Marconite Earthing – Conductive Concrete, Mixing & Use Of Marconite

Published 12 Nov 2018

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

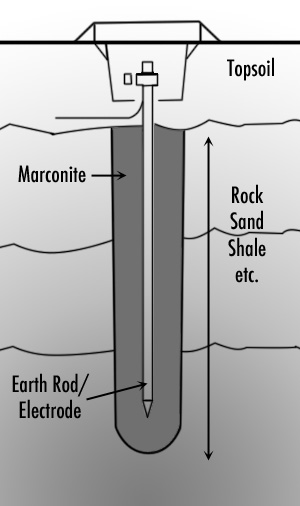

Marconite is the world’s leading premium electrically conductive backfill material which significantly enhances the effects of copper earth electrodes to reduce the resistance of a lightning protection or copper earthing system.

Marconite is a dark grey, granular material that replaces traditional sand and aggregate materials used within concrete mixes – it should be mixed in the ratio of 3 parts of Marconite to 1 part cement by weight with addition of 1 litre of water per 4kg of total mix:

Mixing Marconite

3 x 25 Kg bags of Marconite

1 x 25 Kg bag of Cement

25 litres (25 Kg) of Water

Ground enhancement materials such as Bentonite and Marconite earthing compounds are used to lower the resistance to earth of Earthing & Lightning Protection Systems – simple to install and used as backfill for earth electrodes, including earth rods or earth mats.

When mixed as described above, the Marconite forms a relatively dry material with an ‘as poured’ density of around 1300 Kg / m³ for earthing purposes.

The water content may be adjusted as the application requires, but this will affect the concretes final compressive strength and the drying times accordingly.

Typically Marconite concretes are touch dry within hours but can be several days before being fully cured.

Marconite is chemically inert with very low soluble sulphate content. It can be used with all conventional types of cement, as well as most proprietary resin-based cements, adhesives and gypsum plasters – due to the inert structure Marconite is non-corrosive to steel or copper and with a pH level in the neutral range will not degrade or erode cement structures.

Marconite Conductive Concrete is a registered product of the James Durrans Group and is solely produced by their subsidiary company Carbon International Limited.

Resistivity of Marconite

Marconite earthing aggregate provides exceptional resistivity with a resistance level of .001 ohm.m – even when mixed with cement the resulting resistance level is only 0.19 ohms.m.

Reducing Earth Electrode Resistance

Marconite is a conductive carbonaceous aggregate which, when mixed with conventional cement, has the effect of increasing the surface area of the earth electrode, thus helping to slightly lower its resistance. These earthing back-fill materials can provide a significant improvement to earthing system performance but also provide several secondary functions: maintain the resistance value at a more constant level throughout the year, to provide protection against 3rd party damage, or to protect the earthing electrode from corrosion.

Marconite is also useful for surrounding electrodes installed in rock.

Where a decision is taken to use FurseCEM, Bentonite, Marconite or any other special back-fill material, the design engineer should ensure that this information is passed to the construction staff – construction methods can be used to limit the amount used and therefore associated cost.

Examples are mixing Bentonite with local clay, reducing the hole diameter drilled (for vertical copper electrodes) and minimising the width and volume of the horizontal trench section into which the earth electrode will be installed.

Contact T&D for Copper Earthing Tapes – Bare Tape & Covered

Marconite – Electrically Conductive Aggregate Material

SUBSTATION EARTHING & MV HV CABLE JOINTING

To complement Earthing & Lightning Protection products we stock and distribute the most extensive range of copper earthing equipment.