Stress Control | MV Cable Terminations by 3M Electrical

Published 22 Sep 2020

3M Electrical

Stress Control Methods

Choosing Cable Terminations to Reduce Electrical Stress

The following information has been republished with kind permission of 3M Electrical.

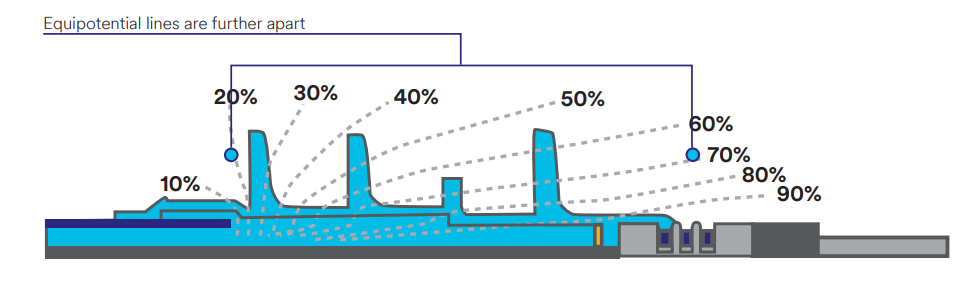

Traditional Geometric Stress Cone

This method reduces the electrical stress at the shield discontinuity by extending the shield and gradually increasing the thickness of insulation under the shield. The areas where there is a higher electrical stress receive additional insulation, as shown in Figure 2 below.

GEOMETRIC STRESS CONTROL

Geometric Stress Control – Figure 2

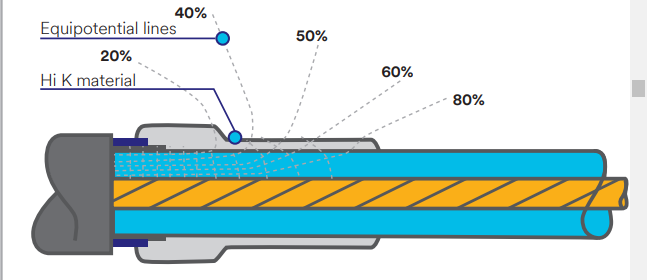

High Dielectric Constant (Hi K) Stress Control

This method lowers the electrical stress at the point of shield discontinuity by refracting the electrical stress. This allows the equipotential lines to spread out along the cable instruction interface. By doing this, the surface stress of the termination is greatly reduced, which improves cable termination performance and life expectancy shown in Figure 3 below:

CAPACITIVE STRESS CONTROL

Capacitive Stress Control – Figure 3

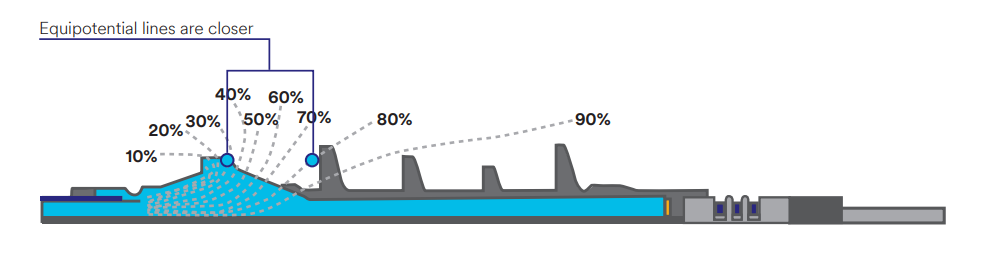

Geometric

Geometric

High Dielectric Constant

High Dielectric Constant

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Further Reading

-

Geometric vs. Capacitive Stress Control

Size: 5.47 MB

Geometric vs. Capacitive Stress Control

Size: 5.47 MB