Lovink

Lovink

CABLE JOINTS

Lovink is a global leader in medium- and high-voltage (MV / HV) cable jointing technologies, delivering industry-proven cable connection solutions for utilities, transmission networks, renewable energy, industrial and infrastructure projects. The Lovink product ranges such as LoviX and LoviSil emphasise high performance, long-term reliability, simplified installation and full lifecycle support.

Thorne & Derrick are the UK Authorised Distributor for Lovink Enertech and provide stock supply, technical support, project specification assistance, and global export logistics for Lovink’s cable jointing solutions.

Lovink Cable Joints

11kV 33kV

Lovink cable joints are engineered to provide safe, reliable, and long-lasting connections in medium-voltage power networks – typical operating voltages are 11kV and 33kV underground power cable networks. Designed for both polymeric (XLPE, EPR, HPTE) and paper-insulated cables (PILC), the cable joints accommodate a wide range of conductor sizes and cable diameters, making them versatile for diverse, harsh and hazardous applications.

Lovink Cable Joint Applications

- UK DNO Compliance (G81) & Contestable Connections (including NGED)

- High Water Table, Submersible, Seawater Resistant & Flood Zone Installations

- Mechanical Protection for Heavy Industrial Applications

- Asset Life Extension of Legacy Paper-Insulated Cables (PILC / PICAS)

- High Harmonics & Non-Linear Loads (Sags & Swells)

- Sine-Wave Distortion & Power Quality Improvement

- Abnormal Thermal Cycling in “High-Load / Low-Load” Systems

- Flame-Free Installation for Potentially Explosive Atmospheres

Lovix straight cable joints

Lovix straight cable joints

The Lovink LoviX R range provides a fast, reliable, and maintenance-free jointing solution for polymeric insulated cables. Designed for simplicity and safety, the LoviX system uses an innovative resin insulation to create a robust joint body offering excellent dielectric strength and moisture protection.

Features: Compact, factory-tested cold-shrink joints with excellent mechanical and electrical performance.

Applications: Joints suitable for medium-voltage cable connections in dry or standard environments.

Construction: Pre-expanded silicone body on a removable core for quick, tool-free installation.

Standards: Rated for 6kV–36kV cable systems; tested to international utility standards.

Customisation: Available for straight and transition joints in various cable types.

Maximum Cable Dimensions – Lovink LoviX Cable Joints

| Type | MV HV Cable Type | Conductor Size (mm²) | Insulation Diameter (mm) | Sheath Diameter (mm) |

|---|---|---|---|---|

| R50 | Polymeric XLPE / EPR / HPTE (1-core) | 95 – 240 | 19 – 32 | 24 – 50 |

| R60 | Polymeric XLPE / EPR / HPTE (1-core) | 185 – 400 | 30 – 42 | Max. 60 |

| R60 | Polymeric XLPE / EPR / HPTE (1-core) | 400 – 630 | 30 – 42 | Max. 60 |

| R70* | Polymeric XLPE / EPR / HPTE (1-core) | 400 – 630 | 35 – 54 | Max. 70 |

| R70* | Polymeric XLPE / EPR / HPTE (1-core) | 800 – 1000 | 35 – 54 | Max. 70 |

Lovisil straight through cable joints

The Lovink LoviSil system uses liquid silicone technology to ensure total encapsulation of cable connections. Its self-healing insulation properties and environmental resilience make it a preferred choice for critical infrastructure.

The LoviSil range is based on Lovink’s liquid silicone insulation technology, providing a self-healing, reusable, and environmentally resilient insulation system. Unlike conventional cold-shrink or resin systems, LoviSil joints are filled with a unique silicone liquid that permanently surrounds the cable connection.

LoviSil ideal for installations in wet, flood-prone, or corrosive environments, such as renewable energy connections, coastal networks, and utilities with strict reliability standards.

Features: Compact, factory-tested cold-shrink joint with excellent mechanical and electrical performance.

Applications: Suitable for medium-voltage cable connections in dry or standard environments.

Construction: Pre-expanded silicone body on a removable core for quick, tool-free installation.

Standards: Joints rated for 6–36 kV cable systems; tested to international utility standards.

Customisation: Available for straight and transition joints in various cable types.

