Transformer Bunds | Bunds for oil-filled transformers manufactured from steelwork on reduced lead time and at competitive prices from Thorne & Derrick | Contact us with your requirements | Stock, Service & Product Support

How Can We Help?

Thorne & Derrick can provide design and manufacturing services for Transformer Bunds with optional oil filters, drain valves, filter systems and ancillaries in both mild and galvanised steel (painted or unpainted) – innovative, efficient, safe and cost-effective solution for protection against leakages of insulating liquid to BS EN 61936-1:2010.

BS EN 61936-1:2010

Power Installations Exceeding 1kV a.c. Common Rules

Oil Filled Transformers

Guest Contribution: Carl A. Watkin IMEMME (Hons) I.Eng MIMMM MIET AIOSH

Carl has over 40 years experience as a Projects Director, Electrical Engineer & Project Manager in the highly regulated HSE HID hazardous and heavy industry sectors – this includes global ATEX and IECEx hazardous environment and area industries, civil tunnelling, LV MV HV utility sectors and the renewables sector.

In this original post from LinkedIn, the business and employment-oriented social media network, Carl discusses transformer bunds with gathered opinions from industry peers featured in the thread of comments below.

Bunding – Oil Filled Transformers

To Bund or Not To Bund?

by Carl A. Watkin

Question to all my fine Engineering contacts regarding oil filled distribution transformers – transformers are exempt from the UK oil storage regulations, as they are oil using (cooling) rather than storing, unless they have a conservator, holding in excess of 201lts, connected by single pipe – I see many transformer installs, including DNO installations, that do not have bunds around the transformers.

See: BundGuards | Substation & Transformer Oil Spills & Leaks Containment

What are your thoughts on bunding, or not, of oil filled transformers? What criteria would you use to assess whether to bund, or not?

➡ Neil Denbow (Director at Eden Transformer Oil). For distribution transformers yes you can but the process should be carried out by an accredited MIDEL Service Partner (we were the first). For power transformers yes but with referral to M&I Materials. There have been many successful retrofills around the world – MIDEL 7131

Contact Applied Power Engineering

➡ Manuel Bolotinha (Electrical Engineer). Usually sealed distribution transformers up to 630-800 kVA don’t need to be bunded.

➡ Neil Denbow (Director at Eden Transformer Oil). Manuel, BS EN 61936-1:2010 doesn’t differentiate between breathing and hermetically sealed transformers, it is defined by the volume of oil in the transformer.

➡ (Richard Emery IEng MIET MIHEEM Authorising Engineer (E) IHEEM AE(E) at Green Building Design Consultants). I get the transformer bunding problem, and even if you don’t have an oil storage problem, and the environment agency have incorrect information there is the risk assessment? Is a spillage going to cause secondary contamination, disruption and damage? How do we deal with external transformers/ bunding and rain water? I have seen some bunded walls with 300mm of water in them others with drain taps left on.

➡ Neil Denbow (Director at Eden Transformer Oil). Richard, larger 11kV transformers will have oil/water separation systems, smaller transformers will have valve with a oil/water capture filter that allows water to pass through but trap oil. We sell the latter on our website www.edenoil.co.uk and have a partner for the lager systems:- When a bund has not been maintained or doesn’t have filter system, we offer a bund emptying service.

➡ Dan James Technical Services Engineer (HV Senior Authorised Person at NG Bailey). We’ve put in from full on concrete swimming pools, active filters to perspex shields around the rads to stop fluid spraying past the bund. Most of the time midel is used these days which doesn’t have the same environmental issues, a bund with a filter seems to be what we do most though.

➡ Neil Denbow (Director at Eden Transformer Oil). Dan, you are right that MIDEL is readily biodegradable but BS EN 61936-1:2010 doesn’t differentiate between oil, synthetic or natural esters. However, insurance companies do.

➡ Craig Davies Senior Electrical Engineer – (Navitas Engineering Ltd) This has been debated many times in the Rail industry. With respect to Environmental Agency website error, certain parties in Rail industry have received same letter from Environmental Agency but certain representatives contradict each other in their response.

