RISE NOFIRNO | DNV GL Approved Pipe Sealing Penetrations

Published 22 Sep 2020

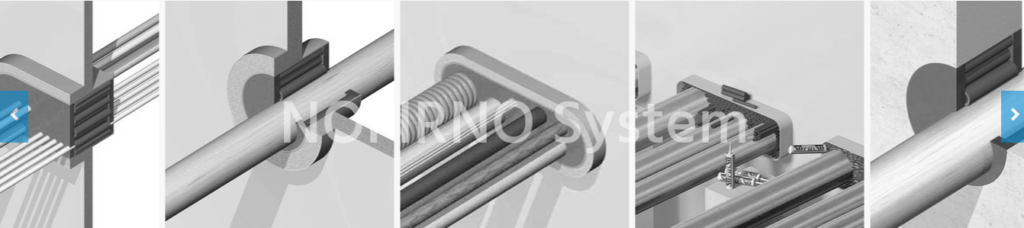

RISE NOFIRNO System

Pipe Sealing With DNV GL Approval

RISE NOFIRNO sleeves and sealant by CSD Systems are made from the highest grade silicone materials, and have a tested service life of over 20 years. Unlike some competitive systems, the RISE NOFIRNO system contains no cheap calcium silicate or mineral wool blankets, which can absorb moisture and cause corrosion of the penetration collar and pipes inside the collar. This problem is referred to as “Corrosion Under Insulation” (CUI).

The CSD NORFIRNO is a Single & Multi Pipe Penetration Sealing System composed of a steel sleeve (length 180 mm or 250 mm) welded or bolted to steel deck or bulkhead, NOFIRNO Filler Sleeves filling the open space between sleeve and pipe – one of the most adaptive systems for sealing straight and angled pipe penetrations and can even accommodate multiple pipe runs, significantly saving in space and weight.

The NOFIRNO system is Type Approved for the harshest ratings for A, H and Jet Fire Class, and is also approved for watertight, gas-tight, blast and shock applications.

RISE NOFIRNO System Features

- Approved for harshest fire ratings for pipe penetrations (EN, A, H and Jet Fire class)

- Allows substantial movement of the ducted pipes within the conduit

- High pressure ratings – designed for gas and/or watertight penetrations

- Prevents “Corrosion Under Insulation” (CUI)

- Longest service life and best Total Cost of Ownership of any sealing system

- NOFIRNO® rubber sleeves and sealant will remain stable and not be consumed by fire

- Approved for any combination of cable and/or metallic, GRP or plastic pipes

For insulated copper pipe penetration, RISE/ULTRA shell of thickness 2.5 mm shall cover the insulated pipes over a length of 210 mm.

For Multi-Mix Pipe, RISE/ULTRA strips/sleeves around the plastic pipes.

The penetration is sealed on both ends with a layer of 20 mm NOFIRNO Sealant.

Rise Nofirno Application/Limitation

Single pipe penetrations

- Approved for A-0 penetrations for steel, copper and GRP service pipes of following maximum sizes:

Steel: Ø408 mm; Copper. Ø420 mm; GRP: Ø408 mm.

See drawings Nos. R0207E Rev.2 and R0213E Rev.1.

- Approved A-0 to A-60 penetrations for insulated (Armaflex AF or equivalent) copper pipes of outside diameter up to Ø54 mm and for Insulated steel pipes up to Ø168 mm.

Maximum sleeve size: Max. Ø273 mm.

See drawings Nos. R0246E Rev.1, R0247E Rev.1, R0248E Rev.1 and R0249 Rev. 0.

Multi-pipe penetrations

- Approved A-0 to A-60 single and multi-pipe penetrations for steel/stainless steel pipes up to Ø408 mm, for Cu/CuNi pipes up to Ø420 mm and GRP pipes up to Ø408 mm. Maximum sleeve size: Max. allowable surface area: 2500 cm2 (500 mm x 500 mm).

