Unlocking The Power Of Solar | Electrical Balance of System in Solar Applications

Published 19 Mar 2024

Unlocking The Power Of Solar | Electrical Balance of System in Solar Applications

The hard parts are done. You have a solar farm site ready to build and an order placed for high performance PV modules, best-in-class inverters, and a tracking system to maximise energy production. Now you just need to figure out how to get it all connected.

Easy, right?

It’s not rocket science, but thoughtful selection of Electrical Balance of System (EBOS) components is essential for project success. In a recent audit from Solargrade, 62% of all utility-scale solar projects had critical safety issues, 91% of which related to direct current (DC) power distribution. Most issues were caused by field-made connectors and wire management, components of the EBOS.

To understand where to focus to create a reliable, high-performance EBOS, let us start with the PV module and work our way to the DC/AC inverters that connect to the grid.

➡ Thorne & Derrick partner with Panduit to bring the most innovative renewable energies solutions to the market.

Below discover how Panduit is at the forefront of accelerating solar projects, enhancing reliability, and increasing profitability with our expert insights on navigating Electrical Balance of System (EBOS).

Join us as we unlock the potential of solar energy for reliable, efficient projects.

Electrical Balance of System Components IN THE SOLAR iNDUSTRY

PV modules range in size and power output, but all have DC wires exiting from a junction box on the back. In a solar array, these wires are routed as a bundle or spliced together at prescribed intervals and fed into a combiner box. The combiner box, as its name suggests, combines the power from these strings of modules so that a pair of larger, high-voltage cables can carry their combined power in a “home run” to the inverter and then eventually on to the grid.

Commercial and utility scale solar projects necessarily have a large footprint to produce the amount of required power. Because each PV module only creates 400–600 W, you need 1,667–2,500 modules to produce just one megawatt (MW) of electricity, and utility projects can typically range anywhere from 20 to 500+ MW. With all that scale comes a huge amount of cable to manage. And because these projects are placed in areas with intense sun, all the components are exposed to the elements. To be reliable, solar cable management solutions must securely hold cables in high wind, protect from long-term abrasion, withstand harsh UV, potential chemical exposure, and extreme temperatures.

Several suitable options exist for routing smaller cables along the back of PV modules. The most common include dedicated solar clips that snap on the metal frame, specialised wire hangers that fit through holes in the frame, and heavy-duty cable ties. Arrays that move to track the sun create some additional challenges with abrasion, so flexible corrugated tubing is often used to surround cables and protect around potential pinch points.

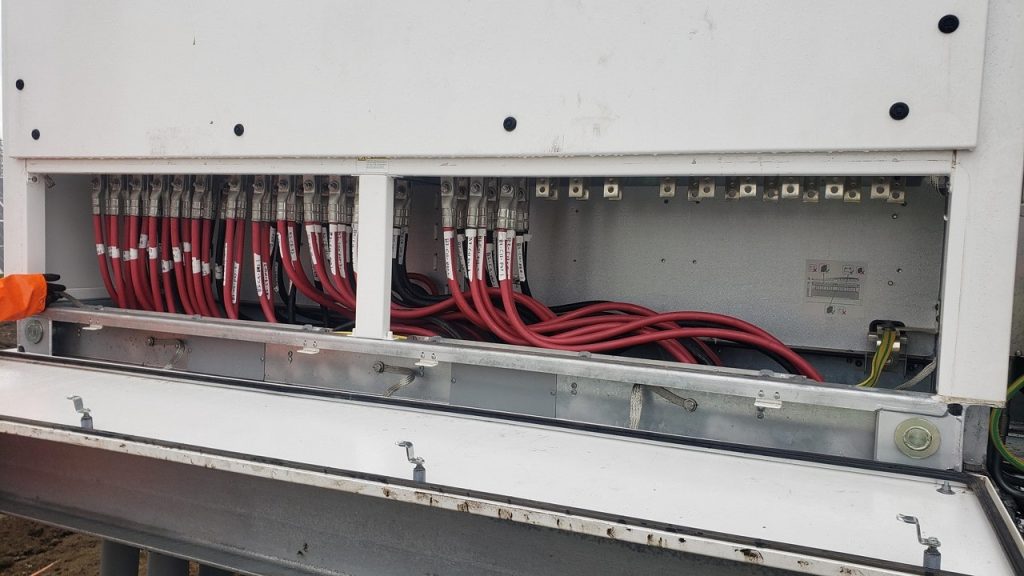

At each combiner box, dozens of smaller cables enter and connect to a pair of busbar conductors, most commonly with power lugs. The lugs are crimped using tools or mechanically terminated to the ends of the wires and secured to the busbar with screws to ensure reliability and efficiency.

