Nofirno Sealing System Successfully Tested for Use in Explosive Environments

Published 13 Jul 2021

Nofirno

NOFIRNO systems are used to seal cable ducts in an extensive range of Process industry sectors including the fine and speciality chemicals, petrochemicals, pharmaceuticals, hydrogen and polymers manufacturing sectors. The NOFIRNO range of duct seals are used to protect against water ingress, gas migration, fire spread and rodent infestation into electrical substations and buildings through LV MV HV cable ducting systems.

ATEX directive requirements can be imposed for specific uses in hazardous area locations (Zone 1/2 Flammable Gas & Zone 21/22 Combustible Dust) where there is a potential risk of explosion. Kiwa has thus investigated the extent to which the NOFIRNO sealing system (from Beele Engineering) fulfils ATEX directive 2014/34/EU.

Comprised of rubber and filler sleeves and sealant, the system is used to treat transit openings for cables and pipes in walls, floors, bulkheads or decks, so that they are fire-resistant and sealed against gas, smoke and water. Kiwa’s research has shown that NOFIRNO is extremely suitable for use in environments such as those covered by the ATEX directive and described in the European standard EN 1127-1 ‘Explosive atmospheres – Explosion prevention and protection – Part 1: Basic concepts and methodology’.

Because the NOFIRNO sealant, NOFIRNO rubber sleeves and the complete NOFIRNO sealing system do not fulfil an autonomous role and are not equipment in the sense of the ATEX directive, the risk evaluation focused on use of the NOFIRNO in cable and pipe transits. All possible ignition sources related to the sealing system were also investigated.

Among the possible ignition sources which were assessed, were hot surfaces, flames and hot gases (including hot particles), mechanically-generated sparks, electrical equipment and power leakages, cathodic corrosion protection, static electricity, lightning, electromagnetic and ionising radiation, ultrasonic sound waves, adiabatic compression and shockwaves and exothermic reactions, including materials self-igniting.

Kiwa concluded that for all hazardous situations as described in EN 1127-1, there is no ignition source for NOFIRNO sealant, NOFIRNO rubber sleeves, NOFIRNO rubber filling sleeves and the complete, installed NOFIRNO system.

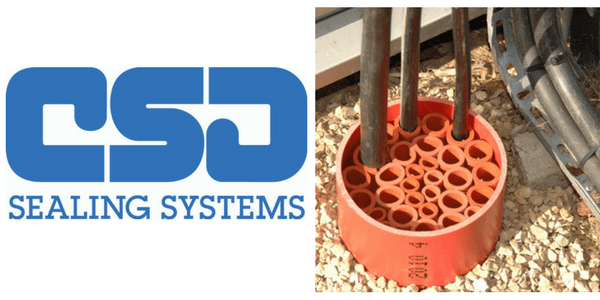

CSD NOFIRNO DUCT SEAL SYSTEM

Watertight, Gastight & Fire Protection & Sealing for Cables & Duct Entries

CSD NOFIRNO duct seals is a multi-cable and pipe transit sealing system designed specifically for cable duct seals and building entries providing an effective and simple solution protecting against flood water and gas ingress.

NOFIRNO duct seals consist of rubber multi sleeves which are in bonded strips of 10 sleeves and a high quality silicone based sealant which are quicker and easier to install than the CSD standard RISE duct seals.

The bonded sleeves can be easily torn off for filling smaller gaps and using cutting tool sleeves can be quickly slit to allow fitting around cables ensuring cable separation – NOFIRNO duct seals are also used to pack the free space, providing a backing for the application of the cable sealant.

Completing the seal with a 20mm layer of NOFIRNO sealant will provide a technically advanced and high performance duct seal. View the complete range of CSD Sealing Systems to protect against damage caused by water ingress, gas spread or fire/flame to cables and ducts.

Should you require any assistance with the safe and effective sealing of cables and pipe systems to ensure DSEAR | ATEX Regulatory Compliance please do not hesitate to contact Thorne & Derrick.

Duct Seals | Watertight | Gastight | Fire Resistant | Resist Rodents | Cables LV MV HV

Thorne & Derrick are Specialist Distributors to the Process Industries – we supply and support businesses working on the design, construction and maintenance of UK, European and international projects.

We can competently specify and competitively supply an extensive range of Hazardous Area Equipment (ATEX & IECEx) to provide Power, Heating & Lighting to the Explosive Atmospheres industries – this includes LV HV Cables, Accessories Jointing, Substation & Electrical Eqpt from 600V to 132kV.

Based in the UK, we are highly customer responsive and absolutely committed to providing a world-class service.

Since 1985, we have provided expert technical support and express delivery from extensive UK stocks to world-wide destinations.