➡ Derrick Stableford P.Tech.(Eng.) (Electrical, Instrumentation and Controls Designer at Associated Engineering). Funny I had a containment question at work this week. Sorbweb matting would be my answer for leak control. Most trannys at this level have level switches as options, the hard part is the comms back to the control centre, without creating a cyber security intrusion risk. The sorbweb Mat adsorbs oil, and repels water. No need for a shed. Using food grade oil will also help with environmental risks. You could fry your lunch with a drawn off sample, or bang it in your diesel. The bunding and double wall systems have their own cost adders and maintenance issues, Inc water pump outs and disposal. Mechanical separators can freeze and fail, esp. here at severely minus temps.

➡ Craig Davies Senior Electrical Engineer – (Navitas Engineering Ltd). Thank you and I’ll have to research sorbweb matting.

Contact Applied Power Engineering

➡ Tony Haggis Director (Tony Haggis Consulting Ltd). Hazard control should follow the hierarchy: 1. Eliminate the hazard 2. Reduce the hazard 3. Control the hazard 4. PPE.

Pole transformers are not ‘reasonably practicable” to protect using HV fuses, particularly for LV side faults. Effective bunding is impossible. The most difficult zone is the tails from transformer to LV fuses. UK DNOs generally use double insulated single core cables fitted with plastic cleats and fixed to a wooden pole. LV fuses are single phase plastic units seperated 300mm apart, again, fixed to a wood pole. Phase to phase and earth faults are virtually impossible. Lightning takes out a lot of pole transformers causing them to explode oil over an area greater than any bund could catch. Again, the root cause is now well understood. A lightning induced flash over on the HV bushing causes the transformer tank to rise to more than 50kV. However, the LV winding is earthed separately from the HV earth and so the tank back flashes to the LV windings which fails resulting in a permanent LV side fault and transformer burnout. A simple 6kV lightning arrester fitted between the LV neutral and tank combined with a specified LV BIL (Basic Impulse Level) of 30 kV eliminates the problem. Also attention to LV fuse sizes and LV network look impedance significantly reduces burnouts due to uncleared LV faults.

➡ Karl R (Functional Safety & Systems Engineer). Watch out for an error in the HSE publicised “Hierarchy of Controls” leaflet. The vitally important area of physical isolation was missed. The hierarchy is actually: 1 Eliminate – do it a different way that doesn’t use the hazardous methods or substances. There’s no risk if there’s no hazard. No need to mitigate for a non existent hazard. Save effort, money and time for use elsewhere. 2 Substitute – use something non/less hazardous 3 Isolation – Physical separation. Barriers, bunds, locked areas and vessel containment. Dual layers. 4 Design – Automation, control, monitor, report and safely shutdown/reroute. Engineered solutions to mitigate hazardous situations and prevent hazardous material release. Control and safety systems to look after the process. Switchgear protection. 5 Admin – Enforcement and training. Emergency Response Procedures. Authorised areas, Competency, Risk Assessments, Design Reviews, Method Statements, verification and validation, maintenance, etc. 6 PPE

➡ Dale Smallshaw Managing Director (CRITICAL ELECTRICAL SOLUTIONS LIMITED) There’s a regulation in the 18th edition where it covers transformers containing oil shall be bunded or pitted to distinguish any potential fires

Transformer Bunds | Bunds for oil-filled transformers manufactured from steelwork on reduced lead time and at competitive prices from Thorne & Derrick | Contact us with your requirements | Stock, Service & Product Support

How Can We Help?

Thorne & Derrick can provide design and manufacturing services for Transformer Bunds with optional oil filters, drain valves, filter systems and ancillaries in both mild and galvanised steel (painted or unpainted) – innovative, efficient, safe and cost-effective solution for protection against leakages of insulating liquid to BS EN 61936-1:2010.

Sealing Transformer Bunds (TX) | Failure to correctly and effectively seal cable ducts with a compliant system can inflict catastrophic damage to LV-HV electrical distribution networks, substations and power supply. View below our complete ranges of Duct Sealing Products including cable transits to provide a watertight seal and defence against flood damage to low, medium and high voltage cable ducts with additional protection against harmful flammable gas migration and fire spread.

BS EN 61936-1:2010

Power Installations Exceeding 1kV a.c. Common Rules

The following information and clauses concerning transformer bunds is extracted from BS EN 61936-1 : 2010.

