Power Shunts 600amps Current Rating | 250sqmm Cross Section

Power Shunts 600amps – Flexible Copper Busbars & Braid Connectors

Power Shunts 600amps

Cost Effective Alternative to Power Cable & Solid Bus-bars

Power shunts are large cross-sectional area copper braided connectors, customised and designed to meet the increasing demands of LV MV HV power distribution applications including power stations, generators, switchgear and power transmission.

Power shunts are often designed with multi-layers of flat or round copper braids – this shunt with a cross section area of 250sqmm can conduct and distribute 600amps electrical current.

600amp power shunts are used as an alternative to solid bus-bars and power cable assemblies: power shunts are capable of carrying very high currents yet are flexible, robust, easy to install and cost effective.

Typical power shunt applications : power stations, transformers, motors, generators, switchgear, substations – low and high voltages (LV MV HV), high current carrying capacity copper braided connectors for flexible power distribution.

♦ See also | Earth Bonds | Earth Bosses

600amps Power Shunts – Large Earth Braid Connectors

BRAID & TERMINATION SELECTION

All power shunts can be customised designed to suit the electrical distribution requirement of the application – 600amp power shunts can be supplied with solid palms for drilling out holes to suit the transformer or switchgear busbar arrangement.

| Conductivity | Oxidisation Resistance |

Operating Temperature | |

| Plain Copper Braid | Good | Fair | Medium |

| Tin-plated Copper Braid | Good | Good | Medium |

| Nickel Plated Copper Braid | Good | Excellent | Good |

| Silver Plated Copper Braid | Excellent | Good | Good |

The actual current rating of a power shunt will vary accordingly to the design and layout of the final braid configuration. It is recommended that each power shunt be tested and evaluated fully to ascertain its suitability to meet the requirements of its final application.

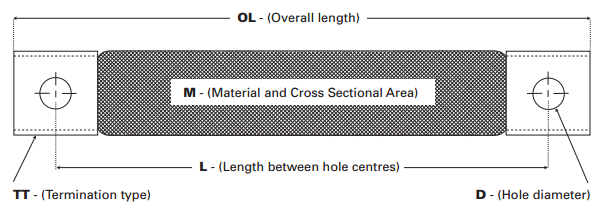

HOW TO ORDER POWER SHUNTS

Power Shunts

To enable the custom design and specification of Power Shunts to meet specific applications we require the following information

- OL – Overall Shunt Length

- L – Length Between Hole Centres

- D – Hole Diameter

- M – Shunt Material & Cross Sectional Area (CSA)

- TT – Shunt Termination Type

Ferrule Finishes

Power shunts are available pre-terminated using Ferrules (end plates) available with different plated finishes including; Tin, Nickel and Silver. When used in parallel (“back-toback”) the two power shunts must be spaced with a minimum distance equal to the thickness of the shunt to allow air cooling.

Flexible copper connector power shunts can be insulated using protective heat shrink sleeving for identification.