Submersible Switch Applications By G&W Electric

Published 07 Jan 2021

Submersible Switch Applications

G&W Electric

The following Case Study by G&W Electric and presented by Thorne & Derrick describes the features of submersible switch applications in underground distribution systems.

Thorne & Derrick are Specialist Distributors of Substation, Electrical Safety, Cable Jointing & Accessories to UK and international utilities and contractors providing electrical power at distribution and transmission voltage levels.

G&W Electric Submersible Vault Switches are totally submersible to IP68 standards and offer the following additional features:

Construction: Compact, dead-front construction

Cable Entrance: Cable entrance flexibility, either top, bottom, side or front

Standards: Designed to international industry standards

Interrupting Capability: Load and fault interrupting capability

Configurations: Multi-way configurations

Operating Options: Options for operation outside the vault

Insulation: SF6 or solid deielctric insulation

Ratings: Ratings through 38kV, 25kA symmetric

Designs: Fully automated designs

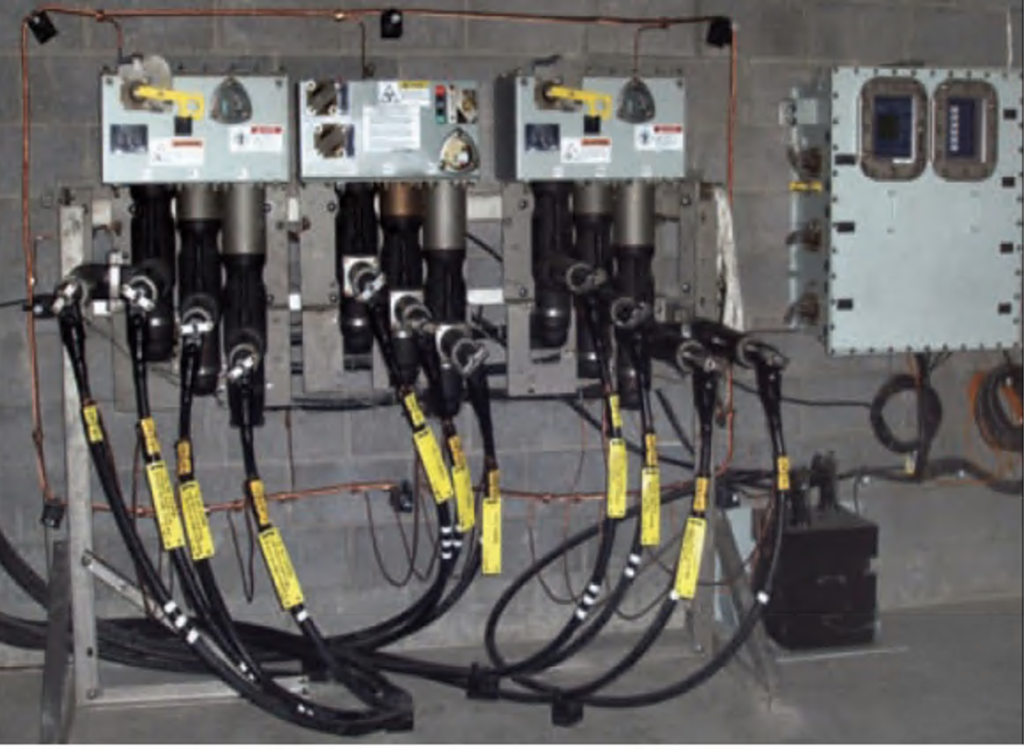

Submersible switch installed in a small, under- ground vault, subject to flooding

In underground distribution systems, electrical cable is either direct buried or fed through conduit and connected to electrical apparatus installed in either padmount enclosures or buildings above ground or in concrete vaults below ground.

Underground cables can be direct buried or installed in conduit to switch locations.

Underground vaults can be small or large, and either dry or subject to submersion. Underground systems offer many benefits compared to overhead systems including:

• A much cleaner installation site

• No more unsightly poles

• No more damage due to ice, wind or wildfire

• No more sagging lines which can sway in the wind, causing an overcurrent condition

Three-way, solid dielectric, automatic transfer switch with submersible control cabinet and potential transformers.

Top operable switch after submersion in water.

Solid dielectric switch installed in vault.

G&W ELECTRIC

Overview of G&W Cable Accessories

In 1905 G&W introduced the first disconnectable cable terminating device.

Over 100 years later, G&W continues to create technical innovations that have improved performance and reliability. With over 100 years experience, G&W is the name you can trust for quality cable accessories. With sales representation worldwide, G&W has a proven track record for success.

G&W cable accessories are designed to accommodate cables from all manufacturers and can be created to accommodate any customer cable system. The optional mechanical shrink feature offers an easier and faster installation while reducing possible damage during installation. G&W also offers installation supervision and installation training, which can be customized to suit the audience.

G&W offers a variety of transmission cable accessories for extruded dielectric cable systems. Cable terminations are available for outdoor applications to 230kV and include porcelain or composite insulator options and premolded designs. Gas insulated substation designs are available to 230kV.

Transition cable splices and cable joints are available to 138kV and include premolded designs. All cable terminations and cable joints incorporate built-in stress control and dielectric fluid. Dry type designs are also available for maximum ease of installation.