Marconite – Electrically Conductive Earthing Compound

Published 14 Nov 2018

Marconite

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Low Resistance Earthing Compounds

for Substations

Marconite is developed and manufactured specifically for use in electrical earthing installations enabling electrical engineers and earthing system designers to achieve permanent, stable and low resistance earthing solutions even in difficult ground or soil conditions – typically used for substation earthing applications.

Adding Bentonite and similar earthing compounds, such as Marconite, in a trench or larger drilled hole around the electrode, typically an earth rod, has the effect of increasing the surface area of the earth conductor, assuming the resistivity of the added material is lower than that of the surrounding soil.

Earthing Compunds

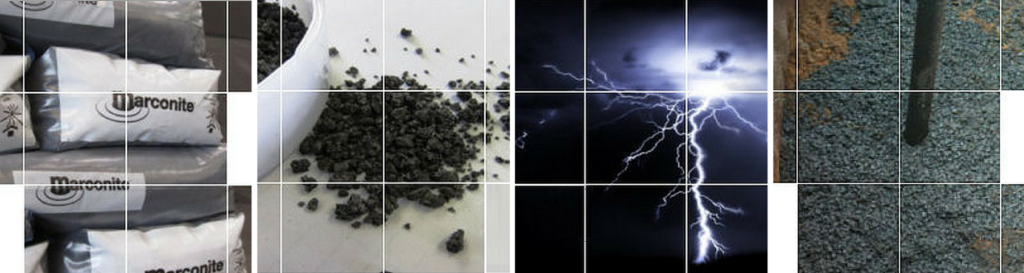

Marconite compound is a precisely measured, granular material, dark grey in colour, that is virtually dust free and with exceptional electrical properties.

| Marconite Earthing Compound Benefits | |

| Low Resistivity | 0.001 ohm.m is extremely low when compared to Bentonite’s 3 ohm.m |

| Versatile | Suitable for most ground conditions and becomes a permanent, solid structure that it is not prone to shrinking, drying out or being washed away |

| Cost Effective | It is a permanent solution; there is no need to remove and replace or ‘maintain’ it with additional water / salts every few years in order to achieve the desired earth values |

| Chemically Inert | Is non-corrosive to steel or copper, does not attack cement structures and has a pH within the neutral range |

| High Strength | Can be used as part of the building structure itself and can achieve strengths higher than Grade 25 concrete |

| Easy To Use | Forms a concrete like material that from first pour, achieves a low resistance earth, no need to wait or return to test |

More About Marconite

Marconite is essentially a conductive concrete in which a carbonaceous aggregate replaces the normal aggregate used in the conventional concrete mix – Marconite earthing compound has some similar properties to Bentonite, i.e. causes minimal corrosion with certain metals and has a low resistivity. It was developed as a process which started in 1962 when Marconi engineers sought a material which conducted by movement of electrons rather than ions. It contains a crystalline form of carbon and the overall material has a low sulphur and chloride content.

There is stated to be some corrosion of ferrous metal and copper whilst the Marconite is in slurry form, but it is suggested that a thin protective layer forms. When the concrete has set, corrosion is said to cease. Metal should ideally be painted with bitumen or a bitumastic paint as it enters the Marconite structure to prevent corrosion at this point. Aluminium, tin coated or galvanised steel should not be installed in Marconite.

When Marconite is mixed with concrete, its resistivity can fall to as low as 0.1 Ohm-metre. It will retain its moisture even under quite dry conditions so has been used in the hotter climates as an alternative to Bentonite compound. Its principle application in the UK is at locations where theft or third party interference is likely to be a problem, or to enclose copper electrodes in bore-holes or voids within rock when driven into the ground.

When surrounding an earth rod with Marconite which has been installed in rock, the resistance of the copper earth rod will be reduced as the volume of Marconite used is increased. For example, if a 1 metre earth rod is installed at the centre of a hemisphere of Marconite of radius 1.5m, it would have a resistance of approximately 2,000 Ohm if the surrounding rock is of 2,000 Ohm-metres.

Call T&D for Copper Earthing Tapes | Best Prices | Large Stocks

If the radius of the hemishere is increased to 3 metre and then 5 metre, the resistance would fall to 1,080 Ohm and 650 Ohm respectively. Because of the prohibitive cost of removing such a volume of rock, it makes sense to make use of existing cavities for this purpose, where possible. Also, the void is likely to be part filled with other materials (such as concrete) to reduce the amount of proprietary material required. Marconite is normally considered as having a resistivity of 2 Ohm-metres.

T&D provide fast delivery and competitive prices for genuine Marconite brand earthing compounds.

Marconite – Electrically Conductive Aggregate Material

SUBSTATION EARTHING & MV HV CABLE JOINTING

To complement Earthing & Lightning Protection & Exothermic Welding products we stock and distribute the most extensive range of copper earthing equipment.