Cable Strikes | Surface Cable Damage by Mower

Published 18 May 2021

Cable Strikes

Utility Strike Avoidance Group

USAG have published a range of documents to assist industry understanding of the root cause and contributory factors behind specific incidents. The aim is to improve industry standards and reduce the number of cable strikes.

Cable damage is often caused by excavating machines – hand held tools such as pneumatic drills, crowbars, pins, picks and forks also expose workers to potential sources of danger when digging around underground cables.

The next in the series is a safety alert thanks to Highway England regarding surface damage to power cables during routine grass verge maintenance.

Surface cable Damage

Incident Overview

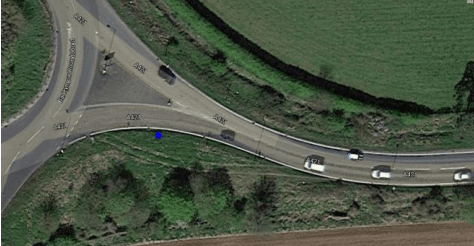

Electrical cable snagged by reform mower during grass cutting operation, 16 April 2020 at the Barley Mow junction A43/A421.

─ Electrical asset knockdown in same location on 28 June 2017 – made safe at that time (isolating and marking the location with a traffic cone)

─ Multiple grass cutting visits between June 2017 and April 2020 – no reported issues

─ A walkover on this occasion was undertaken and this is the same for all cuts – the cable was not observed, but sign frames were discovered and removed from site

Surface Cable Damage by Mower

| Cause Areas | Findings |

| Immediate Cause | Operators did not see any obstruction Cable was within the cut height of the mower |

| Underlying Causes | The cone used to mark the cable had been removed / damaged The passage of time between the knockdown and the incident may have permitted the cable to deviate from initial position, to be at a higher elevation |

| Root Causes | A cable was left on the surface where it could be compromised by grass cutting operations Standard operating practices at the time permitted an insecure method of highlighting the cable, albeit they did include the practice of electrically isolating the cable from the supply The grass cutting team were not advised of the potential of a cable No immediate permanent repair scheduled on the back of the temporary ‘make safe’ visit |

Cable Hangers | Cable Ducting | Cable Protection | Electrical Safety Equipment

The attending electrical crew isolated the cable at source, but left it ready for an imminent reinstatement – i.e. at the surface, marked with a traffic cone. This act prevented any later disturbance of the cable from causing any harm.

Grass cutting teams visually check the area, they located discarded sign frames, but missed the cable in the grass.

Working practice of the electrical teams has been enhanced by using more robust temporary bollards to highlight the hazard better. The bollard as shown may be placed provided with the directional arrow when replacing a permanent bollard, or plain yellow for a lighting column.

Protecting Cables Against Strikes & Restoring Power Post-Strike

Thorne & Derrick have been distributors for 3M Electrical since 1985 and can provide a range of reliable and easy to install Cable Repair Products – this includes Scotch Tapes, Scotchcast Joints and Cold Shrink Tubes to provide effective re-instatement of cable sheath jackets on all types of LV MV HV cables in onshore and offshore locations with safe or hazardous area workplace classifications.

Cable Repair Products

Our range of cable protection covers manufactured by Centriforce provide underground utility protection of LV MV HV cables including Tapetile (11kV) and Stokbord (33kV 66kV 132kV) – contact us to discuss Cable Damage Prevention Products including Dectamesh, the underground detectable warning tape for alerting excavators of the presence of buried cables and to prevent potentially lethal accidents during excavation.