Maximum Cable Joints Dimensions

Read more…

| Voltage Type | MV HV Cable | Conductor Size (mm²) | Diameter Conductor (mm) | Max. Cross Section for Crossed Conductors (mm²) | Max. Cross Section for Crossed Cores (mm) |

|---|---|---|---|---|---|

| M75 | Polymeric/paper (1 core) | 95 – 630 | N/A | N/A | 72 |

| M75 | Polymeric/paper (3 x 1 core) | 35 – 150 | N/A | N/A | 33 |

| M75 | Polymeric/paper (3 core) | 35 – 150 | 35 – 120 | 35 – 120 | 72 |

| M85 | Polymeric/paper (1 core) | 800 – 1000 | N/A | N/A | 82 |

| M85 | Polymeric/paper (3 x 1 core) | 95 – 240 | N/A | N/A | 38 |

| M85 | Plastic/paper (3 core) | 95 – 240 | 95 – 185 | 95 – 185 | 82 |

| M105 | Polymeric/paper (1 core) | 800 – 1000 | N/A | N/A | 105 |

| M105 | Polymeric/paper (3 x 1 core) | 95 – 400 | N/A | N/A | 48 |

| M105 | Polymeric/paper (3 core) | 95 – 400 | 300 | 300 | 105 |

| MK125 | Polymeric/paper (3 x 1 core) | 95 – 800 | N/A | N/A | 58 |

| MK125 | Plastic/paper (3 core) | 95 – 500 | N/A | N/A | 120 |

| M85 | Polymeric/paper (1 core) | 70 – 500 | N/A | N/A | 82 |

| M105 | Polymeric/paper (1 core) | 630 – 1000 | N/A | N/A | 105 |

| MK125 | Polymeric/paper (3 x 1 core) | 70 – 500 | N/A | N/A | 58 |

| MK125 | Polymeric/paper (3 core) | 70 – 500 | N/A | N/A | 120 |

Lovink Lovisil Transition Joints

Lovink Lovisil Transition Joints

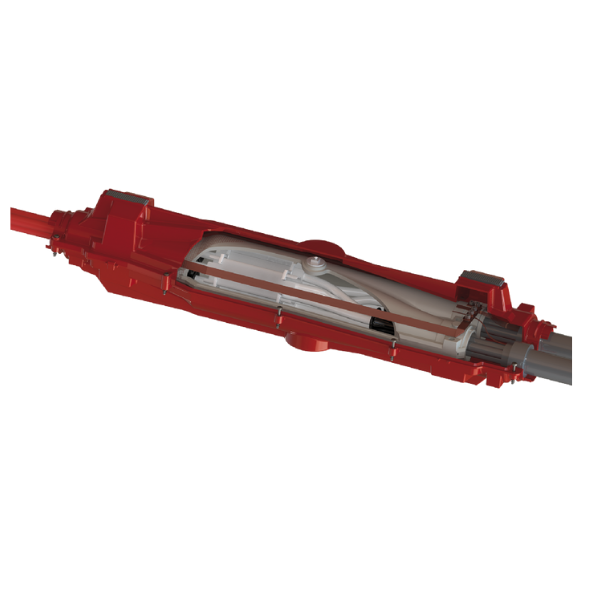

Lovink’s Lovisil Transition Joints are engineered for connecting different cable types — for example XLPE to PILC, or EPR to PVC — ensuring a safe, fully sealed and electrically balanced joint.

This system combines Lovink’s liquid silicone insulation with tailored internal stress control to accommodate varying conductor and insulation geometries. The result is a universal transition jointing solution suitable for network refurbishment, upgrade and repair projects.

Features: Factory-tested liquid silicone joint for reliable connection of dissimilar cable types with excellent electrical and mechanical performance.

Applications: Suitable for MV network upgrades and refurbishment connecting PILC to XLPE or EPR cables.

Construction: Transparent two-part shell filled with Lovink Lovisil® liquid silicone; includes stress control and moisture sealing components.

Standards: Joints Type-tested to CENELEC HD 629.1 S2 / IEC 60502-4 up to 42kV.

Customisation: Cable joints available for multiple cable sizes, insulation types and armoured or unarmoured configurations.

| Voltage | Lovink Joint Type | MV HV Cable | Conductor Size (mm²) | Diameter Conductor Crossed Conductors (mm²) | Max. Cross Section for Crossed Cores (mm) |

