Euromold | 66kV Joints Connectors Terminations Surge Arresters

Thorne & Derrick are leading specialist distributors of MV HV Joints, Terminations & Connectors for use on 11kV/33kV/66kV cable networks – sadly cable failures are increasingly common on onshore and offshore medium/high voltage cable networks.

A toxic cocktail of unskilled labour which is untrained in both basic cable preparation and tool use is usually the cause – this lethal combination unleashes devastation on clients assets nevermind the incalculable cost of downtime associated with power outages.

This investigation and report explains the causes into why the below 66kV cable joints failed by dissecting the cable joints one by one and recording findings to what could have caused the cable failings.

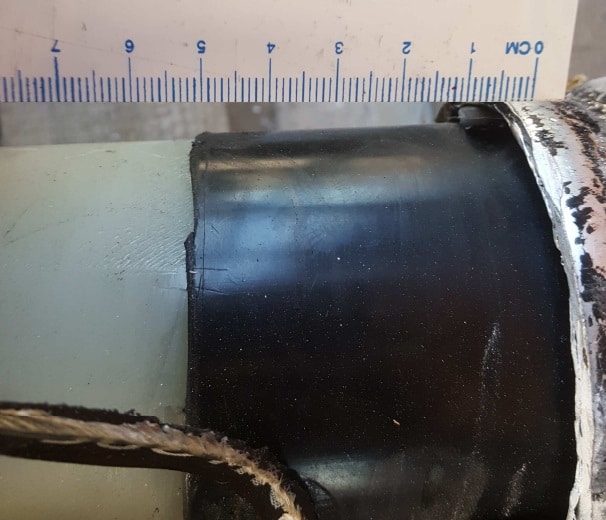

Severe cable joint failure with cable faulted to destruction – caused by a combination of cable preparation failures and factors.

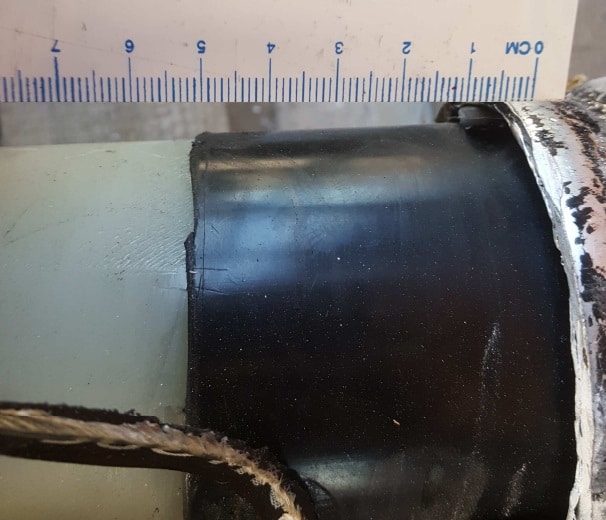

Comparing dimensions from the screen cut length to the corrugated aluminium cut shows the 66kV cable failure occured at the end of the semicon screen cut.

Failure occurred at the end of the semicon screen cut on the high voltage power cable.

Specialist cable jointing tools to effectively prepare and remove semicon screens on 11kV/33kV and 66kV power cables should always be used by jointers – cable jointers should be trained and competent to install manufacturers products.

Poor heat shrinking technique by the cable jointer with non-uniform wall thickness on this heat shrink insulation tube

Conclusion

The cable joint failure was caused by the poor removal of the semi-conductive and the very bad XLPE insulation preparation. Deep and dirty cuts and burrs can seen in the insulation causing the XLPE insulation to be over stressed and this was what ultimately caused the insulation failure.

All HV cable joints and accessories should only be installed by trained professionals with all the correct accreditation. Any other terminations that have been installed by the above ‘jointer’ should be checked and replaced immediately.

Cold Shrink

3M pioneered the development of Cold Shrink technology for use as a material for the jointing, termination and connection of medium/high voltage cables. Since then cold shrink has been adopted by global utilities as a user-friendly and reliable MV-HV cable accessory range with high performance, stable life cycle and minimal joint or termination failure rates.

Should you require any support with the specification or supply of MV HV joints, terminations or connectors for use on 11kV/33kV/66kV energy networks please do not hesitate to contact us.

Cold Shrink Reliability Low Failure Rates

0.067% Cold Shrink Cable Joints/Splices

0.022% Cold Shrink Cable Terminations

*Data based upon U.S. failure data of U.S. manufactured 3M Cold Shrink Medium & High Voltage Cable Accessories between 2009 and 2012.

Thorne & Derrick

THORNE & DERRICK are national distributors LV, MV & HV Cable Installation, Jointing, Substation Earthing & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Invitation

Thorne & Derrick invite you to join LinkedIn’s largest LV-HV Electrical Discussion Group : Low & High Voltage Power, Cabling, Jointing & Electricals. Discussion subjects include cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV. Network, engage and promote your profile, company or products with over 10,000 influencers.

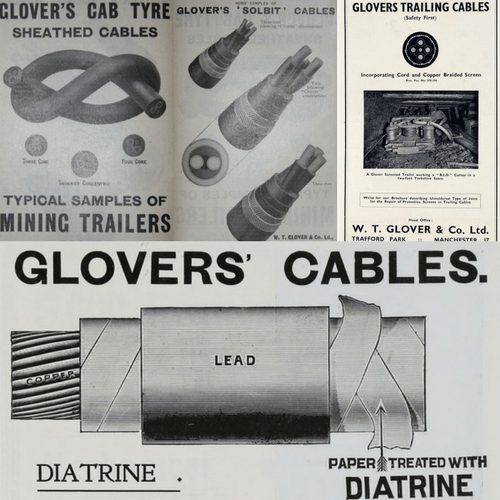

- Application: 66kV Cable Joint High Voltage

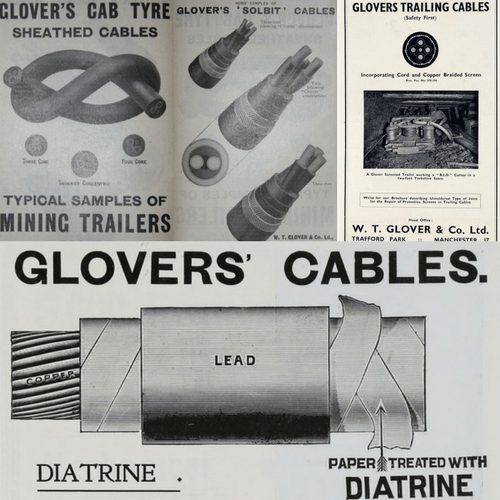

- Cable Joint Type: 66kV 3 Core Glovers Gas (HP) Cable Joint

- Contributor: Matthew Taffs EHV Cable Jointer & Director at CRS (Cable Repair Services) Ltd

- Featured Manufacturer: Glovers (W T Glover)

- Client: SSE

- Sector: Utility

66kV Cables

Gas Filled High Voltage Cable Jointing

The 66kV 3 core high pressure (200 psi) gas joint (nitrogen) was made for SSE by Matthew Taffs of CRS Ltd and John Beck both working for Balfour Beatty at the time.

The 66kV cable construction was oval copper conductor with a lead sheath and steel reinforcing tapes with hessian wrapped layer. The manufacturer of the cable joint was Glovers (W T Glover) of Trafford Park, Manchester which later became part of BICC.

The cable joint is from the 1950’s and when the joint was unpacked from the wooden create it was still packed in straw. The insulation of the cable had to be stepped down to the conductor known as pencilling using piano wire and weights.

The joint consisted of a two piece split ferrules which was sweated on the conductor with tinmans metal. Once sweated the ferrule was cleaned up and the insulation was ready to be applied. The insulation was flat/plain paper tapes (not crepe) coated in a thin layer of grease and was applied with care by the jointer. Once built up to the final diameter the end profiles had to be skilfully teared down using piano wire and weights again. The metallic screen reinstated from one side to the other and then each core is covered in terylene tape.

Both end cable glands of the joint had internal plumbs /wipes and when the plumbing was finished – hot oil was poured on followed by a hot metal into the cable gland to reinforce the steel tapes and lead sheath as this 66kV cabling system is such high pressure it would split the lead sheath.

Once the 66kV joint was finished the jointer bolted the sleeve to the cable gland and turn on the nitrogen gas and check for leaks. The 66kV joint could be protected in either a Glo (Glovers) Sleeve filled with compound/ bitumen or heat shrink. The job was project managed by Gary Horne, now of CRS (Cable Repair Services) Ltd.

