Euromold Connectors | Properties & Performance – 40 Years of Market-Leadership

Published 27 Sep 2022

Euromold Connectors

Properties of EPDM & Silicone Rubbers

For approximately 40 years Euromold has been formulating and moulding rubber compounds. The knowledge and skill gained over this extensive period has overcome many obstacles and are a great asset for the future of the brand and the Euromold connectors.

The resultant hydrocarbon-based elastomers have all advantages of general purpose rubbers but its performances excel in electrical strength and resistance to environmental conditions.

The silicone rubbers used by Euromold connectors in its cold-shrinkable and slip-on terminations have been selected for their excellent tracking resistance as well as their unique hydrophobic properties.

Thorne & Derrick have an International Distribution Agreement with Nexans Power Accessories UK and are their main stockists and suppliers for their range of Heat Shrink Joints & Terminations up to 66kV as well as their Euromold connectors.

OZONE/CORONA RESISTANCE

The outstanding resistance to corona is due to the ability of the EPDM rubber to withstand ozone and other chemical compounds formed by discharges and its resistance to heat.

CHEMICAL RESISTANCE

Products made from EPDM rubber resist attacks made by many acids, alkalis, detergents, phosphates, esters, ketones, alcohols and glycols. They give particularly outstanding service in the presence of hot water and high pressure steam. Like all hydrocarbon-based elastomers, EPDM is not resistant to hydrocarbon solvents and oils or chlorinated hydrocarbons.

RADIATION RESISTANCE

EPDM connectors are also installed in nuclear containment areas.

RESISTANCE TO MECHANICAL ABUSE

EPDM rubber has good resistance to compression, cutting, impact, tearing and abrasion over a wide temperature range.

ELECTRICAL PROPERTIES

| Typical Values | EPDM Connectors | Silicone | |

| Insulation | Conductive | Insulation | |

| Dielectric strength (kV/mm) | 33 | – | 24 |

| Dielectric constant | 2.7 to 3.1 | – | 2.6 |

| Dissipation factor (x 10-3) | 2.5 | – | 4 |

| Volume resistivity at 20 °C (Ohm-cm) | 1014 | 50 | 1015 |

OTHER Euromold PROPERTIES

| Typical Values | EPDM Connectors | Silicone | |

| Insulation | Conductive | Insulation | |

| Specific gravity (kg/dm³) | 1.33 | 1.12 | 1.15 |

| Tensile strength (N/mm²) | 4.8 | 11 | 8.5 |

| Shore hardness (Shore A) | 65 | 80 | 47 |

| Elongation (%) | 400 | 450 | 700 |

| Abrasion resistance | good | excellent | poor |

| Heat ageing | good | good | good |

| Temperature range (°C) | -60 to +130 | -60 to +130 | -80 to +200 |

| Resistance to: | |||

| -U.V. | good | good | good |

| -Ozone | excellent | excellent | excellent |

| -Sunlight | outstanding | outstanding | outstanding |

| -Water absorption | very good | very good | excellent |

| -Solvent | poor | poor | poor |

| -Hydrocarbon oil | poor | poor | good |

| -Silicone oil | good | good | poor |

RESISTANCE TO THE ENVIRONMENT

EPDM rubber has properties comparable with the best speciality elastomers in resistance to weather. Accelerated life and salt spray tests suggest excellent properties which have been proven in practice by more than 40 years experience in widely varied applications all over the world. Silicone rubber has outstanding long-term resistance to weather in aggressive environments (industrial, coastal and desert climates).

RESISTANCE TO WATER

Water has little effect on the properties of EPDM hydrocarbon rubber. Even long immersion in hot water results in minimal loss of tensile strength. Tests also show a very low degree of water absorption. Silicone rubbers retain their surface hydrophobicity which is a considerable advantage for outdoor applications.

INTERNATIONAL PROTECTION CLASS

By design, Euromold connectors are protecting live elements of the connection against ingress of dust and water. The protection class per IEC 60529 is IP67.

