EV Insulated Matting | Enhancing Safety in the Workplace | LV MV HV

Published 02 Jan 2024

Mitigating Risks | High Voltage Systems | CATU

EV Insulated Mats

Protecting against accidents in LV MV HV Systems

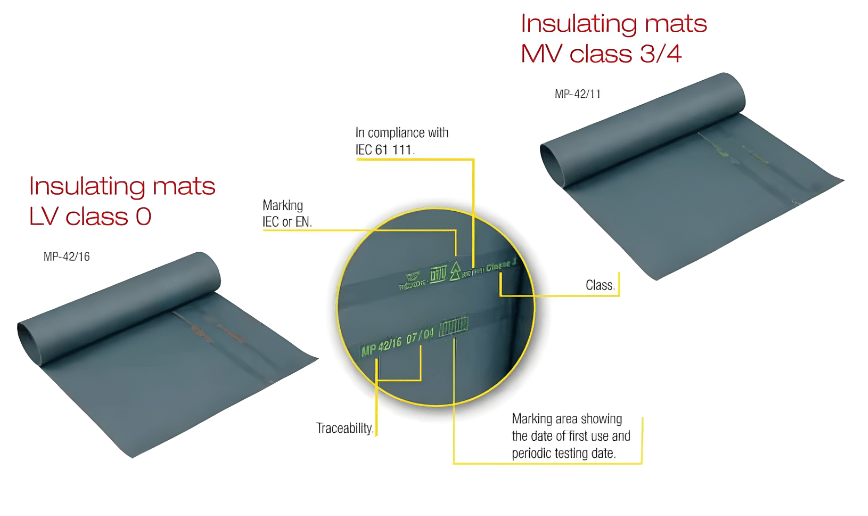

CATU’s electrical insulating matting provide electrical safety protection for individual and collective protection for workers involved on LV MV HV installations for voltages of 3.3kV, 6.6kV, 11kV, 15kV, 20kV and 33kV – generally used in conjunction with additional PPE such as insulating gloves for worker safety.

Insulated Mats, manufactured by CATU Electrical Safety and distributed by Thorne & Derrick, made from elastomer are used to cover ground for electrical protection of operators during work or interventions on electrical installations.

By incorporating insulated matting into safety protocols, the EV sector can enhance workplace safety, comply with industry standards and mitigating any risks associated with high voltage systems in electrical vehicles.

The mats are tested to IEC61111 and certification is provided upon request.

Insulating Matting | Thorne & Derrick hold the largest stocks in the UK of all types and Class of electrical matting for LV MV HV substations and switchgear applications to protect workers from protect people from hazardous electric shocks.

Purposes of using EV Insulated Matting

EV insulated matting is commonly used for a variety of reasons:

- Electrical Safety – Electric Vehicles (EV) operate with high voltage systems, preventing a risk of electrical shock during maintenance or repair.

- Preventing Grounding

- Compliance with Safety Standards

- Workplace Safety Practices

- Protecting against accidents

Meeting these specific standards is essential for creating a safe working environment and ensuring the well-being of technicians.

EV Insulated Mats | Compliance with IEC Standards

IEC61111 Standards

Insulated Mats, manufactured by CATU Electrical Safety and distributed by Thorne & Derrick from elastomer is used to cover ground for electrical protection of operators during work or interventions on electrical installations. By incorporating insulated matting into safety protocols, the EV sector can enhance workplace safety, comply with industry standards and mitigating any risks associated with high voltage systems in electrical vehicles.

The withstand test of insulating matting for electrical insulation is applied to each manufacturing batch of switchboard matting to ensure it does not have an electrical breakdown if exposed to high voltages – the working and withstand voltages must not be confused.

The proof test of insulating matting are dielectrical resistance tests provided by the mat manufacturer on the total running metre of the product and are used to safeguard a standard conformity of resistance throughout the entire section, roll or surface area of the electrical mat – the proof test must be applied to the insulating mats for a set time at a specified voltage level.

The information table below highlights and explains the IEC standard classification according to the maximum working voltages for rubber insulating matting.

| Class Of Insulating Matting According To IEC61111 | Proof Test | AC Maximum Working Voltage | Withstand Test Of Insulating Matting |

| Class 0 Matting | 5kV | 1000V – LV Low Voltage | 10kV |

| Class 1 Matting | 10kV | 7500V – MV Medium Voltage | 20kV |

| Class 2 Matting | 20kV | 17000V – MV Medium Voltage | 30kV |

| Class 3 Matting | 30kV | 26500V – MV Medium Voltage | 40kV |

| Class 4 Matting | 40kV | 36000V – HV High Voltage | 50kV |

High Voltage Electrical Safety

Further Reading

- Electrical Safety – Arc Flash Accidents & Electrocution In LV-HV Installations

- Arc Flash Calculation – Selecting Clothing & PPE To Protect Lives Against Arc Hazard

- IEC 61482-2:2018 – Get Up To Speed With The New Arc Flash Standard

- Arc Flash PPE | 7 Top Considerations

- Arc Flash The Basics

Insulating Matting | Voltage Detectors | Substation Kits | Phase Comparators

Arc Flash Clothing | Polo Shirts | Jackets | Coveralls | Trousers | Sweatshirts | Helmets

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

Thorne & Derrick stock and distribute a complete range of IEC61111 insulating matting for electrical safety, protection and working on low, medium and high voltage substations and switchgear up to 33kV – the IEC61111 standard provides a selection category for Low Voltage (1000V) to High Voltage (36kV).

Further Reading

-

Insulating Matting (LV MV HV Switchgear Mats)

Size: 233.96 KB

Insulating Matting (LV MV HV Switchgear Mats)

Size: 233.96 KB