MULETAPE CALCULATOR | How To Select The Right Cable Pulling Tape For The Job

Published 28 Oct 2020

MULETAPE Calculator | selecting the right tape for the pulling of cables

Muletape

NEPTCO is a global leader in the manufacturing of materials used for the Detection & Pulling of Cables, including MULETAPE, for a wide variety of commercial and industrial applications. This Blog demonstrates how the correct tape for pulling cables can be selected, with the MULETAPE calculator.

MULETAPE is a unique pull tape designed to reduce damage to the underground plant – resulting in improved efficiency, and enhanced worker safety.

To see the benefits of using MULETAPE over traditional cable pulling methods, see our Blog: MULETAPE V ROPE

NEPTCO tapes, distributed by Thorne & Derrick, are manufactured with a low stretch polyester material that distributes heat across its wide, flat profile. This improves efficiency and prevents “snap back”, which occurs when a rope under high tension elongates and either breaks or snaps back; often injuring the installer.

A variety of reel lengths of the cable pulling tape is available to suit any installation. Available in a variety of strengths (up to 6,000 lbs or 2727 kg) which enables extensive application use.

MULETAPE pulling tape for wires and cables is a laboratory and field tested for strength, temperature and chemical resistance, low elongation, low coefficient of friction (slips easily even on long pulls), and long life.

MULETAPE CALCULATOR

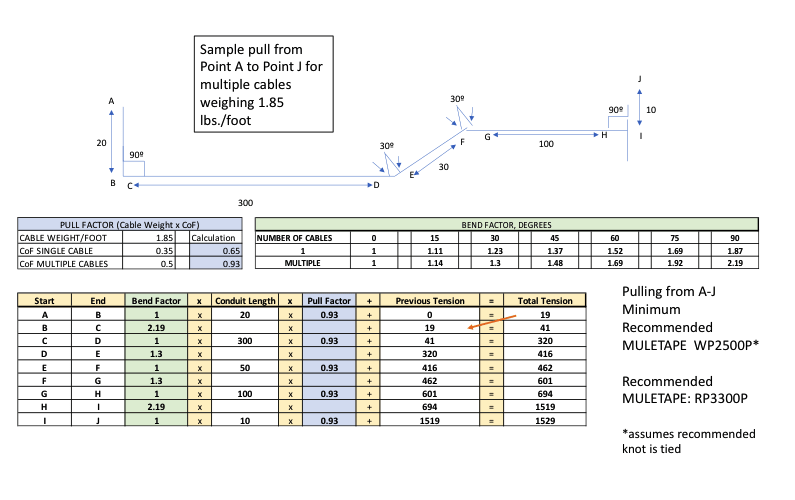

Cable weight is the biggest influence in MULETAPE recommendations, followed by the number of bends and finally the conduit size.

Pulling tension is a cumulative calculation with each bend in the conduit run contributing to more drag as the pull goes on. It is important to consult the cable manufacturer’s specifications for the maximum pulling tension before installing the cable. If pulling tensions are more than the maximum recommended limit, an intermediate pull box or manhole will need to be placed. MULETAPE is offered in tensile strengths varying from 400 to 6000 lbs.

Pulling forces vary depending on fill ratio, terrain and underground architecture; actual field conditions should be considered. The tension calculator below is intended to be used as a guide.

POINT TO POINT LOOK UP TABLE – FOR BEND ANGLE, DEGREES

| Bend Angle, Degrees | |||||||

| 0 | 15 | 30 | 45 | 60 | 76 | 90 | |

| Single Cable | 1 | 1.11 | 1.23 | 1.37 | 1.52 | 1.69 | 1.87 |

| Multiple Cable | 1 | 1.14 | 1.3 | 1.48 | 1.69 | 1.92 | 2.19 |

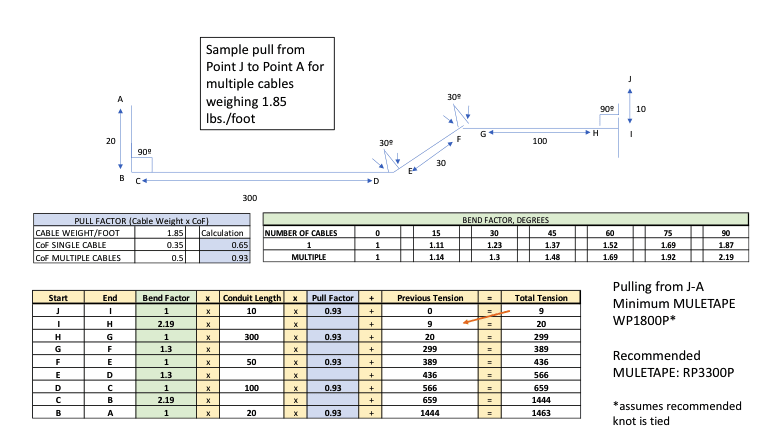

It should be noted that pulling tension can vary on the same pull. It is important to determine the starting point that will exert less strain on the cable. Usually, lower tension can be achieved by placing the cable reel closer to the shortest 90-degree bend. It might be helpful to make a sketch of the conduit run, showing bends.

The following is an example of a 460-foot pull of a 3 single conductor #2 15kV in 4” PVC conduit. The cable weighs 1.85 lbs. per foot. Please note the tension changes depending on the starting point of the pull.

As you can see from the examples above, pulling from point J to A results in a lower overall pulling tension; consequently, assuming the recommended knot is tied, a lighter duty MULETAPE can be used to complete the job.

Muletape Calculator Instructions

To apply these formulas in your cable pulling application, follow these steps:

- Determine the weight per foot of your cable.

- Multiply the weight by the coefficient of friction for either single cable or multiple cables to determine the pull factor.

- Sketch the pull and determine the lengths between bends.

- Multiply the bend factor by the length of conduit.

- Multiply the result by the pull factor.

- Add the resulting tension to the next length of conduit and repeat steps 2-5.

- Repeat step 6 until the last point results in the cable exit.

- Determine if the tension is lower if the cable is pulled from the opposite end by repeating the same steps from the other end.

MULEKNOT + MULETAPE = a winning combination!

The weakest point of MULETAPE is the knot, and a poor knot can severely impact the tensile performance of the pulling tape. We recommend a MULEKNOT™ or blood knot, which can provide 80% of the rated tensile strength of MULETAPE.

The MULEKNOT is designed to maximize the pulling strength of NEPTCO MULETAPE, while providing a simple, reliable method of splicing lengths of tape in the field. Using the MULEKNOT instead of a traditional bowline knot can greatly increase the pulling strength of the splice and/or connection.

For more information on the MULEKNOT, please see the attached data sheet.

Further Reading

- MULETAPE v Rope : Pulling Cables Into Cable Ducts To Avoid Duct Cutting

- Lace Up Cable Socks – A Guide For Users When Pulling Cables

- Cable Pulling | Safe Pulling of Cables Using Manual Laying

CABLE PULLING EQUIPMENT

Thorne & Derrick International are the UK’s leading stockist and supplier of Cable Pulling & Cable Laying Equipment for the installation of underground cables and overhead lines up to 400kV – the products support cable pulling teams to install LV MV HV cables into trench, cable duct, risers and all forms of cable containment.

Further Reading

-

NEPTCO MULEKNOT

Size: 169.48 KB

NEPTCO MULEKNOT

Size: 169.48 KB