Solving 33kV Solar Cable Operational Issues Relating to Water Immersion

Published 28 Mar 2024

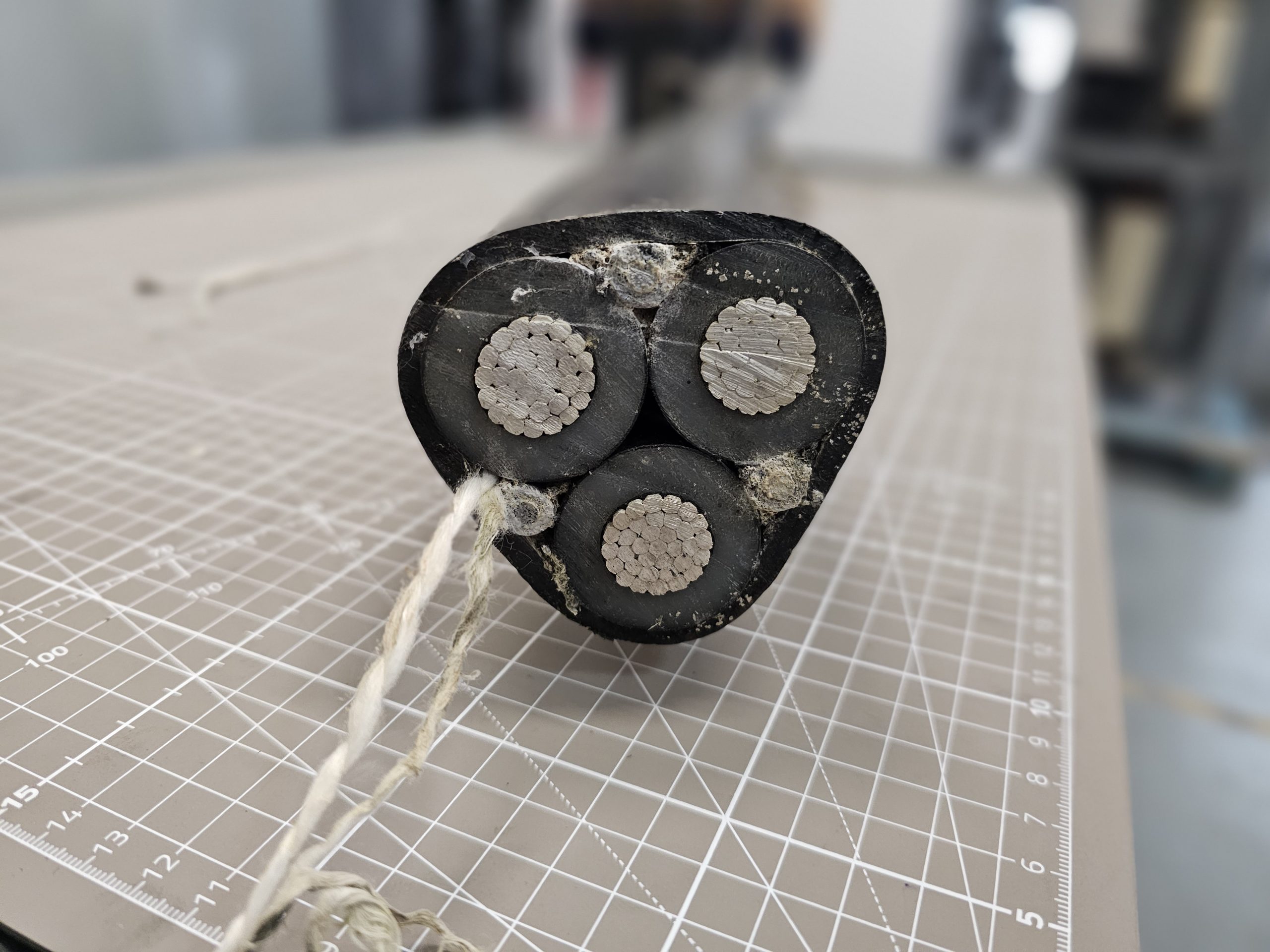

Operational Problem | Recurring 33kV Joint Failures Caused by Water Ingress to AXAL-F-TT Cables – a Medium Voltage Cable with XLPE Insulation 3 Core Construction.

