11kV 24kV Elbow Connectors – Interface A Switchgear Transformers – Prysmian Elascon

11kV 24kV Elbow Connectors – Interface A Switchgear Transformers – Prysmian Elascon

Prysmian Separable Interface A Elbow Connectors are suitable for the connection of polymeric MV cables to transformers and switchgear units in outdoor or indoor installations with a continuous current rating of 250A.

Suitable for single polymeric insulation (PE, XPLE, EPR) with aluminium or copper conductors with sizes between 25 to 95mm² – insulation voltage up to 24kV and operated when de-energized.

The separable elbow connector meets CENELEC HD 629.1 S2 IEC 60502-4 — NF C 33-051 — NF C 33-001, Interface A meets CENELEC EN 50180 and EN 50181 and the metal conductor contact is compliant with IEC 61238-1 class A and HN 68-S-91.

Elbow Connector MV HV Interface A 11kV 24kV

Elbow connector MV HV Interface A – Features & Benefits

- For class tension 24kV, only one product reference allows to cover the section from 25mm² to 95mm², copper or aluminium

- No need for special tools – no heating, taping or filling

- Vertical, angled or inverted position

- No minimum distance between phases

- Individual clamping by stainless steel brace

- The three phases may also be locked together and to the equivalent by use of metallic rings (supplied on request, separately or already fitted into the moulded groove)

- Energising may take place immediately after the connector is plugged into its bushings and dead end plug

- Unplugged connector must not be energised

- Supplied as a kit of 3 single connectors containing all the necessary components

- Shipping weight and volume (approx) of kit: 3kg /0.006m³

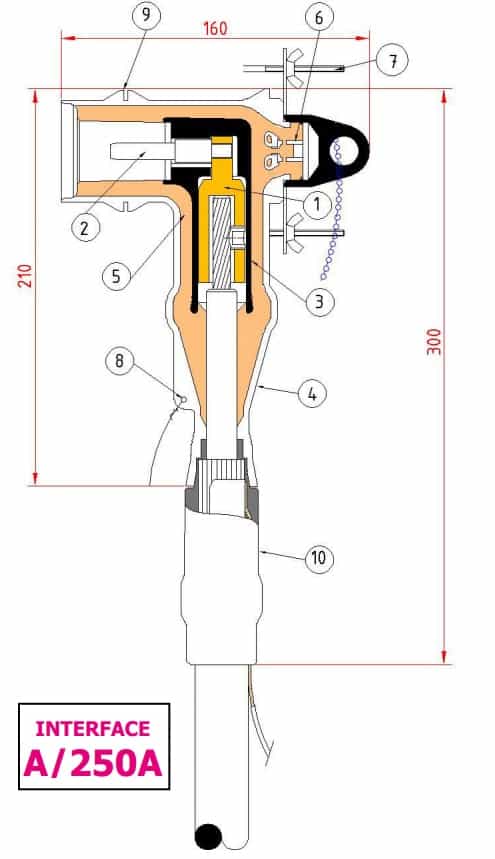

Separable Elbow Connector (Interface A 250A) – Diagram

1. Mechanical contact piece Al/Cu 25/95mm²

Only one conductor contact covers the section from 25mm² to 95mm², copper or aluminium core. No need for special tools.

2. Copper contact pin

Copper pin, screwed into the mechanical conductor contact.

3. Semi-conducting inner screen

Insert of semi-conducting EPDM enclosing the mechanical conductor contact connections so that ionization of the air remaining trapped inside is prevented.

4. Semi-conducting outer envelope (thickness 3mm)

Jacket made of semi-conducting EPDM. Its design provides relief of electrical stress as does a cable screen. Its connection to the cable screen ensures that the assembly is maintained at earth potential. It allows to evacuate the short-circuit currents

5. Insulating body

Moulded from insulating EPDM, for integral reconstitution of insulation. It maintains a uniform contact pressure on the cable insulation and on the bushing interface, providing an excellent moisture seal.

6. Test point

Electrically protected by a cap made of semi-conducting EPDM. A capacitive voltage divider allows the checking of absence of voltage before removing the connector.

7. Locking brace

Stainless steel brace fastening the connector onto its mating bushing of other accessories.

8. Earthing eye

For connection of the outer envelope to the metallic cable screen.

9. Groove locking ring

For the fitting of a metallic ring (supplied on request) when 3-phase locking is required.

10. Earth cover

Moulded semi-conducting EPDM. Ensures watertight protection of the earthing device.

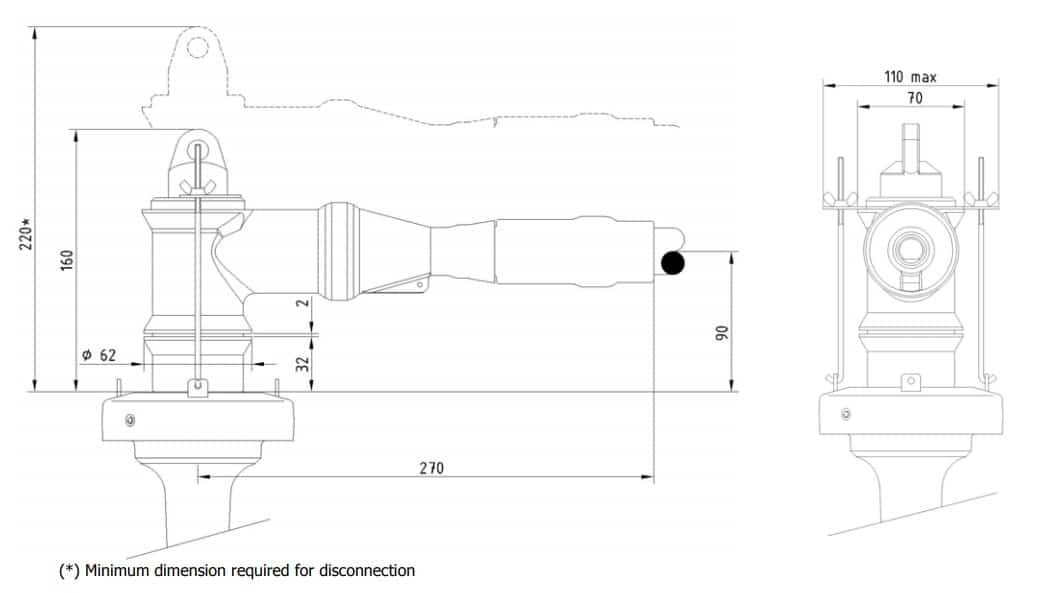

Separable Elbow Connector MV HV Interface A – Overall Dimensions Installed On Bushing

| Voltage | Dia Over Insulation mm | Conductor Size mm² | Prysmian Elascon Kit Reference | |

| Min | Max | |||

| 12kV | 11.8 | 17.2 | 25 / 50 | MSCE/EC-250-A-12-25/50* |

| 17.2 | 25 | 70 / 95 | MSCE/EC-250-A-12-70/95 | |

| 17kV | 13.7 | 17.2 | 25 / 35 | MSCE/EC-250-A-12-17-25/35* |

| 17.2 | 25 | 50 / 95 | MSCE/EC-250-A-12-17-50/95 | |

| 24kV | 17.2 | 25 | 25 / 95 | MSCE/EC-250-A-12-24-25/95 |

T&D distribute the full Prysmian Separable Connector range including Tee Connectors, Straight Connectors & Elbow Connectors

Read Our Blog: The Next Generation Of 11kV Transformers For Medium & High Voltage Networks