PROPERTIES OF SILICONE LUBRICANT

The high viscosity silicone grease has been chosen for both its lubrication and dielectric properties. It is used as a lubricant when installing all premoulded rubber accessories on epoxy bushings as well as on the core insulation of dry cables.

Its selection is the result of several years of evaluation by Euromold of many types of silicone grease. Silicone grease displays a high level of long-term lubricating stability avoiding any ageing effects (e.g. the risk of sticking).

It also offers excellent dielectric properties assuring good performance at high voltage interfaces. In addition, the grease contributes in making interfaces watertight. It is completely compatible with all premoulded rubber accessories as well as with polymeric insulated cables.

USES

Use of this grease has proven to be of value in the installation of accessories in series and for operations such as greasing interfaces after disconnection. The installation instructions included in each product package detail clearly the application of the silicone grease.

ELECTRICAL STRESS

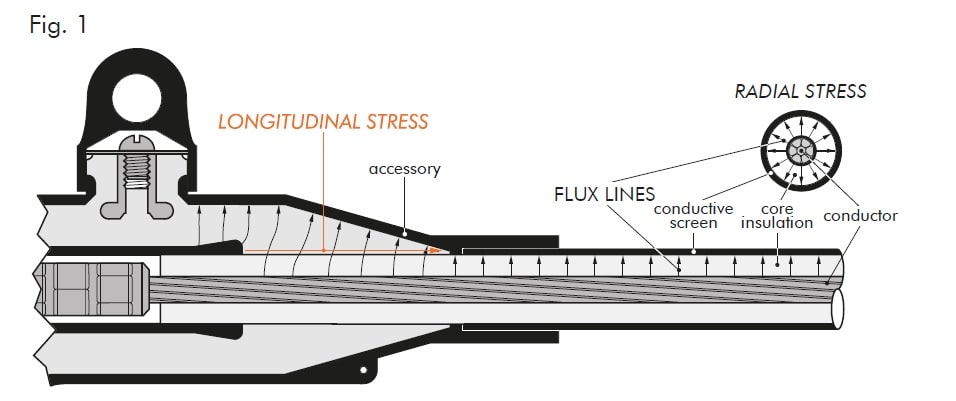

ELECTRICAL STRESS IN CABLES

The design and construction of screened power cables is primarily based on two types of electrical stress – a radial stress which can be represented by flux lines and a longitudinal

stress on the surface of the insulation where the screen has been removed. (Fig. 1).