Transformer Bunds

8.8 Protection Against Leakage of Insulating Liquid & SF6 Gas

8.8.1 Insulating Liquid Leakage & Subsoil Water Protection

8.8.1.1 General

Measures shall be taken to contain any leakage from liquid-immersed equipment so as to prevent environmental damage. National and/or local regulations may specify the minimum quantity of liquid contained in an equipment for which containment is required. As a guideline, where no national and/or local regulations exist, containment should be provided around liquid immersed equipment containing more than 1,000 litres (according to IEEE 980: 2,500litres).

8.8.1.2 Containment for indoor equipment

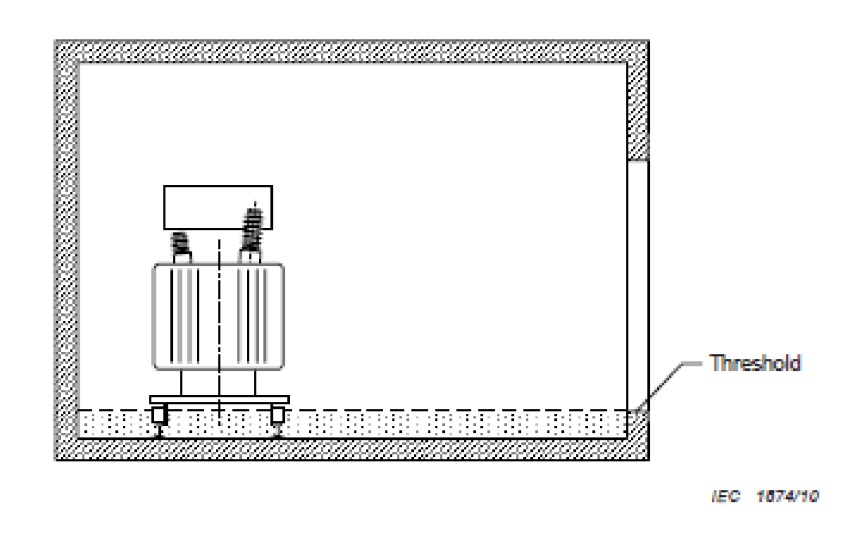

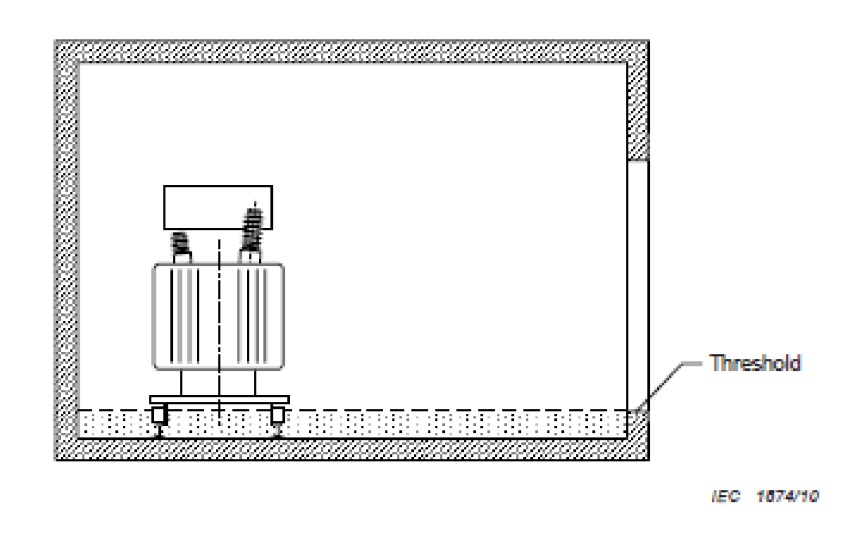

In indoor installations, spills of insulating liquid or transformer oils may be contained by providing impermeable floors with thresholds around the area where the equipment is located or by collecting the spilled liquid in a designated holding area in the building (see Figure 11).

The volume of the insulating liquid in the equipment as well as any volume of water discharging from a fire protection system shall be considered when selecting height of threshold or volume of the holding area.

8.8.1.3 Containment for outdoor equipment

The quantity of insulating liquid in equipment, the volume of water from rain and fire protection systems, the proximity to water courses and soil conditions shall be considered in the selection of a containment system.

NOTE 1: Containments (sumps) around liquid immersed equipment, including 11kV transformers, and/or holding tanks (catchment tanks) are extensively used to prevent escape into the environment of insulating liquid from equipment.

