PPE The Material Difference | Inherent v Treated Fabrics for Arc Flash Clothing & Protection

Published 26 Jul 2021

Choosing the Right PPE for You

Arc Flash Clothing, PPE & Flash Protection Kits

In a world awash with baffling technical speak, we cut through the jargon to explain the difference between treated and inherent flame resistance and the considerations when weighing up which to buy when evaluating competing garments to protect against arc flash dangers.

The Big PPE Fabric Debate

If you’ve been browsing PPE catalogues searching for arc flash and flame-resistant (FR) workwear, you have probably noticed there are many ways to describe the nature of the fabrics the garments are made from.

The two main phrases used in descriptions of arc flash clothing are inherent fabrics and treated fabrics. So, what’s the difference? And why does it matter?

VXS Inherent Fabric | Arc Flash Clothing Fabric

PPE | Treated Flame-Resistant Fabrics

A fabric described as treated will be made from fibres which aren’t flame retardant by their nature, but have either had a chemical applied, or have been through a chemical process, to make them fire resistant by creating a chemical reaction when set alight which then extinguishes the flame.

PPE | Inherent Flame-Resistant Fabrics

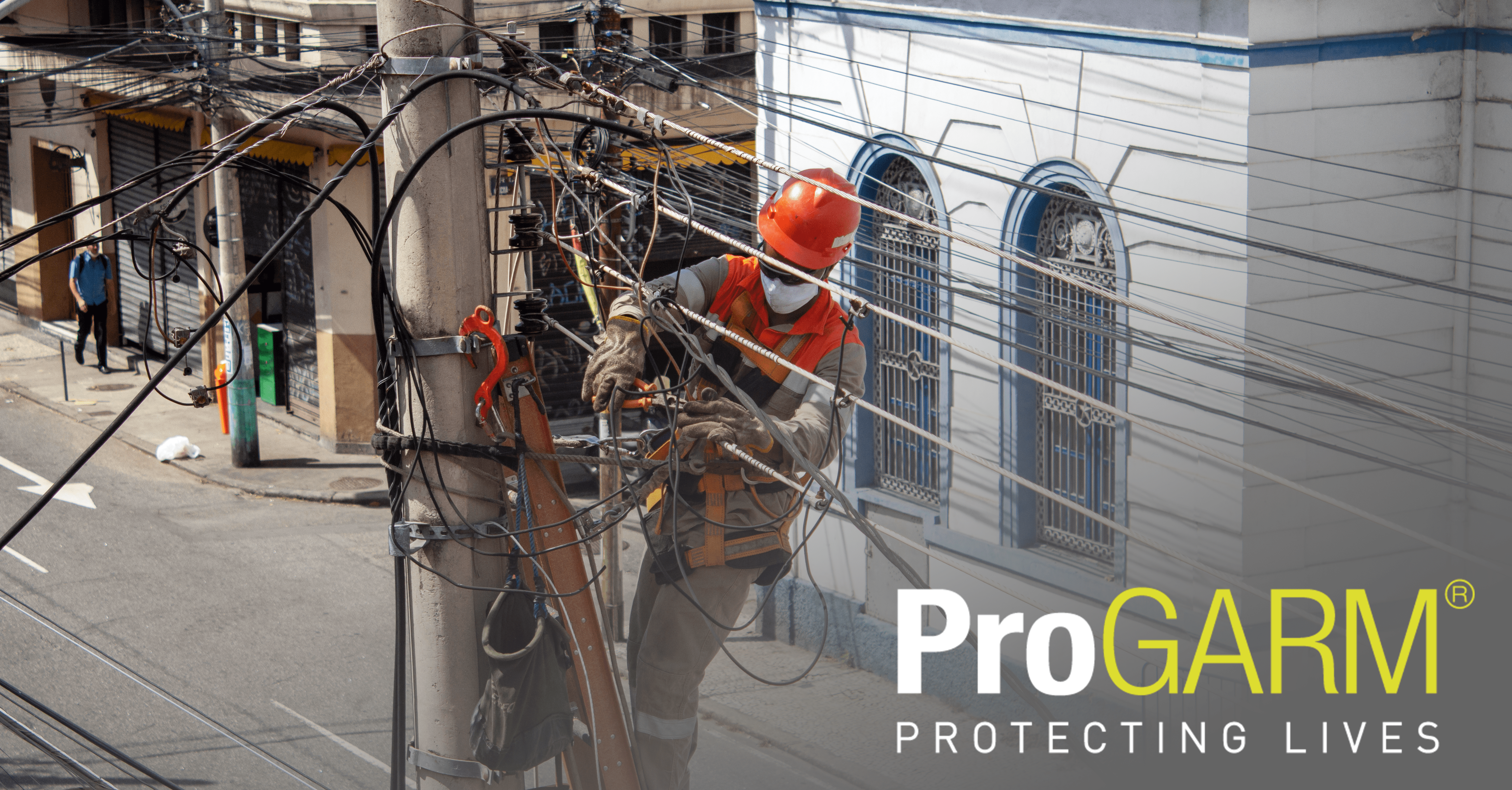

Protecting Utility Workers Carrying Out Maintenance, Repair & Operations on Overhead Lines & Underground Cables

If a fabric is inherently flame-resistant (also known as inherently fire-retardant), its ability to protect you from heat and flames comes from the polymer fibres of the fabric which, at normal oxygen levels, don’t ignite.