Power exits the combiner box through higher-voltage cables and is routed one of two ways: either below ground in a trench or suspended in bundles from steel cables strung in-between rows. These higher voltage “home run” cables carry power to an inverter connected to the grid, or directly to DC battery storage on site.

As with any electrical system, proper bonding and grounding are critical parts of a solar project. Grounding provides a super-low-resistance path for electricity to flow, so that power can safely complete a circuit should a fault occur.

In the EBOS, bonding components like lugs and straps connect each of the individual array components together and then to the grounding system. Without proper grounding, tray and racking surfaces can become energised in the event of a fault, creating a life-threatening situation for people working on the solar array.

Most solar safety and reliability issues emerge from mistakes in managing DC wiring and grounding. Selecting appropriate cable management, termination, and grounding solutions can prevent some challenges. Placing an emphasis on ease of installation, quality materials, and long-term reliability when specifying EBOS components will minimise problems once the project is built.

Maximising Return on Investment Through EBOS

Like any utility, the goal of solar farms is to produce the most usable energy at the lowest total cost over the life of the project. To optimise long-term return on investment, it’s important to consider ease of installation, durability, and safety when selecting BOS components.

Finding skilled labour continues to be a challenge in the construction industry, and the labour needed to connect 2,500 PV modules is significant, let alone 2.5 million. EBOS solutions that simplify installation and minimise re-work can noticeably reduce labour hours and total installation costs. Even components that save seconds per operation compound to significant time savings over the duration of the build.

Once a power plant is commissioned, any downtime directly impacts profitability. Because these projects necessarily involve hundreds of thousands of individual modules, any weaknesses in components will be exposed and magnified. Selecting products specifically designed to last years in harsh environments reduces unplanned maintenance costs and lowers the total cost of ownership over the life of the project.

Solar projects typically have a usable lifespan of 25+ years. To maintain the highest level of production, it’s necessary to perform regular maintenance, which includes everything from cleaning modules and controlling vegetation to replacing deteriorating components.

Effective labelling of all system components during installation is critical for future operations personnel to interact with equipment safely and efficiently. Exposure to UV and precipitation can lead to fading and make labels illegible, so high-quality, easy-to-read solutions designed for outdoor environments are a good investment to ensure efficient maintenance in the future.

Summary

Though EBOS components (excluding wire) represent less than 5% of total project costs, they can be an important way to control costs and optimise performance throughout the life of a solar installation. Quality components maximise labour efficiency during the initial build and result in fewer errors that require re-work. Using longer lasting environment-specific materials and easy-to-read labelling solutions simplifies future operations and reduces maintenance costs. And most importantly, getting EBOS right addresses the most common critical safety issues found in solar projects today.

Sources: Solar Grade PV Health Report: The-Solar Grade PV-Health-Report_First-Edition.pdf

Andrew Hammond – Panduit

Experienced Brand Marketer with a specialization in strategy, content marketing, product marketing, storytelling, public relations, event management, athlete and ambassador partnerships, advertising, and team leadership.

Andrew is a member of the Panduit Renewable Energy team as a Product Marketing Manager. He is passionate about building an electrified future and the technology powering energy transformation.

Panduit Electrical Group is a world wide leader in the manufacture of high-quality electrical products including cable ties, wiring accessories, terminals, and identification products such as computer printable labels and portable labelling systems, wiring duct, heat shrink tubing, wire abrasion protection, and accessories.

Thorne & Derrick are Specialist Distributors to Solar EPC’s & High Voltage Jointing Contractors working on the design, construction and maintenance of UK, European and international projects supplying an extensive range of LV HV Solar Cables, Jointing, Substation & Electrical Eqpt. Based in the UK, we are highly customer responsive and absolutely committed to providing a world-class service.

We stock LV HV Solar Cables, Accessories & Electrical Equipment to enable the construction, maintenance and operation of utility-scale PV installations – our products connect 600V/1500V solar cables into combiner boxes, inverters, transformers and energise switchgear up to 33kV/132kV for high voltage grid connections.

Since 1985, we have provided expert technical support and express delivery from extensive UK stocks to world-wide destinations.

We look forward to working to with you on your next Solar project.