HV Cable Sheath Bonding Methods | High Voltage Power Systems

Published 10 Mar 2024

Joint | Terminate | Connect Medium & High Voltage Cables MV HV

MV HV High Voltage Cable Joints | Cable Terminations | Cable Connectors

Cable Sheath Bonding

Each HV cable sheath bonding method has its advantages and applications.

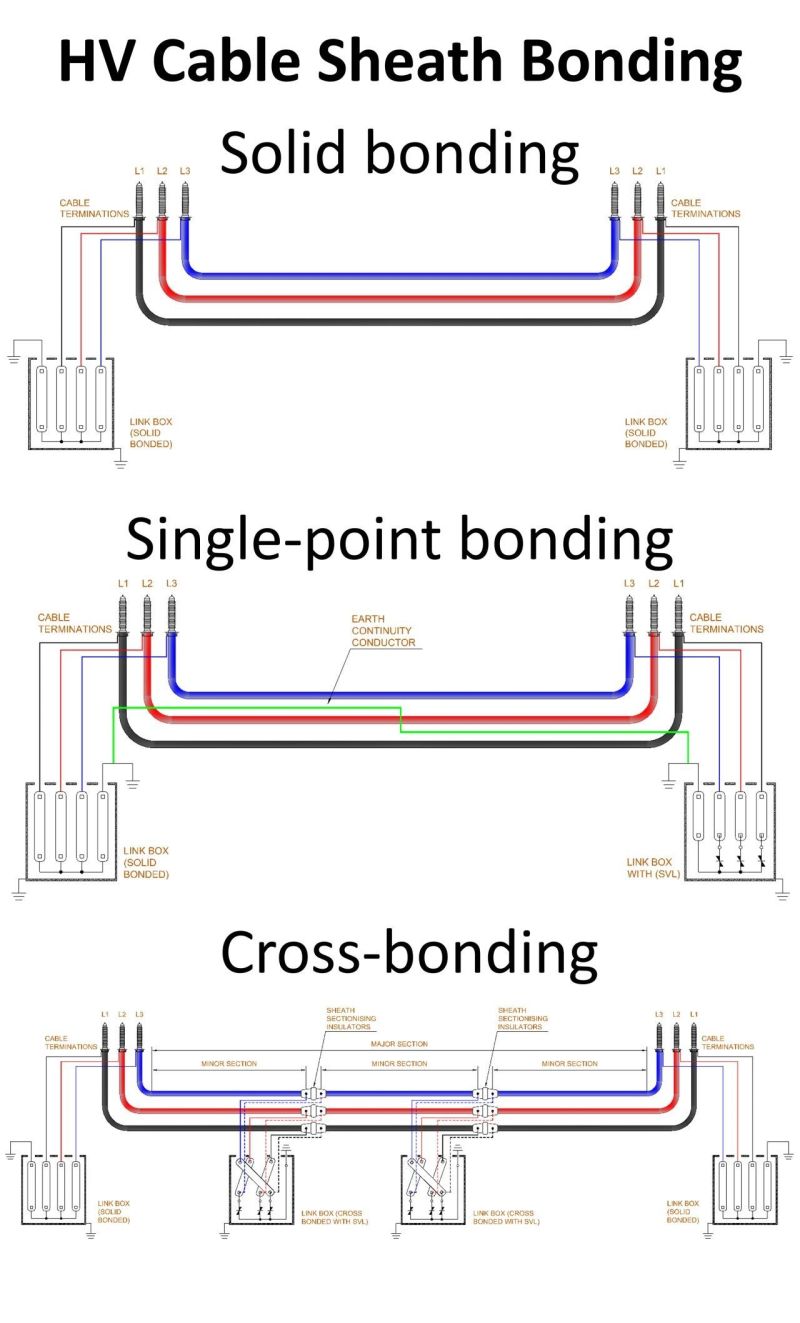

Solid bonding of high voltage cables is simple but leads to sheath losses, single-point bonding eliminates circulating currents but requires voltage control, and cross-bonding is the most efficient for long HV cables, minimizing losses.

The choice depends on High Voltage Power System requirements, cable length and operational efficiency.

Solid Bonding

In this method, the metallic sheath of the cable is bonded at both ends and connected to the earth. This results in continuous current flow in the sheath due to the induced voltage.

Solid Bonding Advantages: Simple to install.

Disadvantages: High circulating currents in the sheath lead to power losses and increased heating. Best suited for: Short high voltage cable routes where sheath current losses are minimal.

Single Point Bonding

The sheath is bonded to the earth at only one end, with the other end left open and insulated. An earth continuity conductor is used to maintain equipotential grounding.

This method eliminates circulating currents but results in induced sheath voltages, which can be high. To control this, sheath voltage limiters (SVL) are used.

Single Point Bonding Advantages: Reduces power losses as no sheath currents circulate.

Disadvantages: Requires careful management of sheath voltages. Best suited for: Medium-length high voltage cable systems.

Cross Bonding

The high voltage cable length is divided into three equal sections (minor sections) within a major section. At each section junction, the cable sheaths are cross-bonded using link boxes to balance out induced voltages. This technique cancels out circulating currents, reducing sheath losses significantly.

Cross Bonding Advantages: The most efficient method, significantly reducing losses.

Disadvantages: Complex installation and maintenance. Best suited for: Long-distance high voltage cable routes.

Thorne & Derrick Specialist Electrical Distributor

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Installation & Cable Pulling Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Sealing Cable Ducts, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment