Installing Heavy Duty Safety Nets From Cable Safe

Published 04 Oct 2023

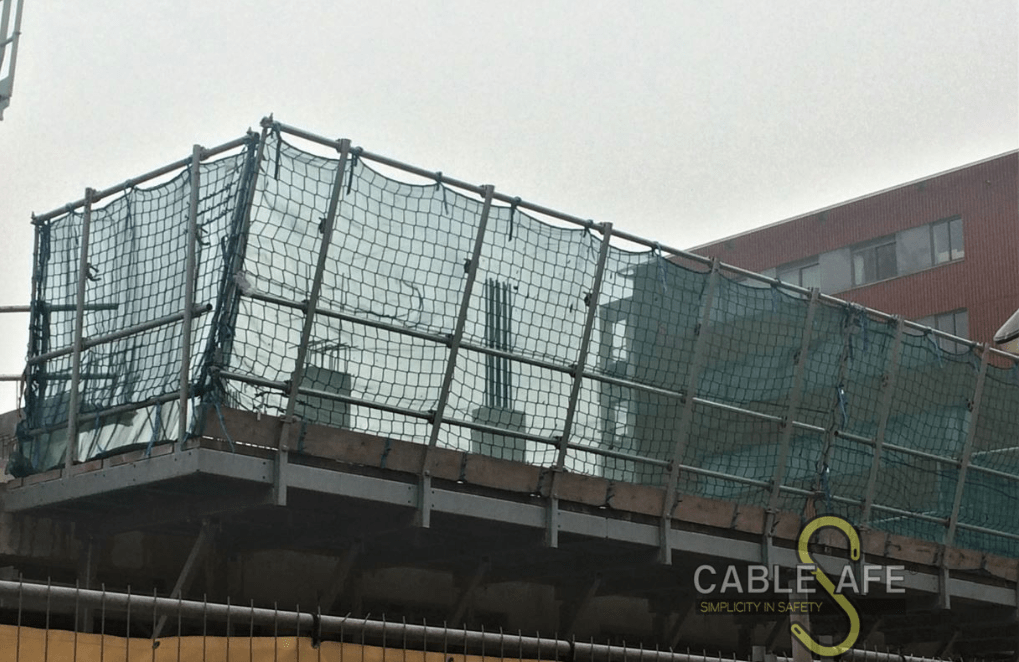

Heavy-Duty Safety Net From Cable Safe

Fall Protection Safety Net

Safety is paramount in the construction and industrial industry, and ensuring the well-being of workers and the protection of valuable equipment is a top priority.

Workplace safety refers to the measures put in place to prevent injuries, illnesses, accidents, and hazards in a work environment. These measures include equipment maintenance, employee training, safety protocols, emergency plans, and hazard identification and mitigation. Ensuring workplace safety is important for the well-being of employees, compliance with regulations and maintaining productivity. Employers have a legal and ethical obligation to provide a safe work environment for their employees and to take accountability for their well-being.

One essential component of workplace safety in these environments is the use of heavy-duty safety nets, particularly stainless steel secondary retention nets. In this blog we’ll explore types of safety nets, including rolls and fit-to-size solutions, and provide insights into their assembly along with industrial installation, safe use and the importance of a safety net for fall protection.

Stainless steel secondary retention safety nets are engineered to provide robust fall protection and containment, making them indispensable in industries where heavy machinery, tools, and materials are used. These nets are not only durable but also highly corrosion-resistant, making them ideal for long-term use in challenging environments.

➡ Thorne & Derrick supply the complete range of Safety Tools & Equipment from Cable Safe to enable safe working across all industries. This includes cable safety hooks, self-closing safety gates, confined space entry protection, guard nets and cable stands.

Assembly instructions

Correct assembly of fall protection nets is crucial for their effectiveness. Cable Safe provide detailed assembly instructions with all of their stainless steel safety nets to ensure that they are installed correctly. Following these instructions meticulously is essential to guarantee a secure fit and optimal protection.

Assembly involves precise measurements and installation techniques to create a reliable safety barrier. Stainless steel secondary retention safety nets can be custom-tailored to fit specific areas or come in standard roll formats. During assembly, it’s vital to account for factors like height, load-bearing capacity, and attachment points. Expertise in assembly ensures that the nets serve their intended purpose effectively.

Industrial Safety Net Installation

Personnel safety netting is designed to deflect and absorb the energy of a fall, to prevent injuries. As part of personnel safety and employee protection, safety net systems can be installed to high work areas to protect employees, nearby structures and pedestrians below

Installing industrial safety nets, especially in high-risk areas, demands skill and precision. To install the product correctly it involves inspecting anchor points, ensuring adequate tension, and verifying that the netting is securely fastened. When dealing with stainless steel secondary retention netting, which are known for their strength, the installation process requires high attention to detail. A construction safety net has to be as close under the surface on which employees are working, but never more than 30 feet below the surface.

Fall Protection Net Roll From Cable Safe

Ensuring the safe use of nets once installed is also vital. Workers should be trained in safety net protocols, including how to inspect the nets for damage, avoid overloading, and use proper personal protective equipment. Safety systems should be regularly inspected and maintained to identify and rectify any issues promptly.

Examples of Heavy Duty Safety Nets

- Safety Net Rolls: These versatile nets come in rolls, making them easy to transport and install. They are ideal for covering large areas quickly and effectively, offering reliable fall protection and containment.

- Safety Net Fit-to-size: custom-fit stainless steel nets are available in situations where precision is paramount. These nets are tailored to specific measurements, ensuring a perfect fit for any industrial setting. They provide maximum safety without compromising on aesthetics or functionality.

Stainless steel secondary retention nets play a crucial role in safeguarding workers and equipment in heavy-duty industries. Proper assembly, installation, and safe use are all important for full effectiveness. The addition of a safety catch net further enhances workplace safety.

CABLE SAFETY EQUIPMENT

CableSafe® Safety solutions are critical cable essentials and are well proven construction safety products. The CableSafe® range of cable hooks can be used during maintenance, turnaround, outages, shutdowns, construction work to suspend cables and hoses and other work gear and equipment from the working space.

Cable Safety Equipment | Cable Stand | Cable Bridge | Cable Rail | Cable Guard | Dropped Object Prevention Mats

PUSH PULL TOOLING

Thorne & Derrick stock and distribute a range of Safety Tools including Push Pull Tools from Hand Safety Tool Company designed to minimise hand injuries by keeping hands out of the line of fire.

Further Reading

-

CableSafe – Electrical Cable Safety LV MV HV

Size: 4.89 MB

CableSafe – Electrical Cable Safety LV MV HV

Size: 4.89 MB