Load Break Elbow Probe Insertion Tool 15kV-34.5kV Elbows – Ripley PIT 1T

Load Break Elbow Probe Insertion Tool

Ripley PIT 1T

The Ripley PIT 1T is a load break elbow probe insertion tool for 15kV to 34.5kV elbows, allowing for quick and easy insertion of the probe inside the elbow.

Ripley PIT 1T tool prevents load break contamination & breakage and reduces cross threading and has a 125 in-lb torque delivery system.

Ripley PIT 1T Cable Tool

Specifications

- For 15kV-34.5kV elbow – small interface

- For quick and easy insertion of the probe inside the elbow

- Prevents load break probe contamination

- Prevents load break probe breakage

- Reduces cross threading

- Provides the proper tightening forces as recommended by the elbow manufacturers

- Multiple drive system:

– Delivers 125 in-lb torque

– Adjustable (Full “T” Handle or Moment arm for tight locations) and removable “T” handle

– 1 in. (25.4 mm) steel drive and adjustable wrench

– 3/8 in. (10 mm) square drive socket

– Standard ‘Penta’ Head - Load Break Probe quickly removed by simply reversing the tightening action

- Available for all load break elbows

- Made in the U.S.A.

- Length: 9.375 in (238.13 mm)

- Weight: 1 lb 4 oz (568 g)

- Part No.: 35150

- U.S. Patent No.: 5,605,082

- More: Cable Jointers Tools for LV-MV Cables & Equipment

| Model | Order Code | Compatibility | Torque | Length | Weight |

| PIT 1T | 35150 | All load break elbows | 125 in-lb | 9.375″ (238.1mm) | 1lb 4 oz (568g) |

Ripley PIT 1T cable tool – Operating Instructions

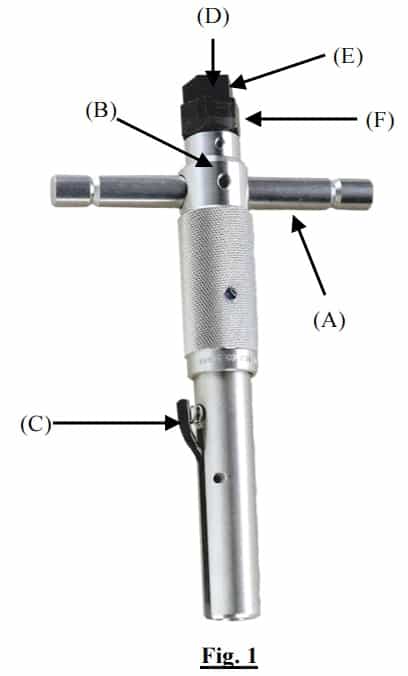

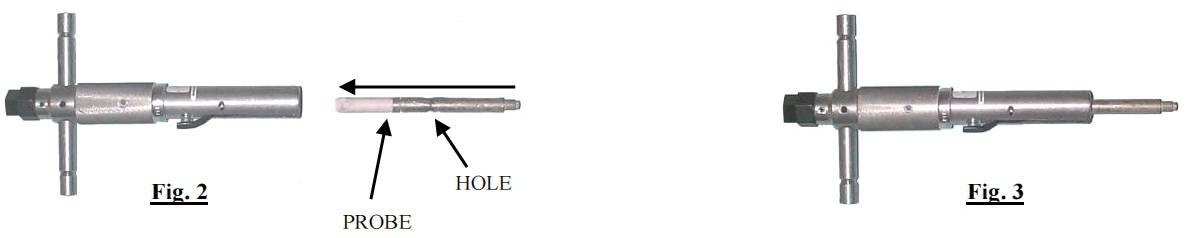

- 1. (Fig. 2) Assemble the T-Bar handle (A) into the tool body and secure by tightening screw (B).

- 2. Insert the probe into the tool by depressing the spring loaded lever (C), this will allow the probe to enter the tool cavity. Align the probe hole with the tool lever pin and insert the probe until the probe hole and pin are in alignment. Release the spring loaded lever (C) as in (Fig. 3). Be careful not to dirty or damage the arc-quenching material on the probe.

- 3. Holding the tool with the probe locked in place, insert the probe into the load break elbow and slowly rotate the tool clockwise to thread the probe into the crimp connector inside the elbow.

- 4. Continue to rotate the tool and tighten until the clutch ratcheting is felt. An audible snapping will be heard, along with the ratcheting of the tool. This will indicate the torque value of 125 in-lb has been reached.

- 5. Depress the spring loaded lever (C) and carefully remove the tool from the probe.

To remove the probe follow Steps 1-3; In Step 3, rotate counter-clockwise to unthread the probe.

For Additional Leverage

- The T-Bar handle can be repositioned by loosening screw (B) and sliding the T-Bar handle to the groove(s) provided.

- A 3/8” (9.53mm) drive opening (D) at the top of the tool is also provided for using a 3/8” (9.53mm) socket wrench as leverage.

- 7/8” (22.2mm) hexagon (E) for a fixed or adjustable wrench.

- A 13/16” (20.64mm) pentagon (F) is provided for using a penta-socket wrench.

Calibration

Tool torque can be checked by placing a 3/8” (9.53mm) torque wrench into the 3/8” (9.53mm) drive opening (D).

Load Break & Dead Break Elbows – T&D distribute Nexans Euromold and Elastimold Connectors for terminating and connecting MV-HV power cables onto transformers and switchgear bushings.

➡ T&D distribute a complete range of Utility Cable Tools for primary, secondary distribution and transmission applications – Utility Tool is a brand of Ripley for wire and cable jointing tools preferred by MV-HV jointers, splicers and linesmen.

Underground Cables or Overhead Lines – cable tools for 3.3kV, 11kV, 33kV, 66kV, 132kV and 400kV voltages