Containments and holding tanks, where provided, may be designed and arranged as follows:

tanks;

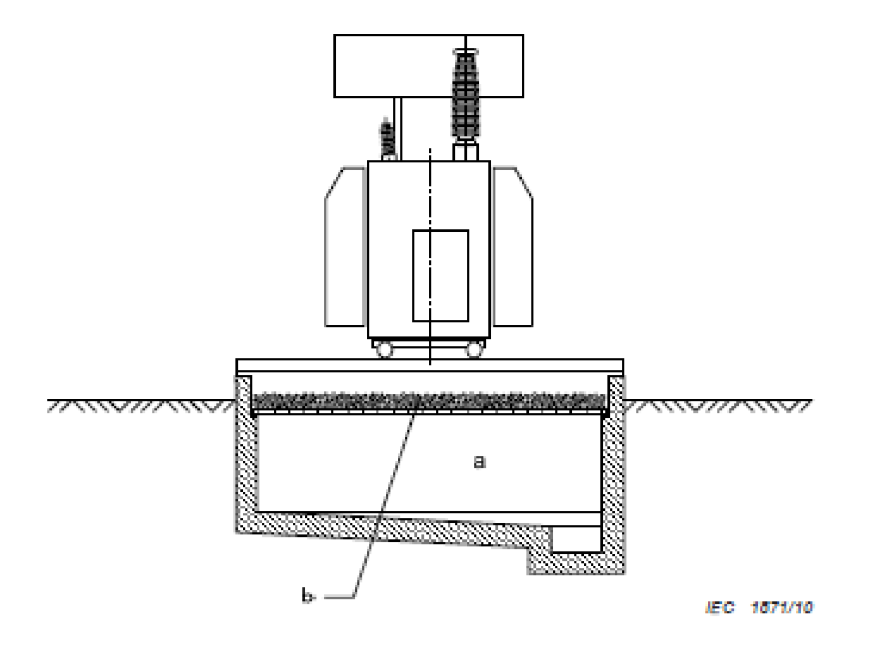

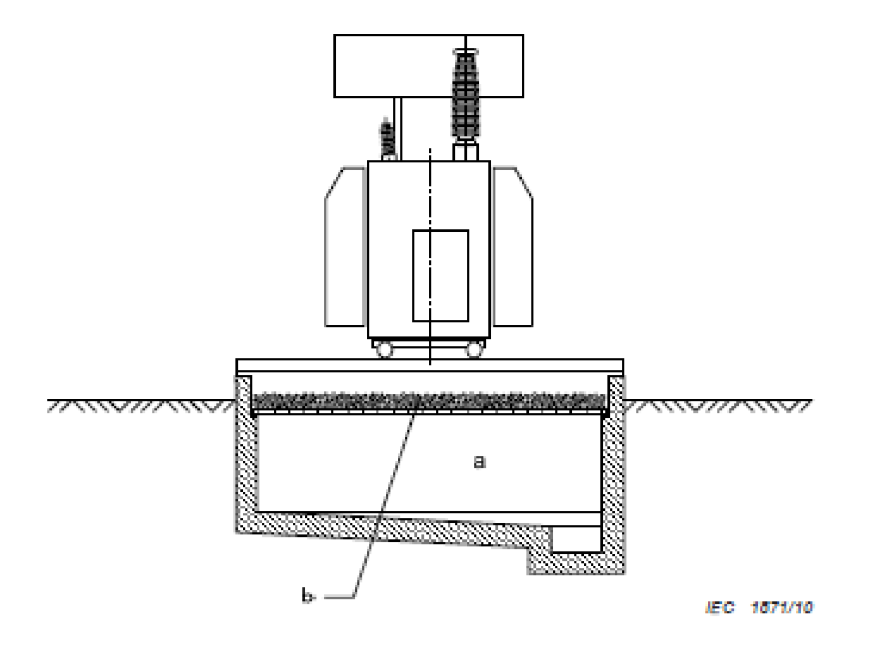

sump with integrated catchment tank for the entire quantity of fluid (Figure 8);

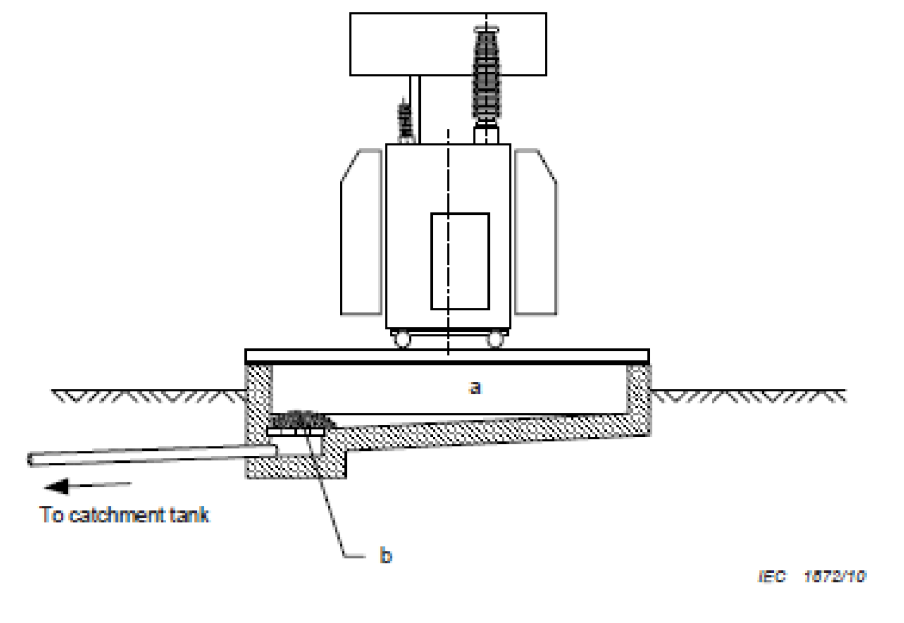

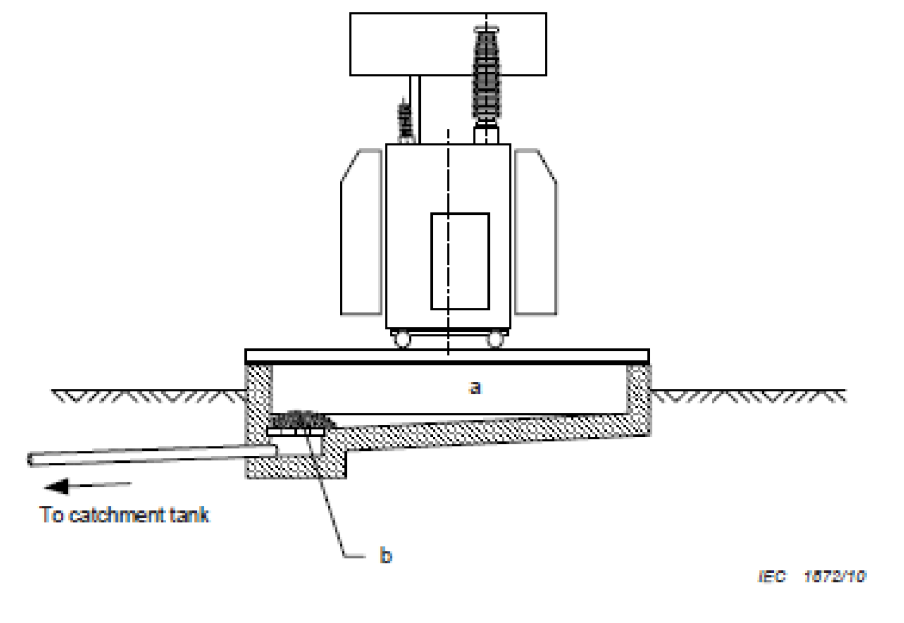

sump with separate catchment tank. Where there are several sumps, the drain pipes may lead to a common catchment tank; this common catchment tank shall then be capable of holding the fluids of the largest transformer (Figure 9);

