LS 220kV Cross Bonded Joint XLPE 2500sqmm Copper

Published 25 Nov 2020

Meet Richie Rice

Competent Master Craftsman | EHV Jointer

Richie Rice has a wealth of experience in the EHV Cable Sector and is expert and advanced skilled working on XLPE, HVDC Light XLPE, Oil/Gas Filled Cable Systems from Jointing & Terminating to VLF/ Sheath Testing. Certified from some of Europe’s leading manufacturers of GIS/ODSE Terminations & Straight / Sectionalised / Cross Bonded Joints up to 275kV.

Competent & Certificated by leading manufacturers of Cold Applied, Heat Shrink, Taped Joints & Terminations MV HV.

Supervision of Cable Installations overseeing all aspects of Works & Commissioning are carried out to client’s specifications – working in the Offshore Renewable Industry on Export & Array Cabling including Jointing/Terminating & Testing on power systems up to 155kV. Trained and Certified for VLF Testing of High Voltage Cables (XLPE) up to 120kV.

Contact [email protected] | or Connect via LinkedIn.

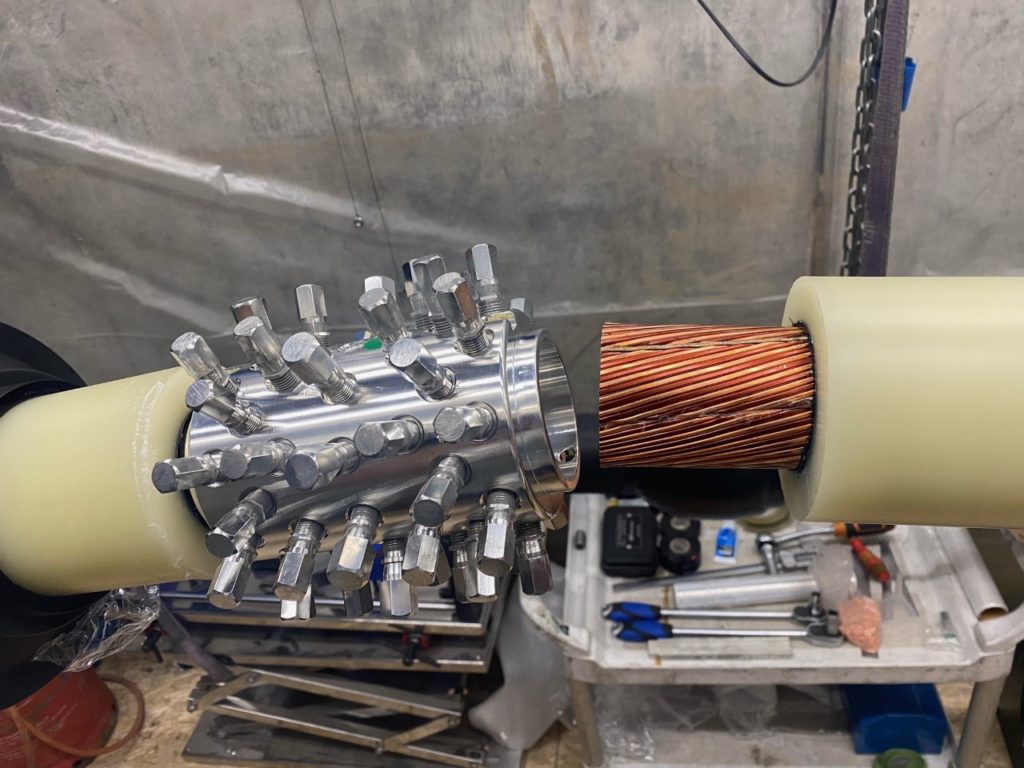

Technical Jointing Note: The paper beddings are not remove from the inner segment of the cable conductor – LS use copper particles between the cores compressed by 10no shear bolts that transfers current through these particles and this is why papers are not removed as is standard process where connectors are used for current transfer. This copper particle technique saves the cable jointer from opening cores and removing papers and the water blocking tapes – this is a significant benefit especially on Milliken Conductors.

LS Cable & Systems

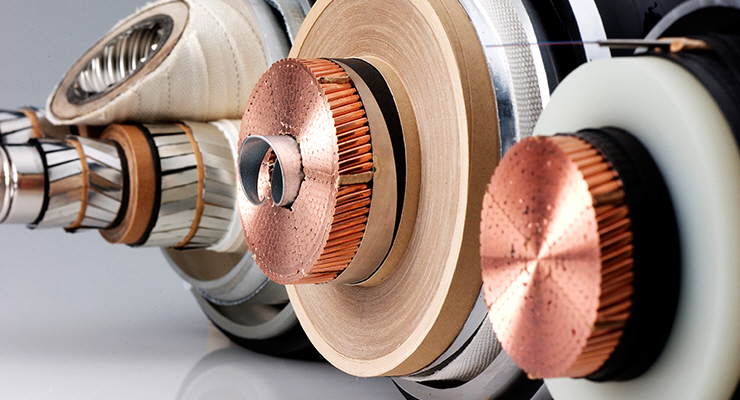

Extra-high voltage cables require the power network to go underground due to continuous increase of energy demand, larger transmission capacity, reliability of energy supply, safety and aesthetic issues. Among these cables, XLPE insulation cables are used widely due to their ease of handling, simpler jointing connectivity and maintenance, outstanding electrical features and other benefits.

XLPE Cables

The basic material for XLPE is polyethylene, which is chemically transformed to cross-linked polyethylene (XLPE) through the cross-link reaction of organic peroxides. The cross-link method for polyethylene was developed in the United States during the 1950’s and has since been continuously developed for application to higher voltage cables. Higher voltages are increasingly being required and now 500kV XLPE cables have already been commercialized by LS Cables.

Thorne & Derrick

Joints & Terminations

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV