Oil Filled Transformers | Driving Uptime Through Asset Winterisation

Published 01 Feb 2023

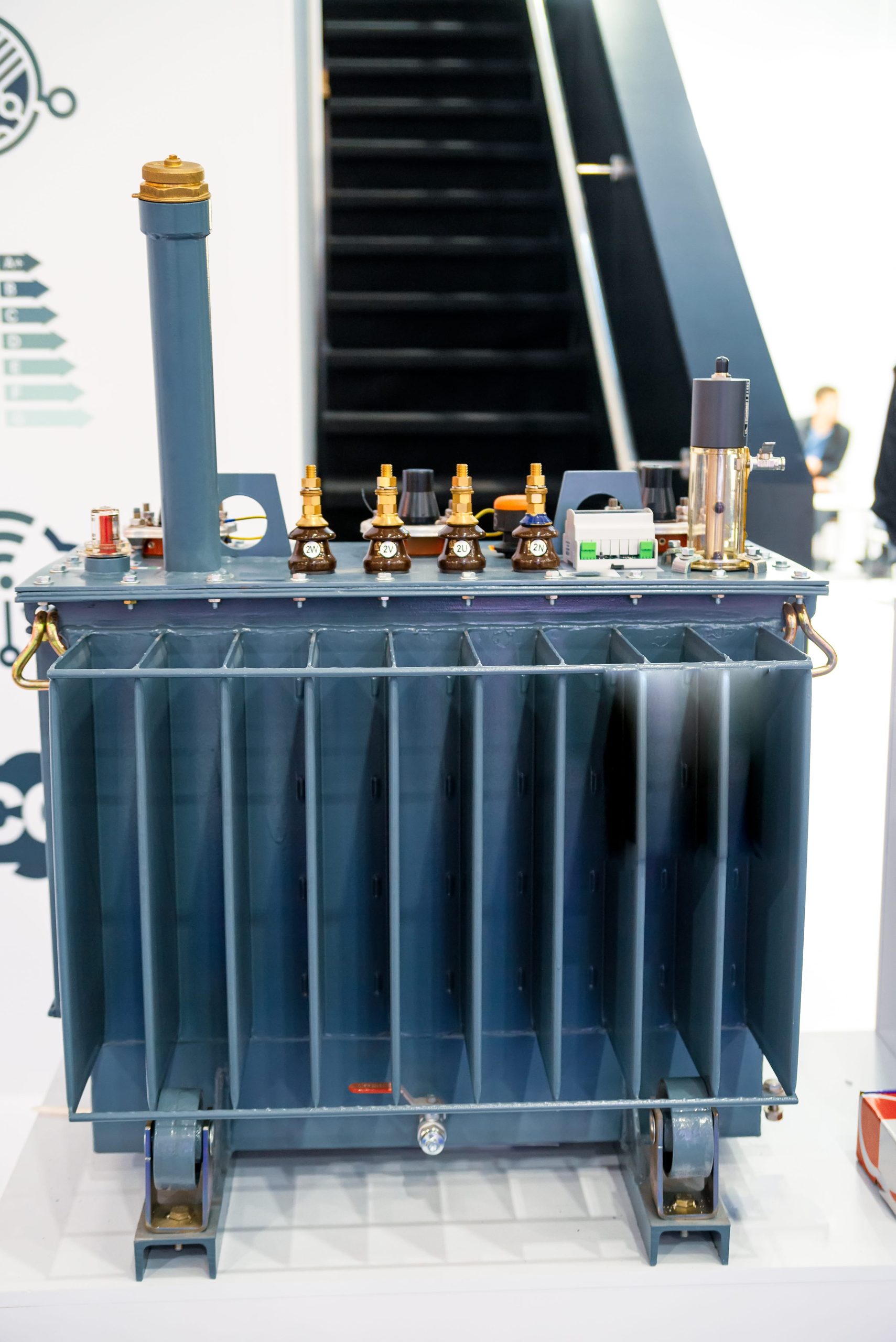

Oil Filled Transformers

in the Wind Power Industry

Are Low Oil Level Trips Causing Asset Downtime?

This Case Study covers the problems caused by low oil level trips on aging transformers, the impact it has on downtime, availability and power generation. It goes on to discuss how Thorne & Derrick assisted Ventient Energy in custom designing and supplying a fit for purpose electrical heating solution to overcome the problem and effectively Winterise assets preventing downtime.

Who should read this? – Asset Managers in the onshore wind industry with responsibility for managing and maintaining oil filled transformers.

Causeymire – Ventient Energy

Thorne & Derrick have recently worked in partnership with Ventient Energy to provide a bespoke electrical heating solution for an onshore wind application. After a number of site meetings and application surveys with the client to understand the problem, T&D proposed a bespoke heating jacket solution to prevent downtime due to low temperatures.

