Electrical Safety Management | Solar Farms & Electrical Safety

Published 23 Jan 2023

Electrical Safety

Solar Farms

-

Guest Article By Paul Hopton Deputy Managing Director at Electrical Safety UK Limited

Thorne & Derrick distribute electrical safety equipment to substation engineers, cable jointers, overhead linesmen and utility workers – this includes insulating gloves, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out maintenance on LV-HV switchgear, substations, cables and electrical equipment in the solar industry.

Electrical Safety Products for LV MV HV Cables, Conductors, Substations & Overhead Lines

Electrical Safety UK

Electrical Safety UK have helped many companies in different industries in a number of locations around the World to improve their electrical safety management systems.

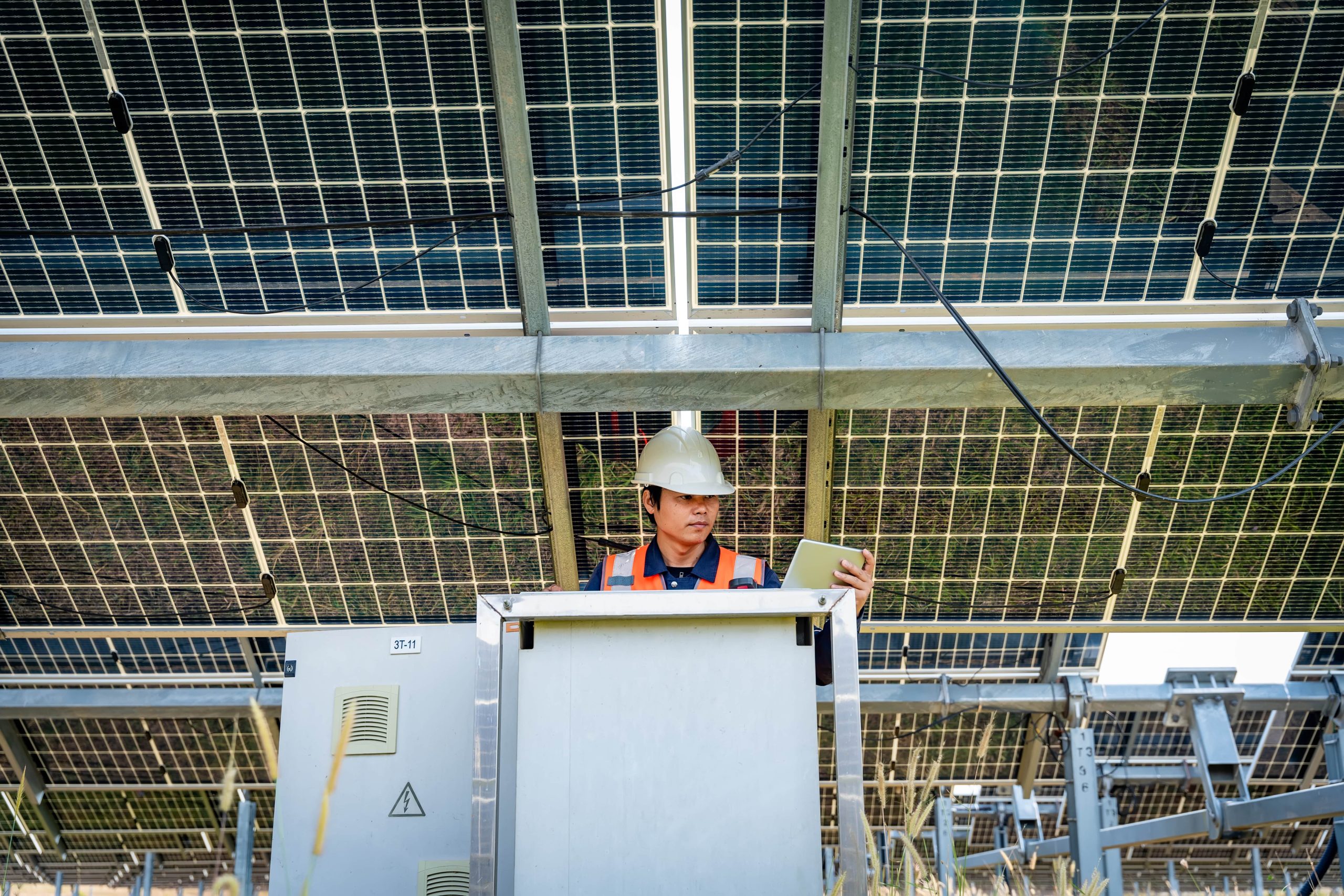

In this Article we are going to focus on Solar Farms and discuss whether there any hazards that may be specific to that industry.

We recently carried out an electrical safety audit in the Middle East at one of the largest solar farms in the world. The brief was to carry out an audit of their current operations and safety management system to identify if any improvements could be made.

