within the cable joint – the seawater resistant resin and “wet area” (2 bar at 20m water head) performance counters premature electrical cable joint failures in the renewable sector where damp soil conditions, flooded duct and water immersion can induce premature service failure to jointing solutions utilising other technologies.

The compact design permits reduced size joint holes reducing excavation and associated civil engineering preparation costs – ideal for confined space applications where volume displacement is a factor and close quarter working necessitates a compact profile solution.

Thank you to Stephen Davies (Lovink Enertech Account Manager) for todays emphatic Presentation and roundtable with our incredible Team.

Lovink Cable Joints

For straight, transition and branch connections of MV Power Cables – this includes 11kV and 33kV paper-insulated (PILC/PICAS) and polymeric (XLPE/EPR) cables up to 1000sqmm.

Lovink Cable Joints