Surge Arresters | SSI Power Supply Surge Protection (Rail Trackside)

Surge Arresters | RTM Series

SSI Power Supply Surge Protection (Rail Trackside)

RTM surge protection devices safeguard equipment connected to AC power supplies from the harmful effects of lightning strikes and voltage surges. The RTM Series includes single-phase devices with either MOV or SAD technology, which help reduce the risk of failure for Trackside Functional Modules (TFMs) during lightning storms. This, in turn, enhances Solid State Interlock (SSI) performance and extends the lifespan of the protected equipment.

These surge arresters are typically installed on incoming power supplies or tail cables to protect the 110V, 140V, and 650V power supplies in SSI equipment cases and rooms. Offering a highly effective protection solution, these units are ideal for safeguarding signals, points, and level crossings at stations and along the tracks.

The RTM Series feature high surge current handling capabilities which operates in two stages to ensure continuity of transient suppression. Under normal conditions the RTM will automatically reset after clamping smaller, more commonly occurring surges, and two green lights indicate that full protection is present. However, should a surge current in excess of 75kA or 12kA (depending on the model selected), appear on the line, it will be clamped by the RTM, but the first protection stage may possibly suffer damage and fail safe.

In this case, one green light on the damaged RTM module will turn off. While the system will remain protected, the unit should be replaced before another large surge can affect the second stage. If the RTM module’s lights are not illuminated, no protection is in place, although unprotected power will still be supplied.

The protection of signals, points, level crossings, and other critical assets at each station, as well as in between stations, is essential. This protection also extends to expensive power assets.

The benefits of this protection include an extended service life for the protected equipment, a reduced failure rate of Track Fault Monitoring Systems (TFMs) during lightning storms, and overall improved system performance. Additionally, the cost of surge protection devices is far outweighed by the safety issues, downtime, and equipment replacement costs they help to mitigate.

Quality assurance for this protection system is guaranteed through approval to the BS EN ISO 9001 standard. Approvals: Network Rail Certificate of Acceptance PA05/00602 Issue 5.

RTM SERIES Installation & Maintenance

The RTM is connected in parallel (or “shunt”) across the supply to be protected. The connecting cable does not carry the supply current, only the current associated with suppressing the transient overvoltage.

The unit is provided with mounting for Top hat style symmetric DIN rail (35 x 7.5), and terminals accept cables up to 35sqmm. However the RTM must be connected with cable having a cross section of not less than 10mm² and must be connected to supply terminals using cable of the shortest length possible (it is recommended that, if possible the cable length should not exceed 25cm.)

Fusing

The RTM Series is suitable for direct connection to a line rated up to 100A with 16sqmm min connecting cables. However it should be remembered that if the unit were to see a surge in excess of its designed capability, then the main fuse would be ruptured and the supply disconnected. Provision of additional inline disconnecting fuses to the RTM will overcome the above and also provide isolation for maintenance and exchange.

Units can be connected to a supply of greater than 100A providing inline fuses rated 50A min – 100A max (BS HD60269-2:2010, BS88-2:2010) are fitted. In order to discriminate with the supply fuse, the inline fuse should be in the ratio of 1:2. The inline fuses can be replaced by MCBs providing they are type C.

Component Technology

The RTM series of surge protection devices provides protection of critical assets through carefully matched high energy absorbing elements.

SAD Surge Protection Modules

Silicon avalanche diode (SAD) models conduct maximum current without any increase in clamping voltage. They offer extremely low clamping of <500 volts and an exceptionally fast response time of less than <5 nanoseconds. The robust nature of this component technology offers long product life expectancy, ideally suited for mission critical applications.