Approved Technical Recommendation | Design, Specification & Supply of Customised Medium Voltage Polymeric Trifurcating Cable Joints (3 Core to 3 Single Core Cables).

Uploaded by Chris Dodds | Sales & Marketing Manager Thorne & Derrick

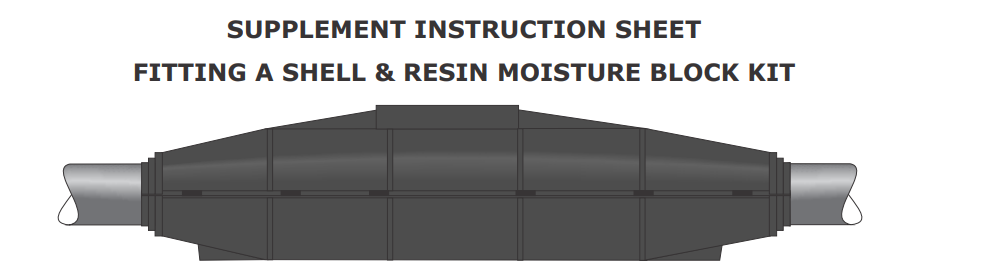

Thorne & Derrick have been working across several portfolios of renewable assets in the UK with Solar EPC’s to produce a reliable rectification to 33kV cable joint failures caused by water ingress. The Approved Polymeric Heat Shrink Trifurcating Joint with integral water-barrier features a “resin block” before the cable joint to prevent additional water from penetrating the seals of the joint shell.

Rather than use heat shrink shapes, such as a cable break-out, the client preference for the MV Joint was to include a combined Resin & Shell Water-Blocking Kit to overcome future water penetration compromising solar cable service, reliability and circuit integrity.

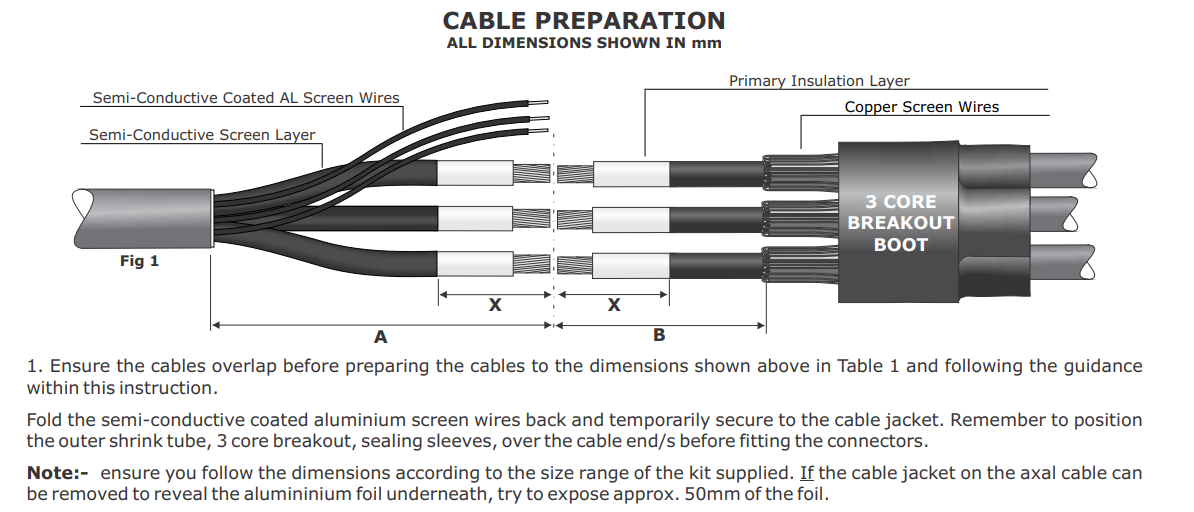

Cable reliability increases plant profitability and overall operational efficiency with reduced downtime caused by cable failures on PV power plants.

