The Solution to Resin Type Hang-Off Removal From Cables

Published 24 Feb 2025

Resin Type Hang-Off Removal | Case Study Credit: Mark Kinder at Kintech Energy

Can You Remove A Resin Type Hang-Off After The Resin Has Cured?

After discovering damage to a power cable or identifying that it has reached the end of its operational life, it may require removing Resin Type Hang-Off before the cable can be replaced. The question is, is Resin Type Hang-Off Removal possible after the resin has cured, without offshore expenses and time consumption becoming extreme? The following Resin Type Hang-Off Removal case studies explore the complexities of removal from a LV MV HV offshore marine cable and why Resin Free Hang-Off (RFHO) solutions by Kintech Energy are essential to avoid these barriers in future projects.

Resin Type Hang-Off Removal Case Studies

Case Study #1

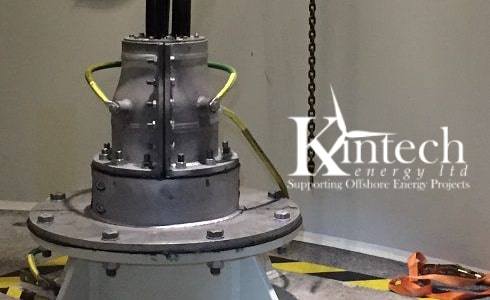

Several cables had to be removed and replaced shortly after installation, but the problem was discovered after the resin in the hang-off had cured. A dive team were mobilised to cut the cable at the exit of the CPS, then the entire hang-off was detached from the TP flange and lifted.

The cable and hang-off had to be held in position above the TP flange and the power cable, cut into short sections to be removed. Due to resin contamination, none of the parts could be re-used. The operation required many teams of offshore personnel, including dive spread and the supporting vessels, as well as associated sub-contractors working around the clock. The cost of the removal operations resulted in millions in costs.

Case Study #2

A damaged power cable needed to be removed to allow for a new cable installation, with the existing power cable being secured by a Resin Type Hang-Off. Using a range of power tools, the offshore teams worked on one Resin Type Hang-Off Removal for several days, working 8 hour shifts to complete the job.

Resin Type Hang-Off Removal Solution/Alternatives

The Subsea Cable Hang-Off Systems supplied by Kintech Energy are free from harmful resin and the removal process is the reverse of the installation process, ultimately removing any reliance on using marine grade resins to maintain an airtight seal. Holding a demonstrable track record, the Kintech Resin Free Hang-Off has been installed in Offshore Windfarms around the UK and Europe on 33kV and 66kV subsea power cables.

Hassle free power cable removal with no Resin Type Hang-Off Removal, allows for cable repair or parts of the hang-off to be re-used or recycled, which eliminates disposal issues when dealing with contaminated parts by the cured resin.

The Kintech Resin Free Hang-Off (RFHO) protects the health and well-being of the cable installation teams, reduces the inevitability of substantial costs and time consumption, and can be easily recycled (or re-used).

Kintech Energy

The Market Leader of Resin Free Subsea Cable Hang-Off Systems

Working on more than 15 Offshore Windfarm projects around the UK, Europe, the Far East and USA, Kintech Energy Limited was created in 2013 to provide technical support for the design, manufacture, testing and installation of subsea power cables and Umbilicals.

Kintech Energy are also creators, developers and testers of the first and only Subsea Cable Hang-Off System, completely free from resin.

Kintech Energy provide a wide range of services and support for offshore energy projects, including Subsea Power Cables Design Verification, Project Management and Consultancy, Manufacturing Surveillance and Expediting, Onshore and Offshore Support, Engineering and Supply of the Resin Free Hang-Off and Engineering Analysis.

Cable TERMINATION, JOINTING, PULL-IN & Tooling UP TO 66KV

Thorne & Derrick supply LV MV HV Electrical Cable Joints, Terminations, Connectors, Tools & Power Distribution Equipment up to 66kV to the UK and international Offshore & Onshore Wind & Renewable industry – we hold several Framework Supply Agreements with international energy providers, wind turbine manufacturers and High Voltage Power Energy Companies. Thorne & Derrick specify and supply from extensive stocks market-leading brands in Cold Shrink, heat-shrink, silicone and EPDM rubber technology to support the energisation of High Voltage Power Cable Systems, 11kV, 24kV, 33kV, 66kV.

Based in the UK, we are highly customer responsive and absolutely committed to providing a world-class service. Since 1985, we have provided expert technical support and express delivery from extensive UK stocks to world-wide destinations.