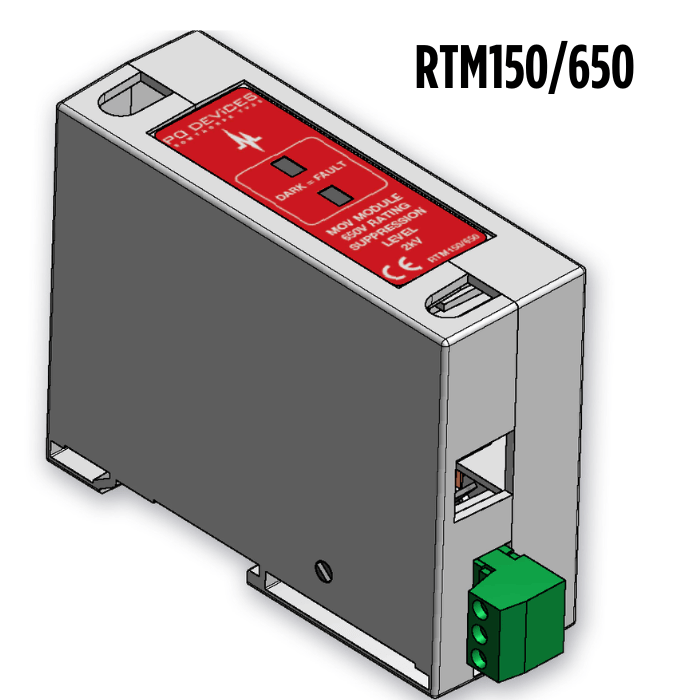

MOV Surge Protection Modules

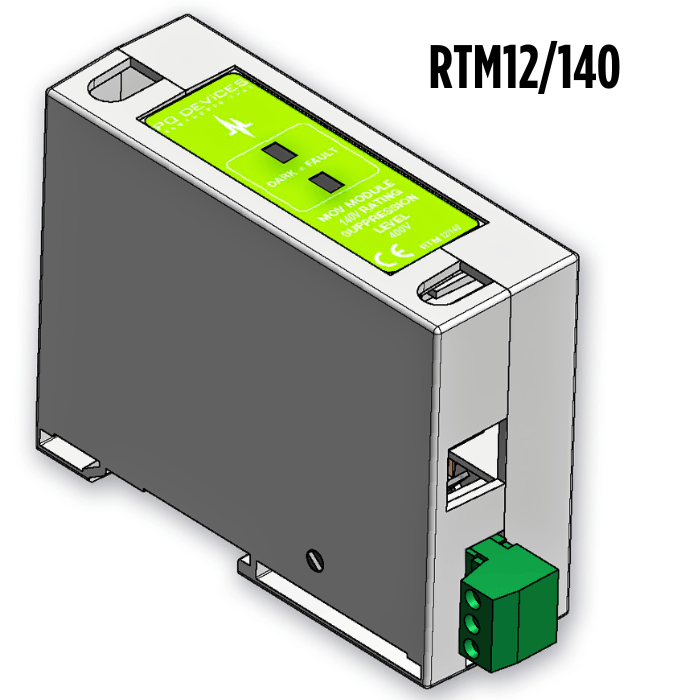

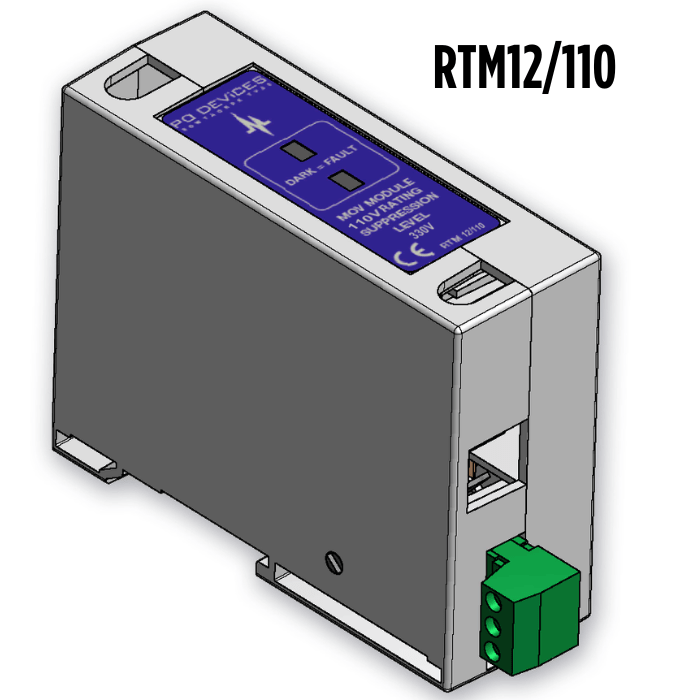

Metal oxide varistor (MOV) models provide excellent clamping of transients within <10 nanoseconds and are ideally suited for high/medium/low risk applications.