Water spread and the capillary effect under the cable sheath can cause excess stress on the seal leading to premature joint failure. The solution covered in the Jointing Instruction is to install the jointing encapsulation resin and shell 1000mm from the cable sheath and create a birdcage with the cores – note the core of the medium voltage cable must be separated to allow the resin to flow fully into all voids to eliminate air gaps and possible pathways for water ingress to travel into the Joint and minimise the risk of future failure.

With an expected shelf-life of 2-3 years the Joints have now been introduced to several solar farm sites as Strategic Spares – this provides the client with contingency planning, emergency response and immediate fault repair to any future 33kV cable failures.

The Joint features a “single-tube” shrink over the mechanical shearbolt connector overcoming the traditional multi-tube process with independent stress control and triple wall heat shrink tubes requiring additional working time. Repair and Jointing work should only ever be carried out by an Authorised & Competent Jointers.

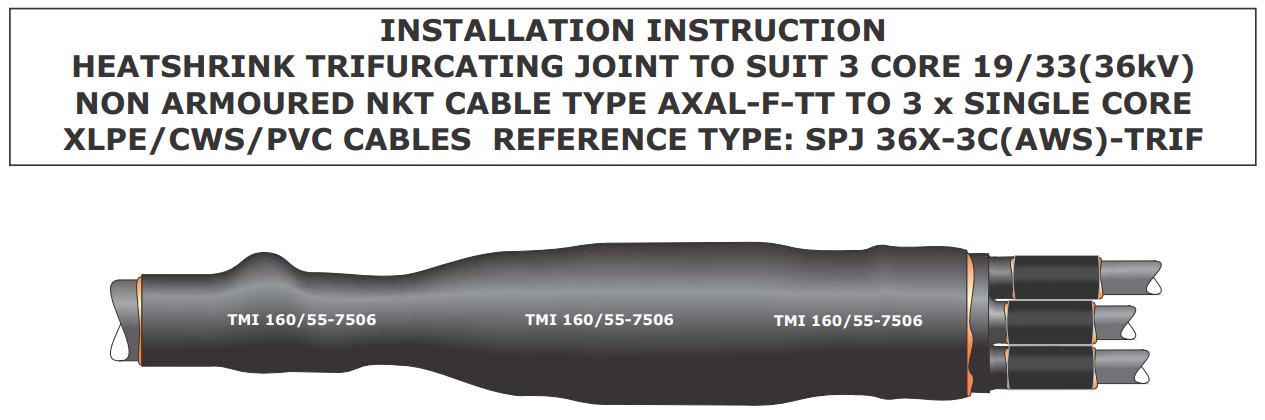

The existing faulted 33kV 3 Core AXAL-F-TT specification cable was jointed onto new 33kV BS7870 Single Core BS7870 type cables in accordance with the manufacturers Jointing Instruction – here is an excerpt from the JI Document, ownership of Shrink Polymer Systems.

REQUEST COPY OF JOINTING KIT INSTRUCTION

33kV Cable Specification | AXAL-F-TT 18/30 (36kV) 3 x 230 / 50 AL

AXAL-F-TT Cables with Aluminium, Compacted Stranded, Longitudinally Watertight Conductors, XLPE Insulation with Extruded, Bonded Semi -conducting Insulation Screen.

Further Reading

- Jointing, Grounding & Terminating DC Solar Cables

- Earthing Armoured Cables To Safely Protect LV AC Cables In The Solar Industry

sOLAR Cable Accessories & Electrical Equipment

600V to 66kV

Thorne & Derrick are Specialist Distributors to Solar EPC’s & High Voltage Jointing Contractors working on the design, construction and maintenance of UK, European and international projects supplying an extensive range of LV HV Solar Cables, Jointing, Substation & Electrical Eqpt.

Based in the UK, we are highly customer responsive and absolutely committed to providing a world-class service.

We stock LV HV Solar Cables, Accessories & Electrical Equipment to enable the construction, maintenance and operation of utility-scale PV installations – our products connect 600V/1500V solar cables into combiner boxes, inverters, transformers and energise switchgear up to 33kV/132kV for high voltage grid connections.

Since 1985, we have provided expert technical support and express delivery from extensive UK stocks to world-wide destinations.