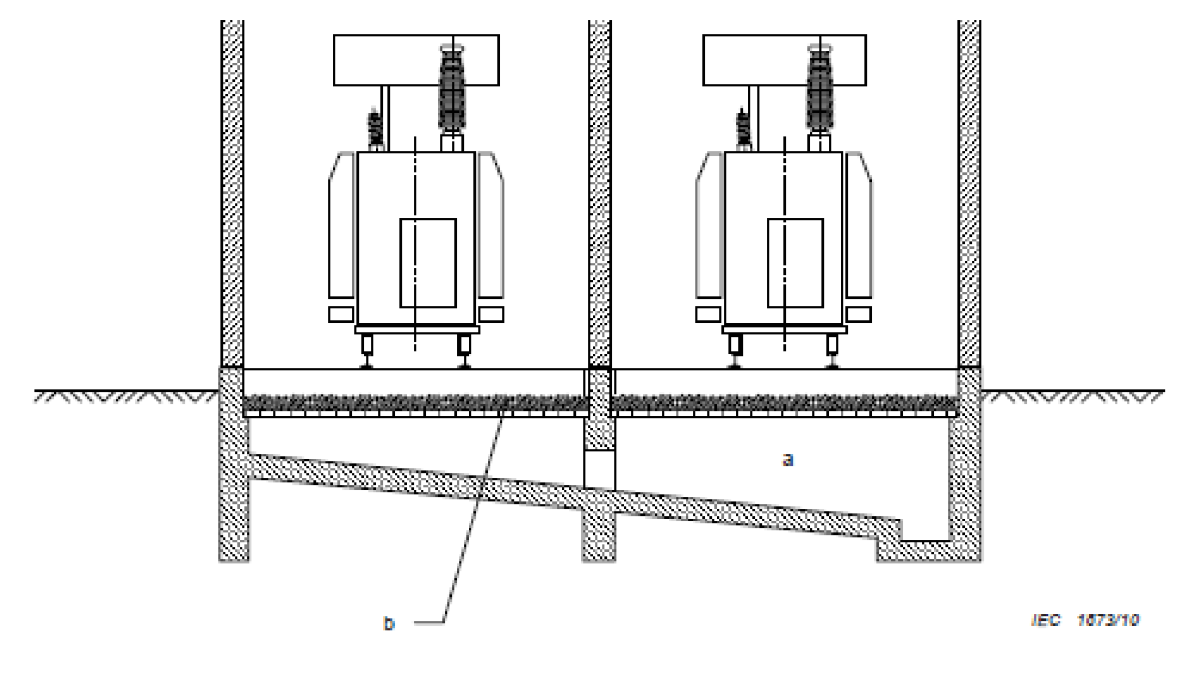

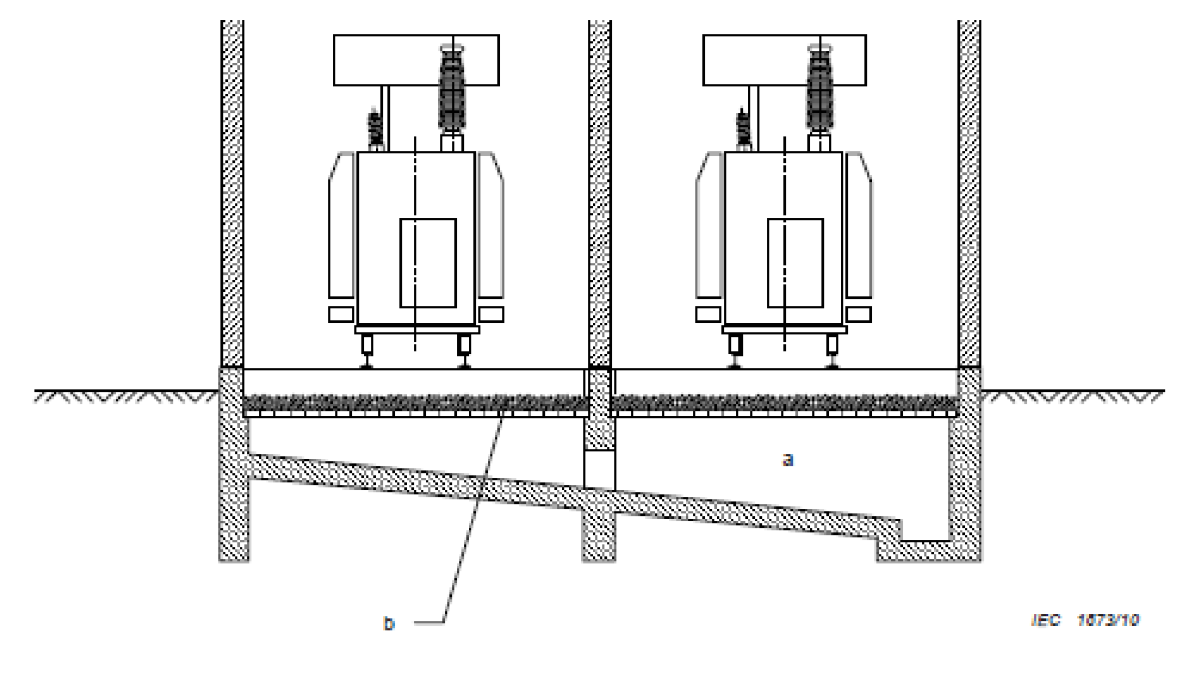

sump with integrated common catchment tank for several transformers, capable of holding the fluids of the largest transformer (Figure 10).

The walls and the associated pipings of sumps and catchment tanks shall be impermeable to liquid. The capacity of the sumps/catchment tanks for insulating and cooling fluids shall not be unduly reduced by water flowing in. It shall be possible to drain or to draw off the water.

Transformer Bund

A simple device indicating the level of liquid is recommended.

Attention shall be paid to the danger of frost.

The following additional measures shall be taken for protection of waterways and of ground water:

the egress of insulating and cooling fluid from the sump/tank/floor arrangement shall be prevented (for exceptions, see 8.8.1.1);

drained water should pass through devices for separating the fluids; for this purpose, their specific weights shall be taken into account.

NOTE 2: For outdoor installations, CIGRE Report 23-07 [30] recommends that the length and width of the sump is equal to the length and the width of the transformers plus 20 % of the transformer’s height (including the conservator) on each side. IEEE 980 recommends that spill containment extends a minimum 1,500 mm beyond any liquid-filled part of the equipment.

♦ IEEE 980-2013 – IEEE Guide for Containment and Control of Oil Spills in Substations.

NOTE 3: Examples for the automatic draining of water and separating of liquids is given in CIGRE Report 23-07 and IEEE 980.

State and regional laws and regulations shall be taken into account.

Figure 8 – Sump With Integrated Catchment Tank

Key

a) Containment: the entire quantity of fluid of the transformer plus rain water

b) Gravel layer for fire protection see B.7-2

NOTE : In addition, the water from the fire-extinguishing installation arty) should be considered.

Figure 9 – Sump With Separate Catchment Tank

Key

a) Containment: minimum 20 % of the fluid from the transformer

b) Gravel layer for fire protection see B.7-2

Figure 10 — Sump With Integrated Common Catchment Tank

Key