66kV 3 Core Glovers Gas (HP) Cable Joint

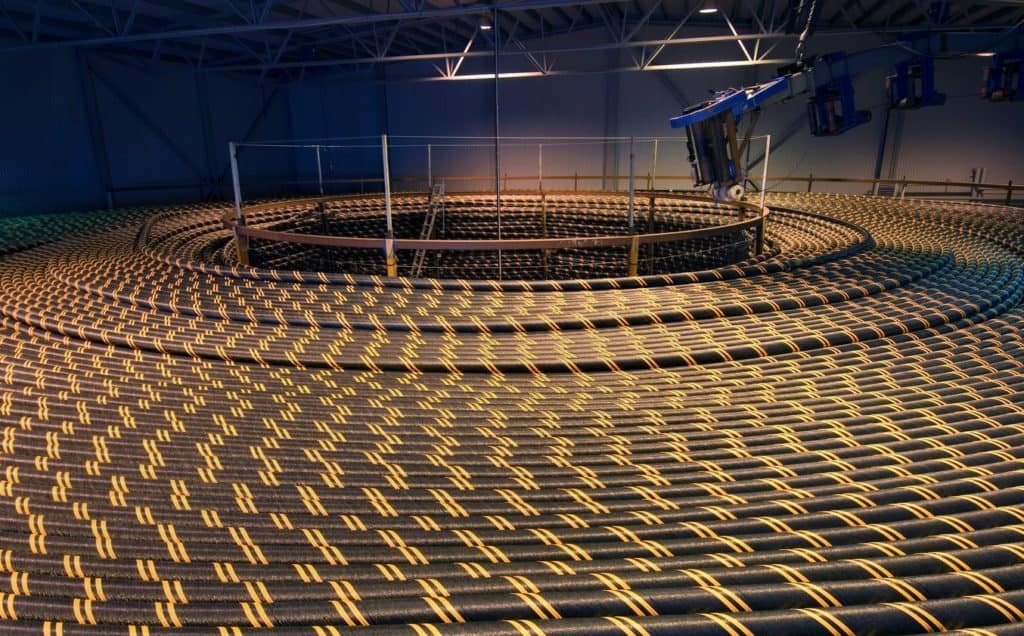

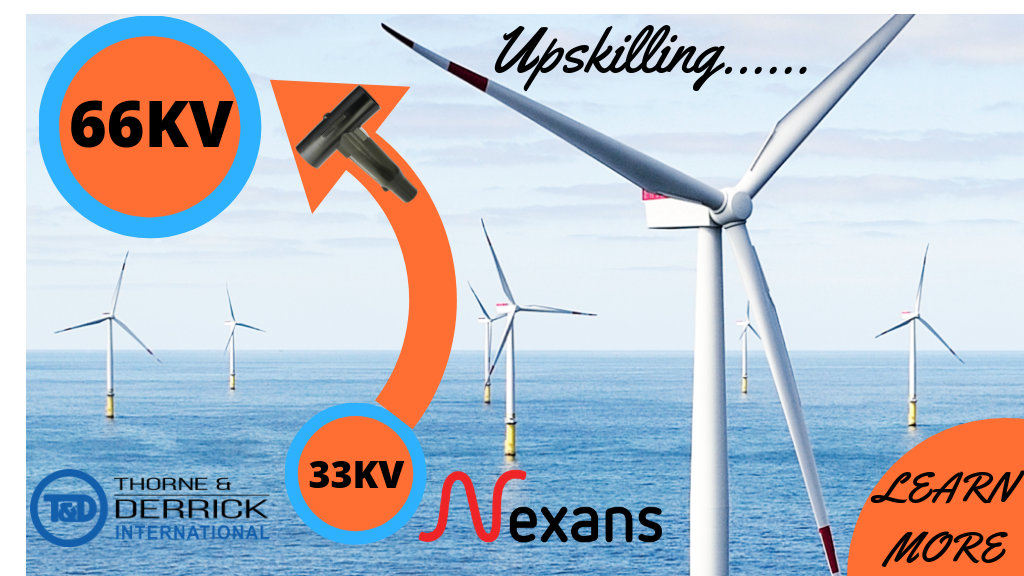

66kV Polymeric Cables

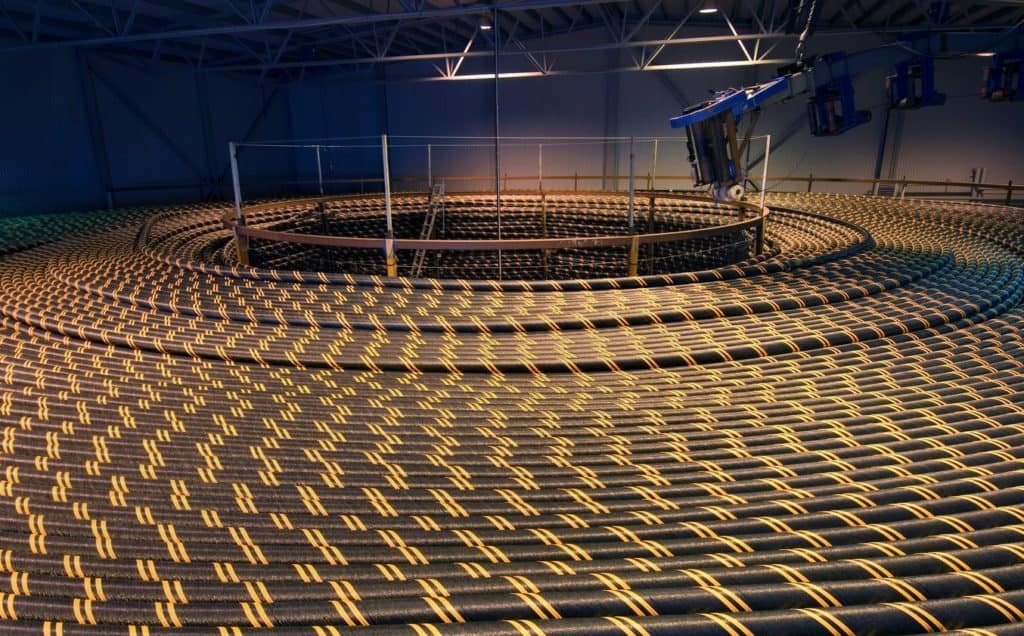

21st century cable manufacturing is dominated by polymeric type insulated cables and for offshore wind farm power generation including subsea power, array, inter-array and intra-array cables – to support this type of 66kV high voltage cable infrastructure Thorne & Derrick via their distribution agreement with Nexans can supply a complete range of joints, terminations, connectors and surge arresters detailed below.

Ad: Two Times More Power. Jointers! Empower your CV and skill-set by grasping the 66kV Jointer Training opportunity. Jointers must currently be 33kV Competent and experienced to be ready to undertake the step-up to 66kV from 33kV.

Pictured: Prysmian type tested a 3-core 66kV EPR insulated “wet-design” cable system with aluminium conductor (copper is also available) – and integrated optical element. The solution includes factory, field cable joints, plug-in cable terminations and cable cleats, using proprietary Prysmian Click-Fit™ technology combinings the use of EPR insulation.

66kV Cables – Offshore Wind Farms

Company History – Walter T. Glover & Co

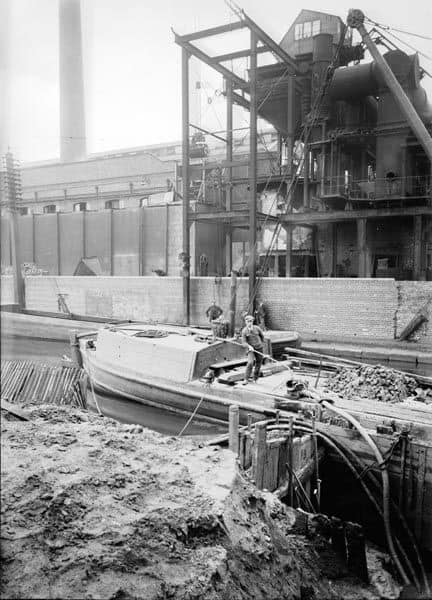

Walter T. Glover & Co of Trafford Park, Manchester and London, were electrical cable manufacturers.

1868 – Company founded with premises at the Bridgewater Street Iron Works in Salford. The founder, Walter T. Glover, was a commercial machinery agent for the Lancashire cotton industry.

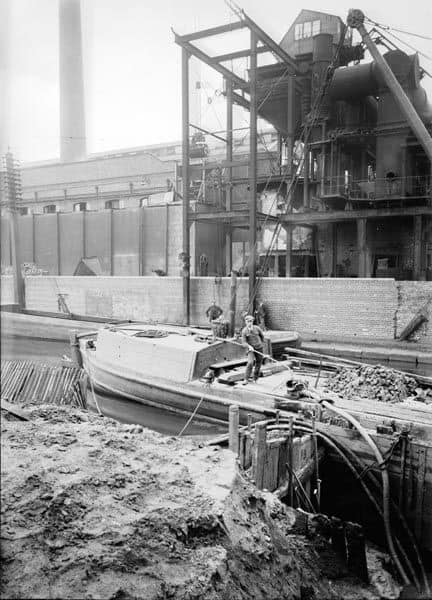

1959 – BICC acquired 50% of Submarine Cables Ltd which was used to manufacture and install power cables. Glover’s submarine cables were used to link England and France, and the north and south islands of New Zealand. However, although the company appeared to be doing well, there was increasing international competition to supply cables. The south side of the Trafford Parks works was integrated into the newly formed Wiring and General Cables Division of British Insulated Cables (BICC).

Trip down memory lane…………….

W.T. Glover, Trafford Park, cable being laid over a cofferdam, 1911

W.T. Glover, Trafford Park, Installation of cabling in Ebbw Vale, 1905

W.T. Glover, Trafford Park, installation of cabling, with motor vehicle clearly visible, 1905

W. T. Glover and Co – 1970 The Trafford Park factory was closed, but the Glover brand continued as part of BICC.

Thorne & Derrick Specialist Electrical Distributor

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Installation & Cable Pulling Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Copper Earth Tapes, Electrical Safety, Cable Glands, Arc Flash Clothing Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

More…

T&D’s Power Blog covers: LV MV HV & EHV Transmission & Distribution, Substations, Switchgear, Cable Jointing & Termination, Cable Fault & Repair, Underground Cables

➡ Visit Power Blog