See drawings Nos. N0009E Rev. 2 and N0011E Rev. 2 - Approved A-0 to A-60 single and multi-pipe penetrations for steel/stainless steel pipes up to Ø168 mm and for Cu/CuNi pipes up to Ø108 mm.

Maximum sleeve size: Max. allowable surface area: 3000 cm2 (1000 mm x 300 mm).

See drawings Nos. N0018E Rev. 2 and N0020E Rev. 1 - Approved A-0 multi-pipe penetrations for steel/stainless steel pipes up to Ø219 mm.

Maximum sleeve size: Max. allowable surface area: 1800 cm2 (600 mm x 300 mm).

See drawings Nos. N0045E dated 04.06.12

Multi-Mix pipe + cable penetrations

- Approved A-0 to A-60 penetrations for a mix of cables up to Ø105 mm (incl. CLX and LAN cables), steel/stainless steel pipes up to Ø168 mm, for Cu/CuNi pipes up to Ø108 mm and plastic pipes (PVC, PP, PPR, HDPE, PB, PVDF) up to Ø160 mm.

Maximum sleeve size: Max. allowable surface area: 3000cm2 (1000 mm x 300 mm). See drawing No. N0015E Rev.2, N0016E Rev.2 and N0017E Rev. 2.

The installation of the pipe penetration is to be in accordance with the manufacturer installation manual and referenced drawings.

For A-0 divisions, no insulation is needed on the sleeves and the pipes.

Approved for watertight penetrations up to a design pressure of 1.66 bar. Approved for airtight penetrations up to a design pressure of 1.00 bar.

The penetration system is generally not to be used for penetrating boundaries of tanks.

When pipe penetrations is requested to be used in watertight bulkheads on passenger ships and Special

Purpose Ships (SPS), the pipe penetration system has to comply with the requirements given in SOLAS (2009) Ch. II-1 Reg. 13.2.3 c.f. IMO Res. MSC.429(98) Reg. 13.2.3.4. Pipe penetrations passing through watertight bulkheads are subject for separate examination.

Each product is to be supplied with its manual for installation/application and maintenance.

NOFIRNO is one of BEELE Engineering’s ‘rapid cable and pipe sealing systems’ for use on board ships, on offshore pipework installations, in building and construction and other environments where the safety of people and installations has to be guaranteed.

Type Examination Documentation

- Test report No. R0209 dated July 2008 from Efectis Netderland BV (TNO).

- Test report No. R0325 dated July 2008 from Efectis Netderland BV (TNO).

- Test report No. R0556 dated July 2008 from Efectis Netderland BV (TNO).

- Test report No. 0303-010 dated 21 March 2003 from Beele Engineering.

- Test report No. 0501-039 dated 11 January 2005 from Beele Engineering.

- Test report No. 0609-056 dated 19 September 2006 from Beele Engineering.

- Test report No. 0712-060 dated 12 January 2007 from Beele Engineering.

- Test report No. 0702-061 dated 01 February 2007 from Beele Engineering.

- Test report No. 0704-067 dated 18 April 2008 from Beele Engineering.

- Test report No. 0706-070 dated 26 June 2008 from Beele Engineering.

- Test report No. 0805-080 dated 21 May 2008 from Beele Engineering.

- Test report No. 1206-104 dated 05 June 2012 from Beele Engineering.

Pressure test report No. 0203-D056 dated 01 March 2005 from Beele Engineering.

Tests Carried Out

Tested according to IMO FTPC Part 3 (IMO Resolution A.754 (18)) and in accordance with IMO 2010 FTP Code Ch. 8.

Marking of Product

The product or packing is to be marked with name and address of manufacturer, type designation, fire technical rating, MED Mark of Conformity and USCG marking if applicable.

NOFIRNO System By CSD

Further reading

- A60 H120 Pipework Fire Protection For Offshore Bulkheads & Decks

- NOFIRNO – Cable & Pipe Sealing Systems

- NOFIRNO Sealant | Sealing For Cable & Pipes 2 Hour Jet Fire Tested

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV