Cable Strikes | Ingrebourne Valley – 415V Cable Strike

Published 18 May 2021

Cable Strikes

Utility Strike Avoidance Group

USAG have published a range of documents to assist industry understanding of the root cause and contributory factors behind specific incidents. The aim is to improve industry standards and reduce the number of cable strikes.

Cable damage is often caused by excavating machines – hand held tools such as pneumatic drills, crowbars, pins, picks and forks also expose workers to potential sources of danger when digging around underground cables.

Cable Hangers | Cable Ducting | Cable Protection | Electrical Safety Equipment

Incident Overview

What Happened?

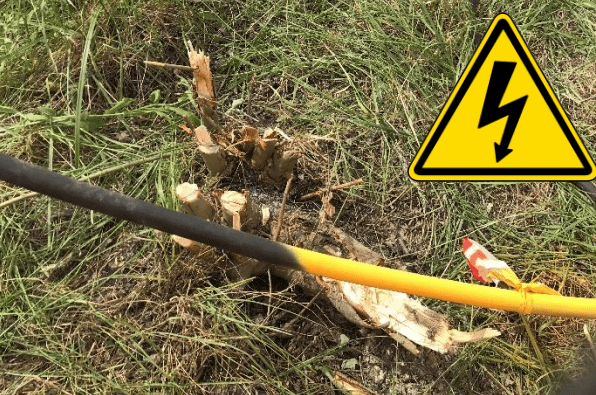

On the 2nd July, at approximately 15:35, a service strike occurred when an excavator tracked over an above ground 415V armoured cable. This cable was located in the vegetation clearance area of the satellite compound in Ingrebourne Valley. The excavator (with a grab attachment) was completing vegetation clearance works for site compound set up.

The service strike caused immediate loss of power to the neighbouring site welfare cabins of Brown and Mason. Following the strike the excavator operator stayed in the cab and called for assistance. Brown and Mason representative and their electrician were called to the scene and confirmed power had been lost and the area made safe. The excavator driver was then able to track back to safety and stand down.

The power was supplied by a generator situated in the work area of Package B. Perfect Circle and Socotec Site Management believed the area was free from services. They had received a guidance certification from the site owners which was misunderstood and heavily relied on. The certificate also failed to mention the power generator.

Immediate Causes

Failure to follow PAS 128 correctly, before any works commenced. They did not look at their surroundings and investigate any furniture which could have utility supplies, in this case the generator and cabins.

Had this been undertaken the direction of the over ground cable could have been identified, prompting further careful investigation prior to the works being undertaken.

Ingrebourne Valley 415V Cable Strike

Prior to vegetation clearance work in the vicinity of the generator, no communication took place with site neighbours Brown and Mason to address cable management/direction.

CAT and Genny scanning from the live generator cables did not take place, which would aid the clarification of the cable’s direction.

Lessons Learnt

Too much reliance was placed on service plans and client certification of services. These documents must be treated as guidance only. All services must be identified and traced on all packages.

Appropriate site planning would have identified the generator and cables as a hazard for the works. Works should not have commenced in the area of the generator until cable direction and status (live / terminated) was clarified.

There was a failure to adapt and change methodology for site restrictions caused by the dense vegetation. Where site restrictions affect prescribed and agreed methodology of works, works must stop, be reassessed, re-briefed and signed by those completing the tasks.

Perfect Circle Site Management failed to enforce PAS128 / CAT & Genny usage on site by subcontractors. All services need to be traced out, if vegetation prevents the use of CAT & Genny, stop works and reassess the methodology of works. Reduce vegetation following a safe system of work to aid access and identify services.

PAS 128

PAS defines a hierarchy of detection methods to be used to detect underground utilities:

- Survey type D shall use desktop search techniques to identify existing utility data within the survey area.

- Survey type C shall comprise a site reconnaissance to identify physical features that support the existence of utilities within the survey area.

- Survey type B shall use geophysical techniques to detect and identify utilities within the survey area.

- Survey type A shall comprise exposing the target utility(ies) within the survey area to confirm and record the location and other attribute data following safe digging practises.

Protecting Cables Against Strikes & Restoring Power Post-Strike

Thorne & Derrick have been distributors for 3M Electrical since 1985 and can provide a range of reliable and easy to install Cable Repair Products – this includes Scotch Tapes, Scotchcast Joints and Cold Shrink Tubes to provide effective re-instatement of cable sheath jackets on all types of LV MV HV cables in onshore and offshore locations with safe or hazardous area workplace classifications.

Cable Repair Products

Our range of cable protection covers manufactured by Centriforce provide underground utility protection of LV MV HV cables including Tapetile (11kV) and Stokbord (33kV 66kV 132kV) – contact us to discuss Cable Damage Prevention Products including Dectamesh, the underground detectable warning tape for alerting excavators of the presence of buried cables and to prevent potentially lethal accidents during excavation.