We started by interviewing Electrical Managers, Supervisors and Tradesmen to ascertain where they had good practice and where improvements could be made. The scope of these interviews covered but was not limited to:

- Electrical Safety Policy

- Electrical Safety Rules

- Tools, Test Equipment and Test Leads

- Competency and Authorisation

- Asset Integrity and Maintenance

- Portable Electrical Apparatus

- Arc Flash Risk Management

- Electric Shock Risk Management

- Lightning Protection

- Toxic Gases

- Isolation Practices

- Electrical Accident Investigation and Root Cause Analysis

- Software and Device Parameter Backups

- Reliability and Bad Actors

- Safe Systems of Work including Switching Programs and Earthing Diagrams

We also carried out site surveys and asked personnel who were working on site about electrical safety and the management of electrical risks.

Results

We identified several areas where there were opportunities to improve. These were presented to the site management team in a feedback presentation and more formally in a report. The findings showed significant opportunities in Arc Flash Risk Management, Isolations and Electrical Shock Risk Management.

Hazards specific to Solar Farms

The main issue specific to Solar Farms that we identified was with the Solar Panels themselves as they generate electricity. The good news is that Solar Farms are modular and so it is easier to produce isolation and safe working procedures, than for more typical industrial or commercial electrical distribution systems.

“Test before touch” or “Test for dead” processes are very important. You should ensure that the correct type of test equipment is used. Voltage indicators should be tested immediately before and after use with a proprietary proving unit.

There are also a lot of power inverters and other enclosures out in the field that should be shrouded to IP2X to minimise electric shock risk during fault finding activities. As the Solar Farm gets older, it is important to make sure that the IP2X protection is maintained by auditing and inspection especially during and after maintenance activities.

Electrical Safety Management Systems

I think it is fair to say that Solar Farms have not been around as long as many industrial and commercial electrical networks and can be operated by organisations that do not have a long history of electrical safety management experience. This lack of experience can lead to gaps in their Electrical Safety Management Systems.

Unfortunately, failures of an Electrical Safety Management System can result in serious injury or fatality. Fortunately, these events are rare but because of the complacency that can result from their scarcity, when the holes in the Swiss cheese line up, the worst can happen.

Far better to have someone independent to the Organisation to audit your Electrical Safety Management System to prevent the accident before it happens.

Solar Farms can sometimes be operated and maintained by the Company that designed and installed them rather than the owner. Dependent upon the Company supplying the Solar Farm, they may or may not have a great deal of operational and electrical safety management experience. If they do lack experience, they might be more likely to have an electrical accident.

The Company owning the asset (Electrical Duty Holder) might not take kindly to the exposure to public/regulatory scrutiny that this would bring.

READ Blog | Ten Most Common Errors in Arc Flash Studies

Arc Flash Studies

Calculating the arc flash hazard for each of piece of equipment on a Solar Farm should cost significantly less that carrying out an arc flash study on a typical industrial or commercial electrical distribution system.

The reason for this is that Solar Farms tend to be very modular in their construction. Therefore detailed modelling of one of the modules can be quickly and cheaply replicated many times for the rest of the network.

This obviously reduces the overall cost of the arc flash study for a Solar Farm versus other types of electrical networks.

About Electrical Safety UK

Electrical Safety Management is our core business. We provide expert consultancy and advice services for blue chip organisations across Europe concerned with the safe management of risk associated with all electrical work activities.

Electrical Safety UK provide a multi-faceted holistic approach including a full electrical safety management programme, project management and policy documentation all bespoke to the client’s requirements including fully accredited and bespoke training courses and personnel assessment programmes.

2 Genesis Business Park

Sheffield Road

Rotherham

S60 1DX

Tel: 0800 652 1124

Tel: 01709 961 666

Email: [email protected]

To find out more information click here

THORNE & DERRICK

SPECIALIST ELECTRICAL DISTRIBUTOR

Thorne & Derrick are Specialist Distributors to Solar EPC’s & High Voltage Jointing Contractors working on the design, construction and maintenance of UK, European and international projects supplying an extensive range of LV HV Solar Cables, Jointing, Substation & Electrical Eqpt. Based in the UK, we are highly customer responsive and absolutely committed to providing a world-class service.

We stock LV HV Solar Cables, Accessories & Electrical Equipment to enable the construction, maintenance and operation of utility-scale PV installations – our products connect 600V/1500V solar cables into combiner boxes, inverters, transformers and energise switchgear up to 33kV/132kV for high voltage grid connections.

Since 1985, we have provided expert technical support and express delivery from extensive UK stocks to world-wide destinations.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M Cold Shrink, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Further Reading

- Solar Farms | Insulate, Connect & Protect LV HV Electrical Cables & Equipment

- Electrical Safety Management | Solar Farms & Electrical Safety

- Jointing, Grounding & Terminating DC Solar Cables

- PR: Solar Industry Relaxes Planning Laws For Large Scale Battery Storage

- UKPN 33kV Primary Substation Construction – Swanland Solar Farm