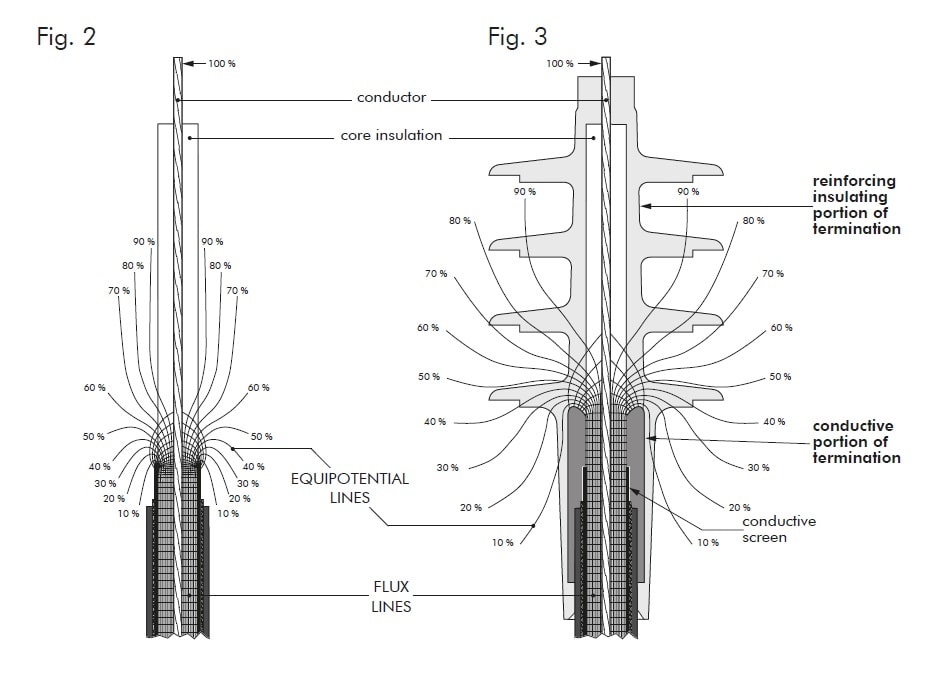

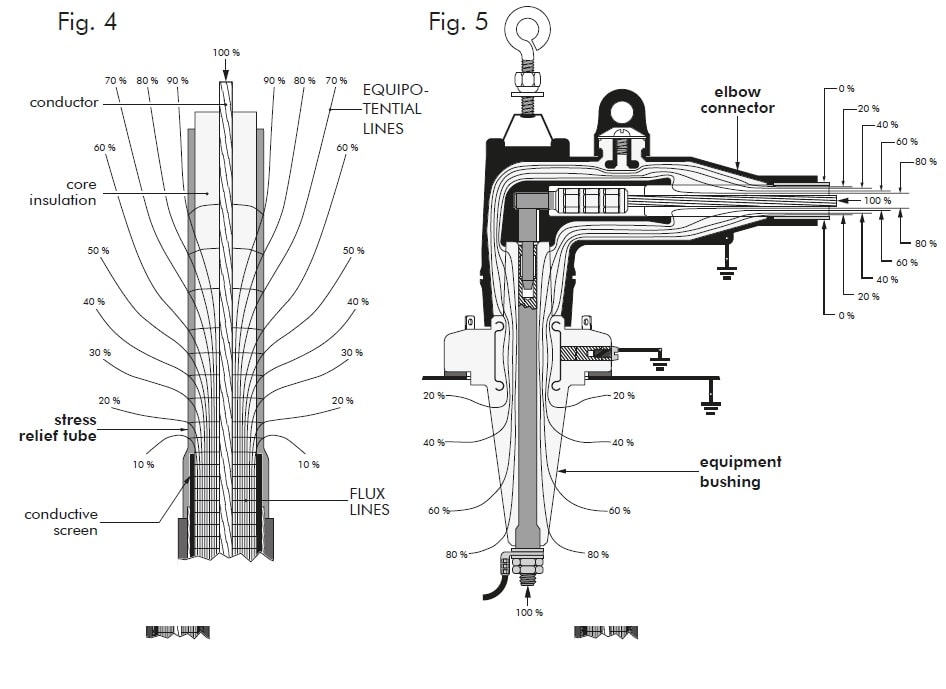

ELECTRICAL STRESS RELIEF

When the semi-conductive screen is cut, the electrical field distribution changes radically. The surrounding air and the dielectric material in the vicinity of the cut screen become overstressed (Fig. 2) and breakdown of the cable will soon occur. To avoid this, we control the equipotential lines by installing a termination with a stress cone (Fig. 3), a termination

with linear stress relief (Fig. 4) or a separable connector (Fig. 5) at the end of the screen.

The terminations will make sure that equipotential lines are sufficiently far apart when they finally emerge into the air and that they will not cause ionization. The separable connector keeps the equipotential lines inside the cable/connector assembly in a controlled way. This stress relief is automatically built into all the accessories by the precision moulding of conductive and/or insulating EPDM/silicone rubber.

Nexans Cable Accessories

Nexans manufactured Cable Accessories are in extensive service throughout the UK DNO power grid – the Euromold connectors are approved and are approved by several DNO/IDNO operators dependent on the product, voltage and network.

The JTS Joints and MONO Terminations are increasingly preferred and adopted by NERS Accredited Independent Connection Providers (ICPs) working on 11kV private networks.

Further Reading

-

Technical Information Euromold Connectors MV

Size: 1.20 MB

Technical Information Euromold Connectors MV

Size: 1.20 MB