Whitepaper | Roxtec Multi-Cable Transit Devices

Published 13 Oct 2020

Abstract

This is an introduction to applications and an engineering design approach for the proper use of Roxtec multi-cable transit devices within onshore oil, gas and petrochemical facilities. This paper demonstrates improved safety and improved project delivery when cable transit devices are included into owner and EPC design scopes.

International standards for cable transit devices and common safety demands are presented, including the use of Roxtec cable transit devices for vapor-tight barriers, blast-rated structures, fire walls, pressurized buildings, and simple ingress protection against environmental elements.

Incorporating Roxtec transits into owner-level and engineering-level design standards, is demonstrated to provide project savings that include reducing contractor work-hours, detail design time, and reduced field maintenance time. Proper multi-cable transit design and installations are also shown to increase project safety and operational uptime.

Introduction

- Components and Assembly Overview For Multi-Cable Transit Devices

- Applications For Roxtec Cable Transit Devices In Onshore Facilities

- Work Process & Design Approach For Roxtec Devices

- Details Required For Proper Specification Of Roxtec Devices

Hazardous Areas & Explosive Atmospheres (Gas & Dust) | Ex e and Ex tb Explosion Protection Certified by ATEX & IECEx | Zone 1/21 & Zone 2/22

Conclusion

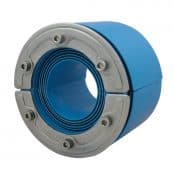

Roxtec modular cable transit seals are based upon a rubber design with seals that are constructed of a number of removable layers to secure a watertight, gas tight and fire proof seal around the cable or pipe – the range includes rectangular transits and round transits to fit a variety of pipes and cable sizes.

Process Industry

Typical Applications

Buildings & E-houses

Wall entries

Floor entries

Underground entries

Control rooms

Analyzer shelters

Substations

Remote instrument buildings (RIB)

Field auxiliary rooms (FAR)

Local equipment rooms (LER)

Terminal Boxes, Cabinets & Enclosures

Remote I/O cabinets

Hazardous locations (Ex e)

Ordinary locations

Electric heat tracing systems

Automation and control cabinets

DCS panels

Motor control cabinets

Safety instrumented systems (SIS)

Fire and gas detection control cabinets

Machine monitoring systems

Lighting panels

Thorne & Derrick are distributors for Roxtec, the leading manufacturer of sealing solutions for cables and pipes, – protecting cables and pipes in the process industry sector against water, gas and fire.

Further Reading

Sealing Pipes & Cables in the Hazardous Area & Process Industries Using Roxtec

- Whitepaper: EMP/EMI Protection In Control Rooms/Centres In Critical Infrastructure

- Whitepaper: Modular Integration of Process Equipment Packages for Oil and Gas Facilities

- Whitepaper | Modular Cable Termination Design By Roxtec

CONTACT US WITH YOUR ENQUIRY

Specialist Distributors of Industrial & Hazardous Area Equipment to provide Power, Heat, Light & Ventilation to the explosive atmospheres and process industries.

Control Panels | Plugs | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Ventilation Fans | Security Access Control

Competitive Prices | Extensive Stocks | Technical Support | Express Delivery