Quad Cable Cleats – CMP Saturn QSDSS

Quad Cable Cleats – CMP Saturn QSDSS

CMP

Quad Cable Cleats

CMP Cable Cleats Saturn QSDSS

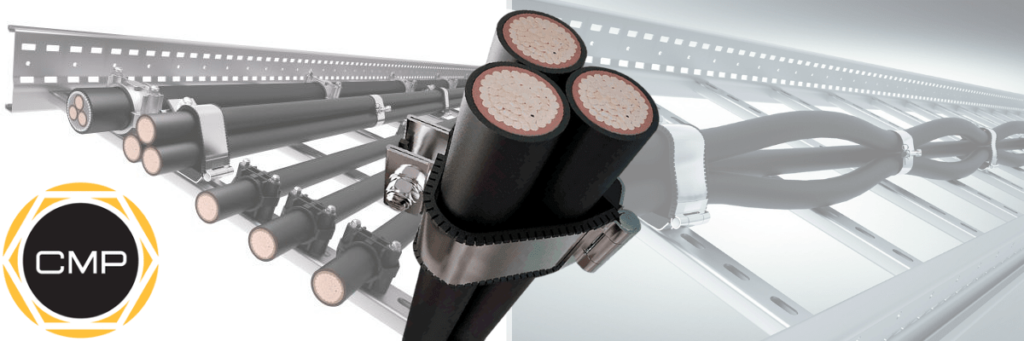

The Saturn quad cable cleats from CMP are metallic cable cleats which have been designed, constructed, and tested in accordance with the International Standard ‘Cable Cleats for Electrical Installations’ IEC 61914 to ensure the securing and retention of LV MV HV cables, without sustaining damage to the cable.

The range of cable cleats are made from 316L stainless steel, giving it high creep strength whilst providing excellent corrosion resistance in the harshest of environments. The Saturn cable cleats are designed for Quad application / formation.

The quad cable cleat manufactured by CMP have up to three M10 fixing clearance holes within one base allowing versatility to the installer during installation, and is designed to enable the product to be secured to a variety of mounting surfaces. The pre-formed cleat opens fully allowing the cables to be easily placed within the cable cleat to aid the installer before closing and securing via the mouth bolt.

Liners come as standard which help to restrain the cable(s) within vertical applications. Where thermal elongation of cables occurs, the liner also provides a layer of protection between the cable sheath and the cable cleat during normal operation. This additional layer protects the cable from chafing on any mounting surface due to differential movements such as those found in marine and offshore applications.

The liners also assist in the extra protection of cable(s) in the event of short circuit fault conditions. The standard liners supplied are classified as Low Smoke & Fume (LSF), Zero Halogen (LS0H) and Phosphorus Free.

➡ CMP Cable Cleats NEW | Quadruplex Cables & Quad Formation Cables

CMP Cable Cleats

Saturn QSDSS

Features

- Name Saturn

- Type QSDSS

- Third party certification to IEC 61914

- 316L stainless steel cable cleats

- For quad formation / application of cleating cables

- Short circuit rating of 152kA peak fault

- Operating temperature range -50°C to +60°C or -58°F to +140°F

- Liners are classified as Low Smoke & Fume (LSF),

- Zero Halogen (LS0H) and Phosphorus Free

- Combined single (M10) or 2 bolt (M10) fixing design

- More Cable Clamps | Trefoil | Aluminium | Stainless Steel | Cable Hangers

| CMP Cable Cleat Type | 6.1.3 Composite QSDSS – Standard Duty Stainless Steel |

| Design Specification | IEC 61914 |

| Temperature for Permanent Application | -50°C to +60°C IEC 61914 clause 6.2 |

| Needle Flame Test | Pass – 120 second flame application time IEC 61914 clause 10.0, 10.1, IEC 60695-11-5 |

| Lateral Load Test | Refer to CMP Products, IEC 61914 clause 9.3 |

| Axial Load Test | Refer to CMP Products, IEC 61914 clause 9.4 |

| Impact Resistance | Pass – Very heavy IEC 61914 clause 6.3, 6.3.5, 9.2 |

| Material | 316L Stainless Steel with Standard Liners Standard liners are classified as Low Smoke & Fume (LSF), Zero Halogen (LS0H) and Phosphorus Free |

Coatings are available upon request by adding the following suffixes to the ordering reference – EC for epoxy coating, PC for polyester coating and TC for thermoplastic coating.

Example order reference for epoxy coating suffix EC (QSDSS026031EC). Fasteners required to secure the cable cleat to the support structure are not included but can be supplied upon request/

Isolation/separation pads (to prevent corrosion between two dissimilar metals) are not included but can be supplied on request.

SHORT CIRCUIT TESTING TO IEC 61914 – CLAUSE 9.5

| Quad Formation of Cables | |||

| One short circuit 300mm fixed cleat centres |

Two short circuits 300mm fixed cleat centres |

Two short circuits 600mm fixed cleat centres |

One short circuit 300mm fixed cleat centres |

| 0.1 sec | 0.1 sec | 0.1 sec | 1 sec |

| 152kA Peak | 138kA Peak | 103kA Peak | 82kA Peak |

| 69.1kA r.m.s | 62.7kA r.m.s | 49.0kA r.m.s | 40.2kA r.m.s |

Saturn Quad Cable Cleats Technical Illustration

CMP Quad Cable Cleats

Product Selection Table

| Quad Cleat Part No. | Cable ∅ Range | Dimensions (MM) | Weight (g) | ||||

| W | H | D | Fixing Hole ∅ | ||||

| D1 | D2 | ||||||

| QSDSS019023 | 19-23 | 56 | 93 | 58 | 1 x M10 | – | 309 |

| QSDSS021027 | 21-27 | 64 | 101 | 58 | 1 x M10 | – | 334 |

| QSDSS026031 | 26-31 | 72 | 109 | 58 | 1 x M10 | – | 352 |

| QSDSS030034 | 30-34 | 78 | 115 | 58 | 1 x M10 | – | 364 |

| QSDSS033037 | 33-37 | 84 | 121 | 55 | 1 x M10 | 2 x M10 | 338 |

| QSDSS036040 | 36-40 | 90 | 127 | 55 | 1 x M10 | 2 x M10 | 349 |

| QSDSS039043 | 39-43 | 96 | 133 | 55 | 1 x M10 | 2 x M10 | 354 |

| QSDSS041045 | 41-45 | 100 | 137 | 55 | 1 x M10 | 2 x M10 | 366 |

| QSDSS044047 | 44-47 | 104 | 140 | 55 | 1 x M10 | 2 x M10 | 382 |

| QSDSS046051 | 46-51 | 110 | 147 | 55 | 1 x M10 | 2 x M10 | 429 |

| QSDSS049053 | 49-53 | 116 | 153 | 55 | 1 x M10 | 2 x M10 | 437 |

| QSDSS052056 | 52-56 | 122 | 159 | 55 | 1 x M10 | 2 x M10 | 452 |

| QSDSS055059 | 55-59 | 128 | 165 | 55 | 1 x M10 | 2 x M10 | 467 |

| QSDSS058062 | 58-62 | 134 | 171 | 55 | 1 x M10 | 2 x M10 | 479 |

| QSDSS061065 | 61-65 | 140 | 177 | 55 | 1 x M10 | 2 x M10 | 495 |

| QSDSS064068 | 64-68 | 146 | 183 | 55 | 1 x M10 | 2 x M10 | 512 |

| QSDSS067071 | 67-71 | 152 | 189 | 55 | 1 x M10 | 2 x M10 | 525 |

Cable Cleat Fitting Instructions

1. Place cable cleat on mount surface

2. Remove the nut, nut spacer and washer

3. Remove or insert booster pad as required

4. Secure cable cleat to mount surface

5. Lay cables in cleat

6. Close cable arms

7. Tighten mouth bolt nut