Jon Priddy of Ventient Energy describes the problem

“For those of you managing assets with ageing oil filled transformers you may find this useful. If you do you’ll know that the tank expands and contracts with heat and cold. As they age the tank loses that capacity to contract and so now you have a bigger volume but the same amount of oil and usually a very finely tuned oil level sensor which as we know is a primary safety and protection feature.

Come the winter and those high pressure low wind speed days and bang, we have a trip. I have spent many a late night with the site team topping up, getting the contacts to close and getting everything back on. The result is downtime, a hit on availability and a hit on generation.

What’s the answer? A hugely costly campaign to change out all the transformers, a nearly as expensive retrofit of conservators (if you have the room and a good design), heating the transformer compartment in a large drafty steel tower fighting the physics of heat loss.

Obviously it doesn’t affect every site but typically anything over 15 years where the tank has lost that capacity to contract back to normal shape after the summer or high generation is a candidate.”

The nature of the problem included a number a variables and it was agreed that T&D would provide 5 trail heating jackets which would be put into use throughout the winter of 2022/23. The jackets were installed to the “top 5 offenders” during previous winters. The trials have proven successful and the client experienced no outages as a result of low oil trips during one of the harshest UK winters on recent record.

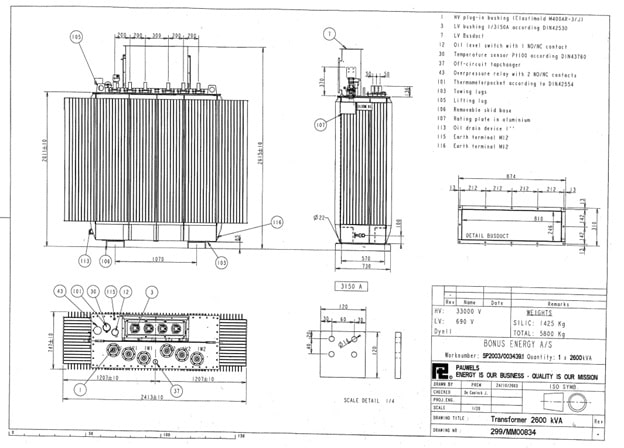

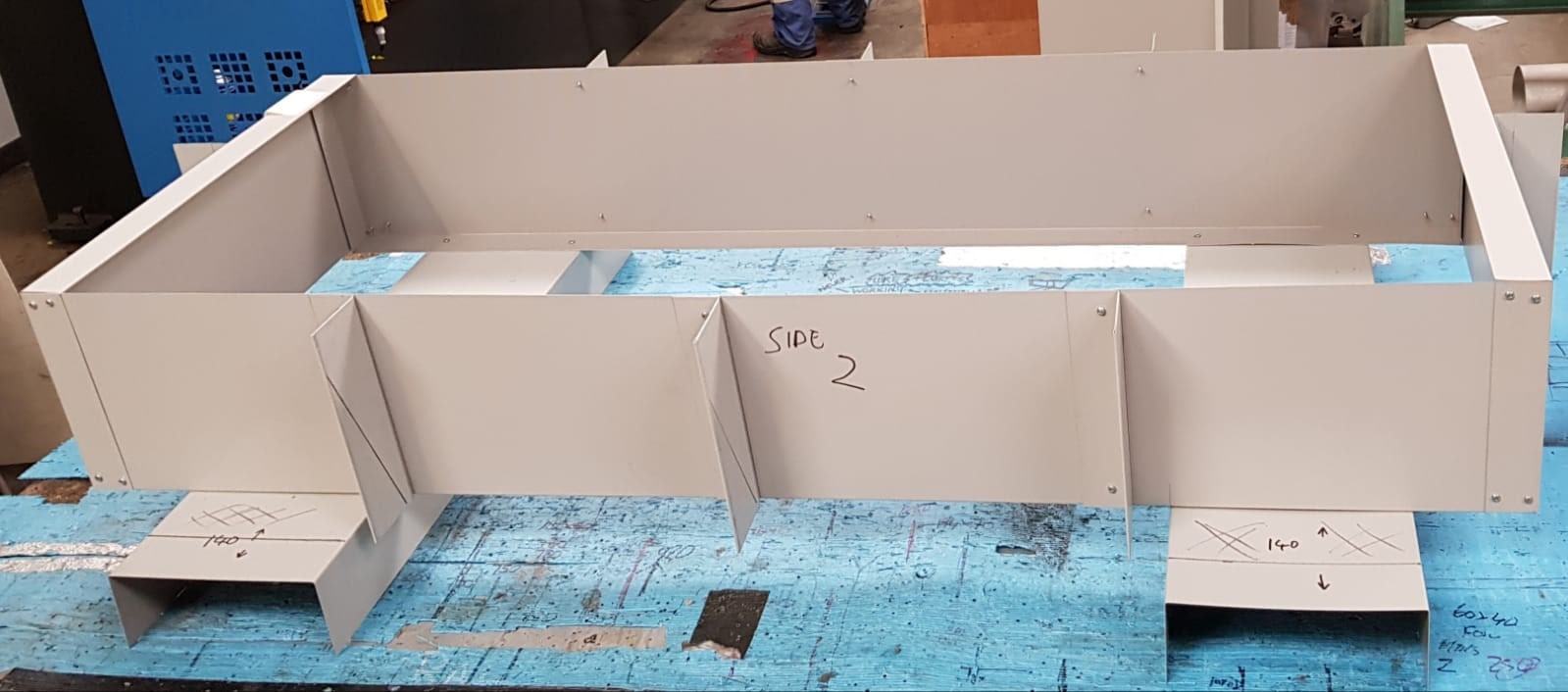

Pictured – fabricated model of the bottom of the transformer was made using the measurements taken from site survey. This meant the electrical heating jackets could be manufactured and test fitted prior to delivery.

The Solution for Oil Filled Transformers

Ventient approached Thorne and Derrick with a request for feasibility on applying a thermostatically controlled electric heating blanket to the base of the transformer with a view to stopping the oil from contracting to the point of a trip. This typically applies on high pressure (clear skies) low wind speed days and nights when there’s little in the way of current going through the transformer and temperatures drop to or minus zero.

Consideration had to be given to:-

Jacket Design – the client needed a solution which was simple and could be easily fitted, ideally as a single piece. The jacket also had to provide a very good fit as any additional heat losses may have negatively affected the overall performance. Representatives from T&D made the journey to Causeymire wind farm to carry out a site survey.

Power Supply – the power available was restricted due to only a single socket outlet being available.

Energy Efficiency – the design needed to be fit for purpose but using excessive power to solve the problem wasn’t an option.

