DENSOBAND | Sealing Joints In Highway Construction & Maintenance

Published 08 Mar 2021

Highway Joint Sealing

Densoband

Densoband™ is a polymer modified bitumen compound in strip form, used for sealing joints between asphalt to asphalt, concrete and road castings in road construction and bridge expansion joints. It can also be used for airport runway joints and light railway/tram construction to form a flexible seal between the track and the surrounding asphalt.

Containing filler, a flow control additive and a root deterrent, Densoband forms a flexible watertight seal which allows for road movement from cyclic traffic load and thermal changes to prevent cracking and subsequent erosion.

Providing a uniform flexible seal across the joint face, Densoband™ is ideal for base and wearing course joints and prevents deterioration by sealing out water, chemical pollutants, weed seeds and other pollutants/contaminants.

When applying Densoband with a gas torch, a uniform, consistent joint is recommended rather than a randomly poured joint.

➡ See also Denso Mastic Duct Seal | Densoseal 16A Sealing Cable Ducts

Densoband Features

- Used in road, tramway, railway and airport runway repair and construction

- Sealing bridge and flyover expansion joints

- Minimises return maintenance visits

- Uniform flexible seal for base and wearing course joints

- Adheres to asphalt, concrete and ironware

- Withstands road movement from traffic load and thermal changes

- Over 25-years use in the UK

- Densoband fully complies with the Department of Transport Specification for Highway Works, 7th Edition

Instructions For Use

Joint Surface

The joint surface should be sawn for preference to present an even vertical face throughout its length.

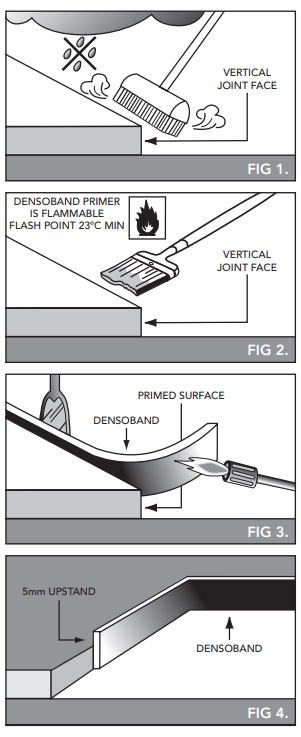

Cleaning (see Fig 1.)

Do not apply Densoband to wet or oil contaminated surfaces.

- Ashpalt, concrete, kerbstone surfaces: Clean with a stiff broom or wire brush to remove all dust, dirt, debris

- Metal surfaces such as road castings: Wire brush to remove all loose rust, dirt, etc.

Priming (see Fig 2.)

Apply Densoband™ Primer to the vertical joint face and allow to dry.

Applying Densoband (see Figs 3 & 4)

- Cut Densoband to length.

- Remove interleaving paper.

- Heat one surface of the Densoband with a gas torch.

- Apply the molten surface to the primed face using the applicator spatula or similar tool to assist adhesion. Densoband should stand 5mm proud of the existing road surface. Trim flush to metal.

- Mitre Densoband into corners of right angle joints.

Compaction

After laying and levelling the new wearing course asphalt, the first pass of the roller should be along the joint edges, compacting the Densoband to form a ‘rivet head’.

Further Reading

Sealing & Waterproofing of Cable Ducts Using Densoseal 16A | Thames Water Project

Denso Mastic Duct Seal | Densoseal 16A Sealing Cable Ducts

Denso Bore-Wrap | Prevent Coating Damage During Pipeline Installations

About Denso

Denso North America Inc. is a subsidiary of Winn & Coales International, a leading manufacturer of anti-corrosion coatings that include Protal liquid epoxies, Denso petrolatum tapes, mastics, primers, bitumen tapes, butyl tapes, hot applied tapes, and a full line of marine pile protection systems. Winn & Coales was originally established as a business in London, England, in 1883, and the first petrolatum tape manufactured in the UK was Denso tape, manufactured under license by Winn & Coales (Denso) Limited.

Denso tape was developed over 80 years ago for the “Long Life Protection” of buried steel pipelines against corrosion. The Denso SeaShield Marine Systems include fiberglass forms, epoxy grouts, underwater epoxies, injectable epoxies, petrolatum tape and wrap systems.

Thorne & Derrick are Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV