Basics of Cable Design and Engineering for Power Systems

Published 29 Jan 2024

Guest Article : Authored by Ryan Smith MSc MIET | Owner of EasyCableSizing.com

As an Electrical Engineer, I’ve always been fascinated by the “hows and whys” in the design and engineering of power cables. In this Article, I delve into the essential aspects from the core components of a power cable to the considerations in choosing the right materials.

components of a power cable to the considerations in choosing the right materials.

Key highlights include:

- the critical roles of conductors, insulation, and sheathing

- a comparative look at copper and aluminium in cable applications

- insights into the evolving world of eco-friendly materials in cable design

- importance of understanding electrical properties like conductance, resistance, capacitance, and inductance

I also discuss the significance of standards like IEC 60287 and IEC 60502 in cable sizing, essential for anyone working with MV and HV power cables. Whether you’re a fellow engineer, a student, or just curious about the field, I believe there’s something valuable for everyone in this piece.

→ See original article here!

Table Of Contents

1.Introduction to Cable Engineering

1.1 Definition and Scope

2. Cable Construction Basics

2.1 Core Components of a Power Cable

2.1.1 Conductors

2.1.2 Insulation

2.1.3 Sheathing and Jacketing

2.2 Types of Power Cables

2.2.1 Low Voltage Cables

2.2.2 Medium and High Voltage Cables

3 Material Selection in Cable Design

3.1 Conductive Materials: Copper vs. Aluminium

3.2 Insulation Materials: XLPE, PVC, and Others

3.3 Advances in Eco-friendly Materials

4 Electrical Properties of Cables

4.1 Conductance and Resistance

4.2 Capacitance and Inductance

4.3 Impedance Considerations

5 Cable Sizing and Capacity Considerations

5.1 Calculating Current Carrying Capacity

5.2 Factors Influencing Cable Sizing

5.3 Utilizing Standards for Sizing

5.3.1 IEC 60287 Standard

5.3.2 IEC 60502 Standard

6 Key Takeaways

Introduction to Cable Engineering

Definition and Scope

Cable engineering is a specialised domain focusing on the design, implementation, and optimisation of electrical power cables. This field encompasses a range of activities from material selection to performance testing, ensuring that cables meet the demands of modern electrical networks.

Cable construction Basics

Core components of A POWER CABLE

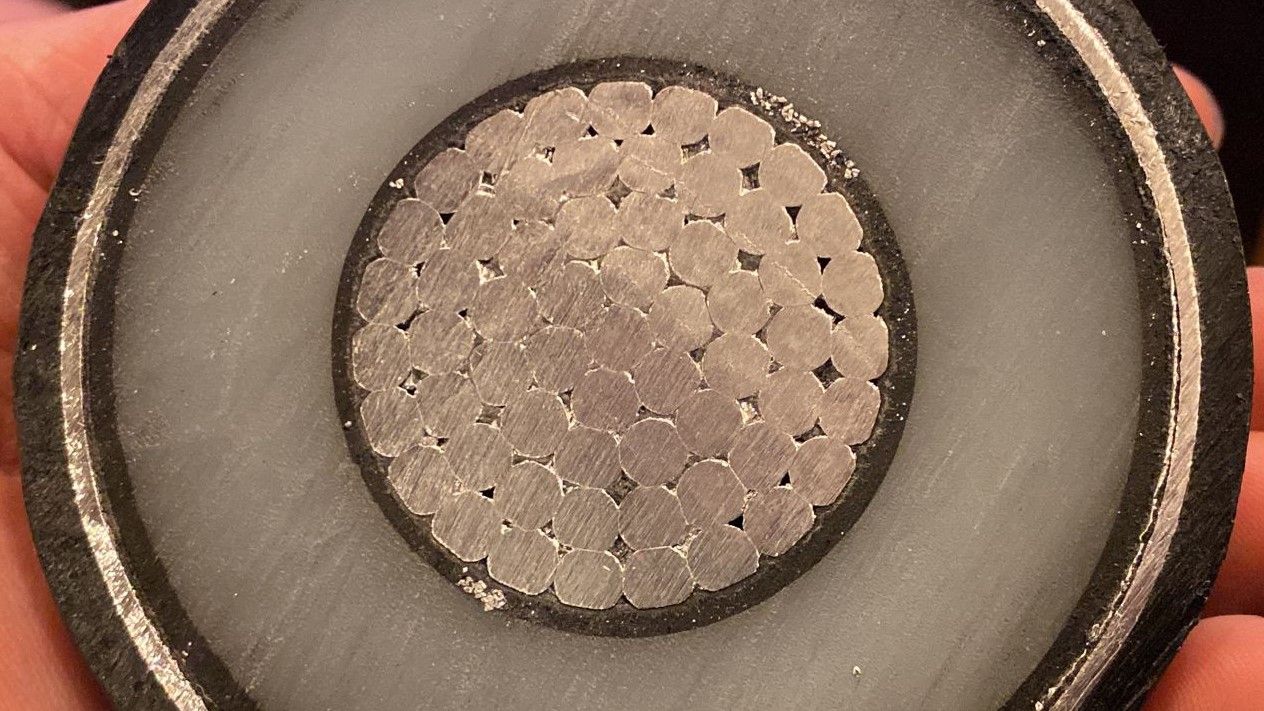

Underground power cables consist of a minimum of two components, a conductor and insulation, however these are usually accompanied by other elements, each playing a critical role in overall functionality:

cONDUCTORS

Conductors are the principal element of a power cables, responsible for transmitting electricity. They are typically made of materials like copper or aluminium, chosen for their excellent conductivity and durability. In other applications where conductors are required, other materials are often used, like gold, but these aren’t feasible for power applications due to their high cost.

iNSULATION

Insulation in power cables primarily provides segregation from a conductor and other conductive materials, whether they’re intended to be conductors or not, but also protects it from environmental factors.

Sheathing and Jacketing

Sheathing and jacketing provide an additional layer of protection to cables, safeguarding against physical damage and environmental factors. This layer is crucial for cable longevity and reliability.

Types of Power Cables

Power cables are categorised based on their voltage capacity:

Low voltage Cables

Low voltage cables are designed for applications with voltage requirements commonly up to 1000V. They are commonly used in residential and commercial settings for everyday electrical needs, and in industrial settings for smaller loads. Learn more about low voltage, heavy-duty industrial cables like the H07RN‑F rubber cable in our detailed selection guide.

Medium and High Voltage Cables

Medium and high voltage cables cater to more demanding applications, such as industrial plants, generation, and power transmission lines. They are able to handle higher voltages and are key in large-scale power distribution.

Material Selection in cable design

Conductive materials: Copper vs. aluminium

The two main materials used for conductors are copper and aluminium, due to their wide availability and relatively low cost.

- Copper, known for its superior conductivity and durability, is often preferred for certain applications, despite its higher cost.

- Aluminium, being lighter and more cost-effective, is a viable alternative, especially for large-scale power transmission.

Insulation Materials: XLPE, PVC, and Others

Different insulation materials like XLPE, PVC, and EPR play a crucial role in cable performance:

- XLPE (Cross-Linked Polyethylene): Known for high temperature resistance and excellent electrical properties, ideal for high voltage applications.

- PVC (Polyvinyl Chloride): Offers flexibility and durability, used in a wide range of cable types.

- EPR (Ethylene Propylene Rubber): Notable for dielectric strength, flexibility, thermal stability, suitable for high stress environments.

- Others: Includes materials like Teflon and Rubber, chosen for specific applications based on properties like fire resistance, low toxicity, or extreme environmental conditions.

Advances in Eco-friendly Materials

The cable industry is evolving towards eco-friendly materials like polypropylene (PP) to minimize environmental impact. PP stands out for its excellent insulating properties and recyclability, making it a promising material for next-generation power cables. However, its application in cable insulation still faces challenges, such as optimising its mechanical and electrical properties. This drive towards sustainable materials is redefining cable technology, balancing environmental considerations with performance requirements. For an in-depth understanding, read more about the potential of PP in power cable insulation in this research article.

Electrical properties of cables

Conductance and resistance

Understanding the conductance (G) and resistance ® of power cables is essential for evaluating their performance. These properties are inversely related, where G=1⁄R. Conductance represents a cable’s ability to allow electric current flow, while resistance quantifies the opposition to current flow. This affects cable efficiency, with lower resistance implying less energy loss as heat. Factors such as material type, cross-sectional area, and temperature influence these properties.

To learn more about the impact of resistance in power systems, consider reading this comprehensive guide on resistance and its effects.

Capacitance and Inductance

Capacitance © and inductance (L) are key factors in cable design, affecting how cables react to different electrical loads and frequencies. Capacitance in cables arises from the electric field between conductors, typically calculated using where is the permittivity of the insulating material, the area of the conductor, and the distance between conductors. Inductance, on the other hand, is influenced by the magnetic field around the conductor and is given by , where is the permeability of the material, the number of turns in the coil, the area, and the length of the coil.

Impedance Considerations

Impedance (Z) in cables, a combination of resistance, inductance, and capacitance, is crucial in AC power systems. It can be represented as , where is the inductive reactance and the capacitive reactance. Impedance affects signal quality and power loss in cables, and its proper management is vital for maintaining the integrity and efficiency of electrical systems.

For an in-depth understanding of impedance and its impact on power systems, you might find this resource on impedance in AC circuits useful.

Cable sizing and capacity considerations

Calculating current carrying capacity

There are various methods used to calculate the current carrying capacity of cables (or ampacity), although the two methods predominantly referenced and used are IEC 60287 and Neher-McGrath. Both IEC 60287 and Neher-McGrath methods consider the heating of a conductor, and the cable’s and surrounding mediums’ ability to dissipate the heat until thermal equilibrium is met. An increase in current results in an increase in temperature, and the less thermal resistivity the cable and surrounding medium have, the more current can be carried.

Factors Influencing Cable Sizing

A principal consideration in cable sizing is the insulation selected for the conductor, as this determines the maximum temperature that can be reached before causing overheating and unnecessary stress or damage to the cable. Beyond that, it is primarily the surrounding medium and installation conditions that influence the thermal resistivity.

For cables installed underground, the soil itself has a thermal resistivity value to be considered. If sand, bentonite, or concrete are used, their own thermal resistivity values and geometry are incorporated into the formulas to determine the cable’s ampacity. If a cable is installed in a duct, the geometry, thermal resistivity of the duct itself, and the filling medium (such as air or bentonite) must also be considered.

Another major factor affecting the ampacity of cables is their proximity to other heat sources, such as other circuits (which are assumed to reach 90°C if insulated with XLPE), hot water pipes, steam pipes, etc. This mutual heating significantly impacts the ampacity calculations, especially in shared trenches or when cables are installed in ladders or trays.

Utilizing Standards for Sizing

When determining the appropriate size for power cables, adhering to established standards is crucial. These standards provide a comprehensive framework for evaluating various factors, ensuring that the chosen cable meets both current and future demands of electrical networks while adhering to safety and efficiency guidelines.

IEC 60287 Standard

The IEC 60287 standard is renowned for its systematic approach to cable sizing. It accounts for numerous factors, including conductor temperature, load pattern, cable laying conditions, and the thermal resistivity of the surrounding environment. This standard is particularly valued for its detailed thermal model, essential in accurately predicting cable behaviour under varying operational conditions.

EasyCableSizing.com plans to integrate this model into its platform, enhancing its cable sizing capabilities.

IEC 60502 Standard

IEC 60502 covers the requirements for the manufacture and testing of cables ranging from 1kV to 30kV. It includes tables of multipliers used against standard cable ampacity tables to determine adjusted ampacities based on specific conditions. These tables are derived from methodologies in IEC 60287, offering a practical guide for cable system development.

EasyCableSizing.com utilizes the IEC 60502 methodology in a user-friendly manner, helping users quickly and efficiently determine cable ampacities. This approach simplifies the complex process of cable sizing, making it accessible to a wider range of professionals and ensuring compliance with international standards. In Understanding the IEC 60502 Sizing System: A Double-Edged Sword this standard in particular is discussed in more detail.

Key Takeaways

- Cable Engineering’s Core Focus: Emphasizes the design, implementation, and optimization of electrical power cables, highlighting its crucial role in modern electrical networks.

- Components of Power Cables: Details the significance of conductors, insulation, and sheathing in cable construction, and their impact on cable functionality and durability.

- Conductive Material Choices: Discusses the use of copper and aluminium in power cables, outlining their advantages based on conductivity, durability, and cost-effectiveness.

- Insulation Material Varieties: Explores different insulation materials like XLPE, PVC, EPR, and their roles in high voltage applications, flexibility, and thermal stability.

- Eco-friendly Material Trends: Addresses the shift towards sustainable materials like polypropylene in the cable industry, balancing environmental considerations with performance requirements.

- Electrical Properties in Cables: Analyses essential properties such as conductance, resistance, capacitance, and inductance, crucial for cable efficiency and performance.

- Impedance in AC Power Systems: Highlights the importance of impedance, combining resistance, inductance, and capacitance, and its effect on signal quality and power loss.

- Current Carrying Capacity Methods: Compares IEC 60287 and Neher-McGrath methods for calculating ampacity, focusing on thermal equilibrium and thermal resistivity.

- Influences on Cable Sizing: Discusses how insulation, installation conditions, and surrounding medium impact cable sizing and thermal resistivity.

- Standards for Cable Sizing: Underlines the importance of adhering to standards like IEC 60287 and IEC 60502 for accurate and safe cable sizing, integrating these standards into EasyCableSizing.com for user-friendly access.

ib vogt – company

ib vogt is firmly committed to supporting the decarbonisation of the global electricity sector. The company focuses on the global development of turnkey PV plants and battery storage projects as well as the expansion of its IPP portfolio. In these areas, the company performs all integral services of the value chain from development, financing, and EPC, to O&M and asset management.

Headquartered in Berlin, Germany, ib vogt has established various offices across Europe, Asia Pacific, the Americas, and Africa as part of its presence in over 30 countries. The company works together with numerous partners globally, augmenting its in-house team of over 700 staff. ib vogt has built or has in construction more than 3.1 GW of PV power plants globally with a project pipeline of more than 45 GWp.

Thorne & Derrick distribute the most extensive range of MV HV Medium & High Voltage Cable Joints, Terminations & Connectors from manufacturers including 3M, Prysmian, Nexans Euromold, Elastimold, Pfisterer CONNEX & SEANEX.

Heat shrink, cold shrink, push-on and slip-over cable accessories enable the jointing, terminating and connection of 11kV-33kV and 66kV-132kV cables to oil, air or gas insulated switchgear, transformers, motors and overhead lines distributing electricity at MV HV.

T&D hold large stocks of 11kV 33kV 66kV Joints & Terminations suitable for XLPE, PILC and EPR cables, in both heat shrink and Cold Shrink technologies, to service the medium/high voltage power cable accessory requirements of UK and international customers.