a) Containment outdoor: the entire quantity of fluid of the largest transformer plus rain water Containment indoor the entire quantity of fluid of the largest transformer

b) Gravel layer for fire protection see 8.7.2

NOTE: In addition, the water from the fire-extinguishing installation if any should be considered.

Figure 11 – Example For Small Transformers Without Gravel Layer & Catchment Tank

NOTE : The dotted area denotes the volume of the entire quantity of insulating fluid of the transformer spilled on the floor.

Further Reading

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

The 11kV Specialists

Thorne & Derrick distribute the most extensive range of 11kV Cable Jointing, Terminating, Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at 11kV and up to and EHV transmission and distribution voltages.

- Key 11kV Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M Cold Shrink, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Panduit, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

➡ James Hoare (LHW Partnership – Electrical & Energy Engineers). I thought the only way to get round was outdoor enclosure with class C or cast resin – when cast resin were first coming in they were welcome in buildings as an alternative to MIDEL as no need to bund the transformer.

➡ Neil Denbow (Director at Eden Transformer Oil). James, Class K insulating liquids such as the MIDEL range have the higher fire protection and are also readily biodegradable (unlike oil). However BS EN 61936-1:2010 doesn’t distinguish between the different liquids. By the way, as MIDEL Service Partners, we offer a mineral oil to MIDEL 7131 retrofill service. Click here for more information.

➡ James Hoare (LHW Partnership – Electrical & Energy Engineers). Neil – thank you – I used to work for GEC many …moons ago and we used to make distribution transformers dry and liquid – in those days Midel was a GEC group company so know it well . GEC became Alstom and think it’s now Schneider at this volts !!!

➡ Carl A. Watkin Neil, can you directly replace oil with MIDEL, one for one? I was told by Schneider that retrofit would involve fitting larger rads to the transformer as the volume of Midel required, per transformer KVA unit, to achieve the same cooling properties was higher?