US02 Utility Cable Tool for Semi-Con Shaving MV HV Cables by Ripley

Published 17 Sep 2019

US02 Utility Cable Tool for Semi-Con Shaving MV HV Cables by Ripley

US02 UTILITY Cable Tool

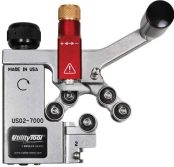

The new Ripley US02 adjustable cable semi-con shaving tool quickly and easily removes bonded semi-conductor layers from MV to HV power cables (5kV to 33kV) on end and mid span cable preparations.

The Ripley Tool’s compact and adjustable design accommodates a wide range of cable diameters (18 to 60mm) and semi-conductor thickness of up to 2.4mm.

The unique blade shape preserves the smooth surface on MV-HV cable insulation, eliminating the need for deburring or additional surface finishing – the optimal stability design of the cable jointing tool securely supports cables with diameters from 0.71″ to 2.36″ (18 mm to 60 mm) throughout the shaving operation.

The cable cutting blade depth is easily adjustable in increments of .1″ to achieve the perfect depth.

The US02’s unique blade shape provides a smooth surface finish with a bevelled semi-con edge and eliminates the need for any additional features.

Engineered to improve workplace safety and cable preparation the US02 tool replaces the use of traditional cable jointers knives. The cable tool is ergonomic in design and increases efficiency by providing greater leverage and reducing hand strain.

Multiple contact bearings securely cradle the cable and provide stability throughout the shaving operation to ensure accuracy for preparing cables prior to jointing and termination.

Four speed positions optimise performance and a stop position easily squares of the edge without the need for an additional clamp. If necessary the factory set blade can be quickly and easily replaced.

The Utility Tool US02 is the fastest, safest and most accurate tool for removing bonded semi-con from MV HV power cables.

Ripley US02 Utility Cable Tool

US02 Utlity Cable Tool

Features & Benefits

- Compact design accurately removes semi-con within 1.18″ (30 mm) of the jacket on mid-span and end stripping applications

- Precision blade depth adjusts in increments of 0.004″ (0.1 mm)

- Adjusts for 0.71″ to 2.36″ (18 mm to 60 mm) cable diameters with semi-con thicknesses up to 0.095″ (2.4 mm)

- A revolving ergonomic handle & accessible adjustment knobs reduce effort & potential strain from repetitive shaving functions

- Stop position squares off the edge to complete the shaving operation without the need for an additional clamp

- Factory-set blade is easily replaced

| Cable Compatibility | Primary Distribution Underground |

| Cable Access | Mid-Span, End |

| Min. Cable Outer Diameter | 0.71″ (18 mm) |

| Max. Cable Outer Diameter | 2.36″ (60 mm) |

| Min. Voltage | 5 kV |

| Max. Voltage | 35 kV |

| Insulation Thickness | Up to 0.095″ (2.4 mm) |

| Material | Aluminum |

| Length | 6″ (152.4 mm) |

| Weight | 1 lb 8.6 oz (698.5 g) |

| Replacement Blade Part # | US02-7501 |

Compatibility

| Tool Part Number | Cable Voltage | Cable Size ø | Semi-con Thickness | Chamfer Angle | Replacement Blade Part |

| US02 | 5kV to 35kV | 0.71″ to 2.4″ (18 to 60 mm) | Up to 0.095″ (2.4mm) | 12″ | US02-7501 |

|

|

|

|

| Unique blade shape leaves surface of insulation extremely smooth | Extra rollers provide tool stability on a range of cable sizes | Winding pin keeps semi-con strip from getting in the way | Equipped with four speed positions to optimise performance |

RIPLEY US02 OPERATING INSTRUCTIONS

- The cable jointer should retract the cutting blade to its highest position by turning the blade adjusting knob counterclockwise

- Open the cable tool and locate the cable end at the taper transition on the blade. Secure the cable in the tool (Fig. 2a, 2b)

- Turn the blade adjusting knob clockwise until the blade touches the semi-con screen of the MV HV cable

- Set the feed lever into a stripping position. #1 is a conservative feed

- Rotate the tool on the cable. As the tool advances on the cable, observe the semi-con chip and re-adjust the blade depth for a minimal thickness of insulation removal and an optimal shaving result

- The feed lever can be re-positioned diagonally toward the #2 for a more aggressive feed or fully at the #2 for the fastest feed. The feed can be backed down by moving the lever diagonally toward the Stop position

- Observe the shaved semi-con strip during operation. During the shaving process, do not allow the strip to get caught under the cable rollers. This will disturb the shaving result. A convenient technique is to wind the shaved semi-con strip around the tool bar handle while shaving (Fig.3)

- Another option is to guide the strip around the shaved insulation using the winding pin. (Fig.4)

- After shaving to the desired length, move the feed lever to the stop position. Make one full turn to finish the shaving. Remove the tool from the cable

Ripley US02-7000 Operating Instructions

Thorne & Derrick

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV