Electrical Workforce | Are There Problems In The UK Electrical Industry?

Published 08 Jan 2020

The Electrical Workforce Ratio Guidance And Composition

-

Republished with the kind permission of Derek Thompson from Electrical Training Trust

SparkSafe Ltp has emerged from the Electrical Training Trust.

Established in 1998 by employers, Electrical Training Trust has championed the development of employer-Led Level 3 electrical apprenticeship training and adult worker upskilling.

Electrical Workforce Composition

We analysed eleven recent UK Public Sector construction projects with a combined value of circa £200 million to ascertain the composition of the electrical workforce.

The projects ranged in value from £500K to £60 million. Each of the projects is considered to be complex in scope as they:

- require significant coordination and cooperation with others

- make use of industrial pattern materials and techniques

- have an impact on the public

- involve professional design services

- require compliance with exceptional standards

- require a high-level health and safety management

SparkSafe workforce ratio guidance recommends a 50% minimum cohort of Qualified Electricians (QE) where complex electrical work is to be undertaken. None of the projects in the sample meets the proposed recommendations. Eight of the eleven projects are reported with a QE worker percentage between nil and 25%.

Summary of electrical work

- Three projects operated without a QE worker

- Four projects operated with a QE cohort of 15% or less

- One project (circa £30 million) relied on a 47% cohort of Apprentice Electrician (AE)

- The most significant value project (circa £60 million) was contingent on 75% of the electrical workforce operating below a QE licence level

Quality improvement and control measures are likely to be undermined when the model becomes over-reliant on disproportionate use of semi-skilled, under-qualified, or apprentice workers to carry complex and skilled tasks. Exceptions do exist. High-quality, close supervision, and other control measures may off-set the accumulation of defective work, reoccurring snagging lists, and latent defects. However, the trend, if unchecked, in this and other building service sectors, will continue to wither, an already ailing construction industry.

Historical toleration of this model has progressively shifted the Client prerogative to one of necessity and acceptance in terms of workforce composition in parts of the UK. Skilled labour shortages, lack of CPD drivers, and other demographic factors point to an industry that presently struggles to field a match fit team for industrial and commercial projects.

Extended supply chains and health and safety checks at the gate, have blurred Client insight into the occupational identity and qualitative make-up of the contractor’s workforce.

Nevertheless, projects are completed, commissioned, and eventually handed over.

So, what are the problems?

- A decline in quality and standards is widely reported throughout the industry. Clients are often forced to contend or accept failing and inconsistent standards by the industry to gain timely possession of their project.

- Failure to correct the problem means that it will become worse. The virtuous loop of sustainable skill training is replaced by a vicious circle which depletes the industry with a feed of semi-skilled and under-qualified workers.

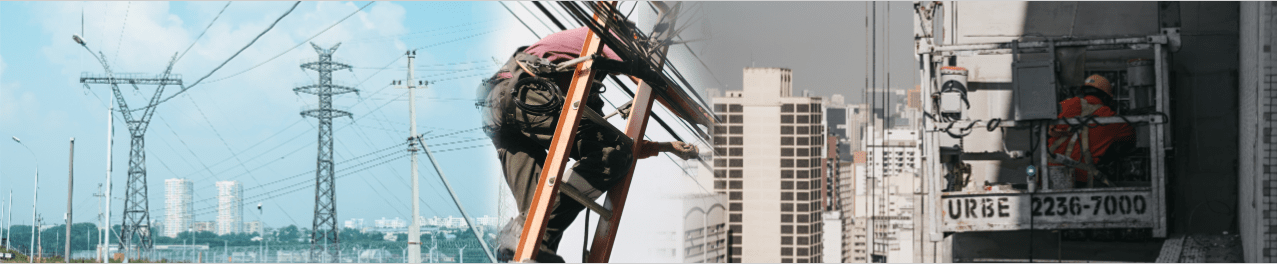

Photo : Electrical workers undertaking cable terminations by Hobi industri on Unsplash

Conclusion

The resolve of many responsible Electrical Contractors to maintain traditional standards has been eroded as other existing, and new enterprises adjust working practices to win contracts, build turnover and attempt to stay in business. Who could blame them! Discipline and restraint by the industry are poorly regulated. Insolvency and/or prosecution are the primary checks and balances for the UK electrical contracting industry.

Attempts at self-regulation have broken down as competitive instincts and market forces, compel the supply chain to find ways of getting around the national conventions of the industry. Industry-led, self-help efforts must continue. Responsible trade and industry bodies must be encouraged, supported and be subject to constructive criticism in their efforts to do the right thing. Nevertheless, the ultimate authority and influence over the behaviour and development of the industry is the Client.

The findings of our analysis flow from an absence of specification and scrutiny concerning the dynamics and composition of the contractor’s workforce ratio. A greater effort by specifiers and designers is usually placed on material specification. Whereas the competency of those who install those materials is often presumed and unchecked.

High spec materials and low-tech installers don’t make sense!

The striking imbalances across the sample projects are the immediate product of the industry, not the Client. However, by using their buying authority, responsible Clients can halt the decline, reinstate the virtuous loop, and help produce a much-needed win-win outcome for the UK going forward.

WORKFORCE RATIO GUIDANCE

Why was this developed?

Workforce ratio guidance aims to get the balance of manual electrical worker competencies right at site level. Client organisations and their professional representatives are often obliged to work on a trust basis regarding the flow and composition of an electrical contractor’s workforce. The issue of workforce composition and competency is often poorly defined or referenced in the specification and related documentation.

The number of “go-to” competent electrical workers in modern construction and maintenance contracts appears to have declined. Parts of the industry have become over dependant on under-qualified and unqualified electrical workers to meet tender budgets or overcome skills shortages. This shift means that the proportion of electrical competencies may not be matched to the requirements of the project.

We have produced the following ratio guidance as a quality improvement and social responsibility measure with the aim of stimulating productivity and performance. By including labour ratio competency requirements, specifiers will spur the industry towards sustainability in the construction industry.

Guidance on the Electrical Contractors Workforce Composition

Table 1 is aimed at addressing a typical complex multi-electrical service contract.

A Type Contract

| No. of Workers By Licence Type |

5 | 10 | 15 | 20 | 25 | 30 |

|---|---|---|---|---|---|---|

| QE | 2 | 5 | 7 | 10 | 12 | 15 |

| REW | 2 | 3 | 5 | 7 | 9 | 10 |

| AE | 1 | 2 | 3 | 3 | 4 | 5 |

We recommend that the electrical workforce should comprise of circa 50% Qualified Electricians (QE). A concession to make-up the balance of the required workforce by a mix and match approach from the Restricted and Apprentice Licence type should be made available. Note: A reasonable, contract-specific, pro-apprentice weighting should always be applied. We suggest that this should be not less than 20% of the required workforce.

Table 2 is offered in consideration of projects that are less complex regarding scope, value, coordination, risk and programme.

B Type Contract

| No. of Workers By Licence Type |

5 | 10 | 15 | 20 | 25 | 30 |

|---|---|---|---|---|---|---|

| QE | 2 | 3 | 5 | 6 | 8 | 9 |

| REW | 2 | 4 | 6 | 8 | 10 | 12 |

| AE | 1 | 3 | 4 | 6 | 7 | 9 |

This model indicates that circa one-third of the sub-contractors direct and indirect workforce should be fully qualified in line with the QE Licence type. A mix and match option similar to the A-Type concession is made available when it comes to determining the balance of the sub-contractors required workforce across the remaining Licence types.

Electrical EqUipment – Thorne & Derrick

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOGwith contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.