Surge Protection (Rail Trackside) – Benefits

- Maximum surge current ratings exceed the 10kA requirements of BS6651:1999 Annex C, to provide long life and low maintenance

- Meets the requirements of BS EN62305:2006 and BS EN61643-11/12 – Type II, Class II

- BS6651:1999 Annex C – Location category C

- Protection of equipment connected to AC power supplies against the damaging effects of lightning strikes or voltage surges

- Fitment to nominal 110V, 140V & 650V SSI AC power supplies in the line side equipment housings

- Two stage (redundant) protection with pre-failure indication

- DIN Rail mountable

- Dual thermal and current overload fusing

- Full protection status indication with remote signalling

- 650V model (RTM150/650) approved for use on AC electrified, DC electrified and non-electrified lines

- 110V and 140V models (RTM12/110 and RTM12/140) approved for use on AC electrified and non-electrified lines

- MOV and SAD component technology

- Compact design

- Low “let through” voltage.

- Resilient design with long service life

- Simple installation

|

|

|

|

| Part Code: Network Rail Code: |

RTM12/110 PADS No: 086/047167 |

RTM12/140 PADS No: 086/047166 |

RTM150/650 PADS No: 086/047165 |

| Description | 12kA Single Phase 110V SAD Module |

12kA Single Phase 140V SAD Module |

75kA Single Phase 650V MOV Module |

| Voltage Rating | 110V rms | 140V rms | 650V rms |

| Operating Voltage Range: | 121V rms Max. | 154V rms Max. | 650-800V rms |

| Maximum Current Rating | Unlimited (Parallel Connection) | ||

| Maximum Surge Current Handling (8/20 μ s): | 12kA | 12kA | 75kA |

| Response Time: | < 5 ns | < 5 ns | < 10 ns |

| Power Consumption: | Negligible | ||

| No system impairments auto reset after surge has occurred: |

YES | YES | YES |

| Terminals: | 35sqmm max. 2.5sqmm max – Remote Signalling | ||

| Operating Temperature: | -40ºc to +70ºc | ||

| Light Emitting Diodes: | 2 Green – Full Protection 1 Green – Reserve Protection No Green – No Protection, or No Power |

||

| Case Material: | Light Grey FR ABS | ||

| Type according to BS EN61643-11 | SPD Type II, Class II | ||

| Compliant With: | BS6651: 1999 Annex C Location Category C | ||

| Dimensions: | L :100mm x W :35mm x D :78mm | ||

| Weight | 160g | 160g | 160g |

| Let Through Voltage (6kA 8/20μs) | 260V | 370V | <1.9kV |

AN Wallis & PD Devices LTD

Overvoltage Protection for Power Generation Equipment

SPD | Surge Protection Devices | Earthing & Lightning Protection

AN Wallis has fully acquired PD Devices Ltd, making it a 100% subsidiary of the Wallis Group.

PD Devices Ltd specialises in the design and manufacture of Earthing, Lightning Protection & Surge Protection Systems.

The PD Devices range of Surge Protection Devices (SPD’s) protect against transient over-voltages and increase the reliability of Low & High Voltage electrical equipment systems utilising their Metal Oxide Varistor (MOV) technology: this includes standard Mains Power, Data, Photovoltaic Protection & Equipotential Bonding applications.

Specialist application Surge Protection Devices include: Solid State Interlocking (SSI) | Airfield Lighting Circuits | Rail Trackside

AN Wallis, based in the UK are a leading manufacturer of Earthing & Lightning Protection Products, using high conductivity copper to BS EN 13601 – their earthing products are installed to protect buildings, overhead lines and low/medium/high voltage substations (LV-MV-HV) against potentially catastrophic damage that can be caused by a lightning strike resulting in short circuiting.

The Wallis product range includes copper earth rods (solid copper, copper bond and stainless steel types), earth bars, copper tape, earth clamps and aluminium tapes.