Pros & Cons of Inherent & Flame-Resistant Fabrics

Most of our ProGARM range of PPE is made using inherent fabrics because this makes it impossible for the flame resistance to degrade over time or be washed out altogether. These garments also don’t shrink when exposed to heat, helping to maintain critical air layers between the fabrics.

The advantage of treated fabrics is that they’re cheaper. However, this passes considerable responsibility to the employer to devise a system for wearers to monitor their garment’s wear and record its laundry cycles so the company knows when to replace the item due to degradation of the protective treatment.

VXS+ 100% INHERENT

ARC FLASH PROTECTION FABRICS

By manufacturing all ProGARM garments with our unique VXS+ inherent fabrics, we ensure they deliver durability, consistent protection and outstanding comfort.

In the past, many Flame Resistant Garments have suffered from reduced protection over time. Through normal washing, treated fibres gradually lose their Flame Resistant properties. With that decreasing level of protection your team members will be at greater risk of injury.

Treating fabrics can also leave them stiff and uncomfortable. Worryingly we hear of operatives deciding to wash treated garments multiple times to make them more comfortable before wearing them. Alternatively, they choose to keep wearing their older garments which have become more comfortable over time. Both of these practices leave your team exposed to a greater risk of injury.

Arc Flash PROTECTION. DURABILITY. COMFORT.

Electrical Safety & Arc Flash PPE

ProGARM ensures this isn’t the case with our unique 100% inherent VXS+ fabrics that offer superb protection for your team, as well as being durable and comfortable to wear.

VXS+ fabrics are manufactured with a combination of yarns which makes the garment inherently Flame Resistant. Compare VXS+ Fabrics with alternative fabrics and the differences are clear. As well as being 100% inherent, VXS+ fabrics make some of the most comfortable Arc Flash protective garments on the market. Through combining yarns in the manufacturing process, we can deliver fabrics that are flexible and comfortable, and from that create garments that are “as comfortable as pyjamas”.

As well as the ultimate protection, you also need garments that are durable. ProGARM garments are have been shown to last up to 70% longer than comparable garments used by our customers. Some non-ProGARM garments can also suffer from shrinkage and their colour fastness isn’t as resilient as it should be, resulting in faded high visibility workwear. VXS+ fabrics have been tested through more than 50 industrial washes to ensure the longevity of the garments. (The European standard only requires demonstrating colour fastness through 5 wash cycles.)

When you equip your team with ProGARM Arc Flash and Flame Resistant garments made from VXS+ Fabrics, you can be assured of durable protection and comfort that delivers protection throughout the life of the garment. That’s why every ProGARM garment is manufactured using VXS+ 100% inherent fabrics to offer the ultimate protection.

ProGARM is Pro-Choice

In developing our products, we’ve researched what’s important to our customers and fully appreciate that the decision between buying inherent or treated arc flash PPE isn’t an easy one when working with budget constraints and trying to keep their workforce safe.

That’s why we’ve been researching and developing treated garments. This gives you a choice without quite such a dilemma about the degree of safety compromise when making price-based decisions.

Our new coverall (available in four colour options) has been designed in a way that offers the cost saving advantages of being made from treated fabric, while also being robust enough to withstand up to 100 washes – lasting much longer than many competitor products, which are only tested up to 50 washes.

Electrical Safety STANDARDS

When it comes down to it, it doesn’t matter whether the fire protection in the fabric is inherent or added afterwards with chemicals. What you should make your decision based on is proof of standards.

We’re proud that all of our PPE clothing (not just our fabrics) meet EU Conformité Européenne (CE) standards and the new United Kingdom Conformity Assessed (UKCA) mark.

Our arc flash garments also hold EN certifications relevant to their intended purpose and/or industry. For example, all our garments conform to a minimum EN ISO 6330: 2012 DOMESTIC for washing, and some go further to meet the industrial washing standard (EN ISO15797: 2004 Industrial).

We go a step further too. Having achieved ISO9001 (Quality Management) and added Article 11B[KC3], all our supply chain partners meet the same standards. For us, there are no compromises on quality.

As well as electrical safety considerations, when developing our garments and fabrics, we always research what’s important to our customers. This helps us maintain our reputation for the best safety, quality and comfort standards.

Our independent testing looks at fading and shrinkage, as well as comfort of electrical PPE. And all our buttons, zips and press studs are made from the same military-grade plastics as NASA uses, so that they won’t melt and will still work if exposed to heat, flames or a high-voltage electric charge.

These decisions result in pioneering safety standards and mean that, when a casualty needs urgent medical attention following an incident, you will be able to unfasten and remove the clothing far more easily.

You’ll find a label on each of our electrical safety workwear products, outlining which European and UKCA certifications it meets[KC5] [LT6], along with garment care guidelines.

If you would like a chat with one of our arc flash experts to discuss your PPE requirements, give us a call on +44 (0)191 410 4292.

Further Reading

- Arc Flash | Don’t Let the Summer Sun Compromise Your Electrical PPE

- Arc Flash Risks In The Rail Industry

- Arc Flash Survivor Story – Jason Brozen

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.