|---|---|---|---|---|---|

| 12 kV | M75 | Polymeric/paper (1 core) | 95 – 630 | N/A | 72 |

| M75 | Polymeric/paper (3 x 1 core) | 35 – 150 | N/A | 33 | |

| M75 | Polymeric/paper (3 core) | 35 – 150 | 35 – 120 | 72 | |

| M85 | Polymeric/paper (1 core) | 800 – 1.000 | N/A | 82 | |

| M85 | Polymeric/paper (3 x 1 core) | 95 – 240 | N/A | 38 | |

| M85 | Plastic/paper (3 core) | 95 – 240 | 95 – 185 | 82 | |

| M105 | Polymeric/paper (1 core) | 800 – 1.000 | N/A | 105 | |

| M105 | Polymeric/paper (3 x 1 core) | 95 – 400 | N/A | 48 | |

| M105 | Polymeric/paper (3 core) | 95 – 400 | 300 | 105 | |

| MK125 | Polymeric/paper (3 x 1 core) | 95 – 800 | N/A | 58 | |

| MK125 | Kunststof/papier (3 core) | 95 – 500 | N/A | 120 | |

| 24 kV | M75 | Polymeric/paper (1 core) | 95 – 240 | 72 | |

| M85 | Polymeric/paper (1 core) | 300 – 630 | N/A | 82 | |

| M85 | Polymeric/paper (3 x 1 core) | 95 – 150 | N/A | 38 | |

| M85 | Polymeric/paper (3 core) | 95 – 150 | 95 – 150 | 82 | |

| M105 | Polymeric/paper (1 core) | 800 – 1.000 | N/A | 105 | |

| M105 | Polymeric/paper (3 x 1 core) | 95 – 400 | N/A | 48 | |

| M105 | Polymeric/paper (3 core) | 95 – 400 | 240 | 105 | |

| MK125 | Polymeric/paper (3 x 1 core) | 95 – 800 | N/A | 58 | |

| MK125 | Polymeric/paper (3 core) | 95 – 500 | N/A | 120 | |

| 36 kV | M85 | Polymeric/paper (1 core) | 70 – 500 | 82 | |

| M105 | Polymeric/paper (1 core) | 630 – 1.000 | 105 | ||

| MK125 | Polymeric/paper (3 x 1 core) | 70 – 500 | N/A | 58 | |

| MK125 | Polymeric/paper (3 core) | 70 – 500 | N/A | 120 |

Additional Lovisil Cable Jointing Solutions

Below is an extended range of Lovisil joints engineered for network maintenance, upgrades, and cable repairs. Each system utilises Lovink’s liquid silicone insulation, ensuring complete encapsulation and reliable performance in challenging environments.

Lovisil Branch Joints

Lovisil Branch Joints

Lovisil Joints are designed for tapping into or splitting existing underground MV cable routes without compromising network reliability. The Lovisil cable jointing compound ensures a full moisture-resistant seal, suitable for buried and flooded environments.

Applications: Network expansion, connection of distributed generation, and sectional branching.

Construction: Two-part transparent shell filled with Lovisil® fluid and integrated stress control components.

Voltage Range: MV HV 6kV–36kV (11kV 33kV)

Lovisil Cable Repair Joints

Lovisil Cable Repair Joints

Lovisil Joints are used to restore damaged cable insulation and armour layers without requiring full cable replacement. Particularly valuable for emergency field repairs and maintaining grid reliability on medium and high voltage (MV HV) power cable systems.

Applications: Localised damage, sheath cuts, cable jacket repairs.

Construction: Protective outer shell sealed and filled with Lovisil liquid silicone.

Voltage Range: MV HV 6kV–36kV (11kV 33kV)

Lovisil Extended Joints

Lovisil Extended Joints

Lovisil joints are designed to join cables where additional shielding length, phase separation or thermal allowance is required. Ideal for installations in ducts or congested trenches.

Applications: Extra length required for installation tolerance, staged network refurbishment.

Construction: Extended transparent shell body filled fully with Lovisil® fluid.

Voltage Range: MV HV 6kV–36kV (11kV 33kV)

Lovisil Feed-In Joints

Lovisil Feed-In Joints

Lovisil joints are used to feed LV or MV cables into switchgear, transformers, cabinet terminations or grid connection points while retaining water-blocking integrity.

Applications: Renewable energy farms, substations, street networks.

Construction: Sealed transparent body with Lovisil fluid for moisture barrier.

Voltage Range: MV HV 6kV–36kV (11kV 33kV)

Lovisil Oil Refill Joints

Lovisil Oil Refill Joints

For legacy paper-insulated (PILC) cable systems where hydraulic oil pressure must be maintained. Used widely in older distribution and metropolitan networks at MV HV up to 36kV.

Applications: PILC network maintenance, network extensions.

Construction: Oil-compression sealed design with Lovisil insulation filling.

Voltage Range: MV HV 6kV–36kV (11kV 33kV)

Technical Selection Overview – Lovisil Network Jointing Solutions

| Lovink Product Type | Jointing Application | Cable Compatibility | HV Voltage Range | Key Advantage |

|---|---|---|---|---|

| Lovisil Branch Joints | Network branching / tee connections | Polymeric & PILC | 6–36 kV | Fully sealed liquid silicone insulated branch connection joint |

| Lovisil Repair Joint | Localised sheath / insulation repair | Polymeric & PILC | 6–36 kV | Restores cable integrity without replacing cable |

| Lovisil Extended Joint | Extra joint length for installation tolerance | Polymeric & PILC | 6–36 kV | Allows easier installation of the cable joint in confined route conditions |

| Lovisil Feed-in Joint | Cable entry to switchgear / cabinets / substations | Polymeric | 6–36 kV | Maintains moisture barrier at equipment termination |

| Lovisil Oil Refill Joint | PILC oil pressure maintained jointing | PILC / Transition | 6–36 kV | Compatible with oil-filled legacy networks |

Trusted Cable Jointing Technology

Lovink Enertech products are proven in service worldwide for network resilience, ease of installation, and long-term reliability.

Thorne & Derrick provide expert technical support, fast delivery and comprehensive stock availability for the complete Lovink range — from medium voltage straight joints to high voltage transition solutions.