Heat Loss – T&D have many years trace heating design experience and have carried out thousands of heat loss calculations for pipes, tanks and vessels. This was particularly challenging as we didn’t know the optimum oil temperature that would prevent it contracting enough to cause a trip. A safety factor had to be built into the design without using unnecessary power/energy.

Maintenance – any solution needed to be low/zero maintenance due to the remote location. The solution offered a fit and forget heating jacket. Once commissioned the jackets will operate using built in digital control thermostat. Any maintenance/inspections can be carried out alongside other routine maintenance.

Before & After Jacket Was Fitted to the Oil Filled Transformers

Heating Blanket For Oil Filled Transformer

Custom Heating Solution

Bespoke Heating Jacket

Client feedback

“The blankets were installed last year and wired up in November. A winter with some spectacularly low temperatures and some nights with low wind speeds has followed. And until 2 weeks ago, no low oil trips. This is the first winter in the last 6 where we haven’t had the problem.

Almost by way of verification the low oil trip 2 weeks ago occurred on one of the transformers without the blankets. The blankets are currently set to come on at 5°C ambient air temperature.

As usual with these things team work makes for the dream work. A huge shout out to Terry McDonald of Thorne & Derrick for crunching the numbers, doing the physics and coming up with a design, that was easy to fit and forget.

The great support and encouragement from the Ventient team, Alexa Belsham, Rui Meneses, who were willing to spend the cash and give it a try. For the support as ever from Tony Crombie who helped make the case and for Colin McIver of DWT for coming up with a power supply solution. A true “can do” team and collaboration.

So in short, it looks like we have a fix for this expensive (in every sense) issue with ageing oil filled transformers in colder climes.”

T&D have over 30 years process heating experience and are your pro-active problem solvers. If you are reading this and experiencing similar issues, please reach out to T&D and we will be happy to arrange an initial meeting to discuss your requirements.

Who are Ventient Energy?

Ventient Energy is a dynamic, pan-European renewable energy business and is one of the leading generators of renewable energy in Europe. They are Europe’s leading independent onshore wind group, with over 140 generating sites.

Thorne & Derrick distribute the most extensive range of MV HV Medium & High Voltage Cable Joints, Terminations & Connectors from manufacturers including 3M, Prysmian, Nexans Euromold, Pfisterer CONNEX & SEANEX and Shrink Polymer Systems.

Heat shrink, cold shrink, push-on and slip-over cable accessories enable the jointing, terminating and connection of 11kV-33kV and 66kV-132kV cables to oil, air or gas insulated switchgear, transformers, motors and overhead lines distributing electricity at medium/high voltages. Thorne & Derrick hold large stocks of 11kV 33kV 66kV Joints & Terminations suitable for XLPE, PILC and EPR cables, in both heat shrink and Cold Shrink technologies, to service the medium/high voltage power cable accessory requirements of UK and international customers.