Cable Strikes | 132kV Cable Strike at Sellafield

Published 18 May 2021

Cable Strikes

Utility Strike Avoidance Group

USAG have published a range of documents to assist industry understanding of the root cause and contributory factors behind specific incidents. The aim is to improve industry standards and reduce the number of cable strikes.

Cable damage is often caused by excavating machines – hand held tools such as pneumatic drills, crowbars, pins, picks and forks also expose workers to potential sources of danger when digging around underground cables.

Cable Hangers | Cable Ducting | Cable Protection | Electrical Safety Equipment

Incident Overview

CDM construction site at Fellside

Summary

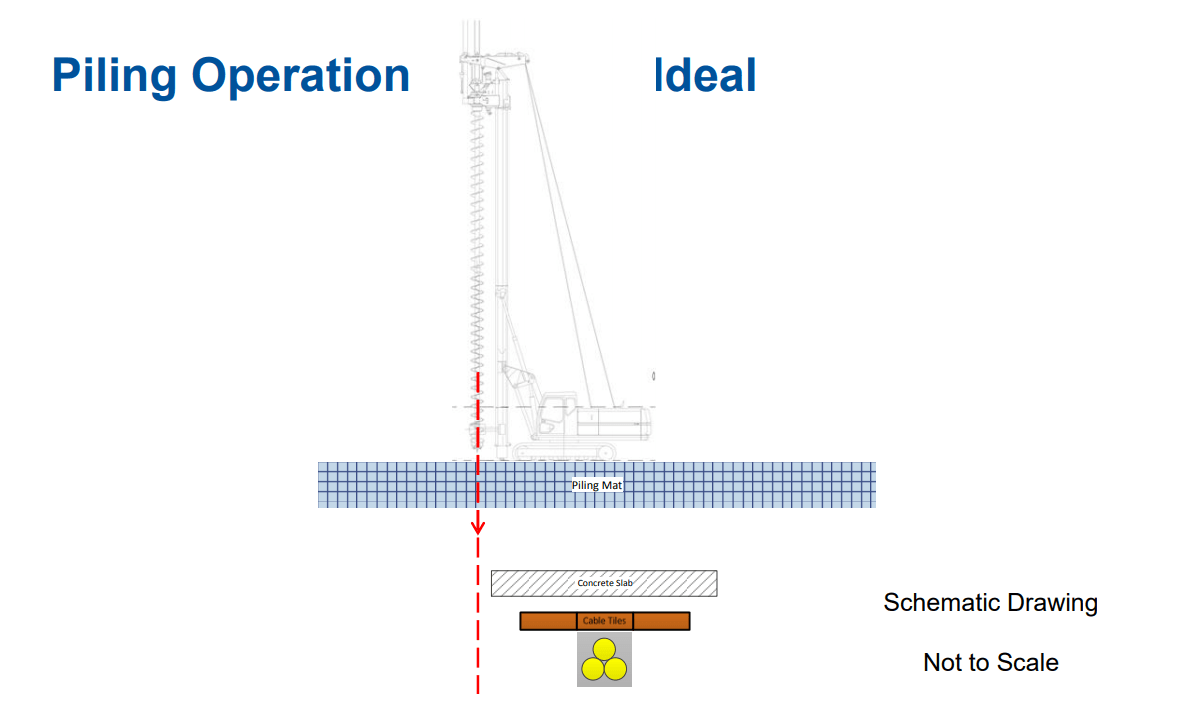

The incident happened at the Fellside CDM area; part of a project to build new fuel storage tanks for the New Steam Generation Plant, NSGP. The piling work was ongoing around a live underground 132kV cable, during which an auger struck the cable.

Pile 46 formed through 2 phases of cable

Consequences

- Banksman was put at risk of injury by electrocution

- CHP lost power supply to Gas Turbines 1 and 2 resulting in loss of significant steam raising capability and reducing the steam resilience to site

- Large voltage dip on Sellafield site leading to plant trips and disruption on the site

- The Project was delayed several weeks with additional costs

- Reputational damage to all parties

Direct Cause

Auger penetrated the 132kV cables (HTF1201)

– This cable provides power to the CHP GTs 1 and 2

– Also exports excess power generated by the CHP plant to the National Grid

Root Causes/Contributory Factors

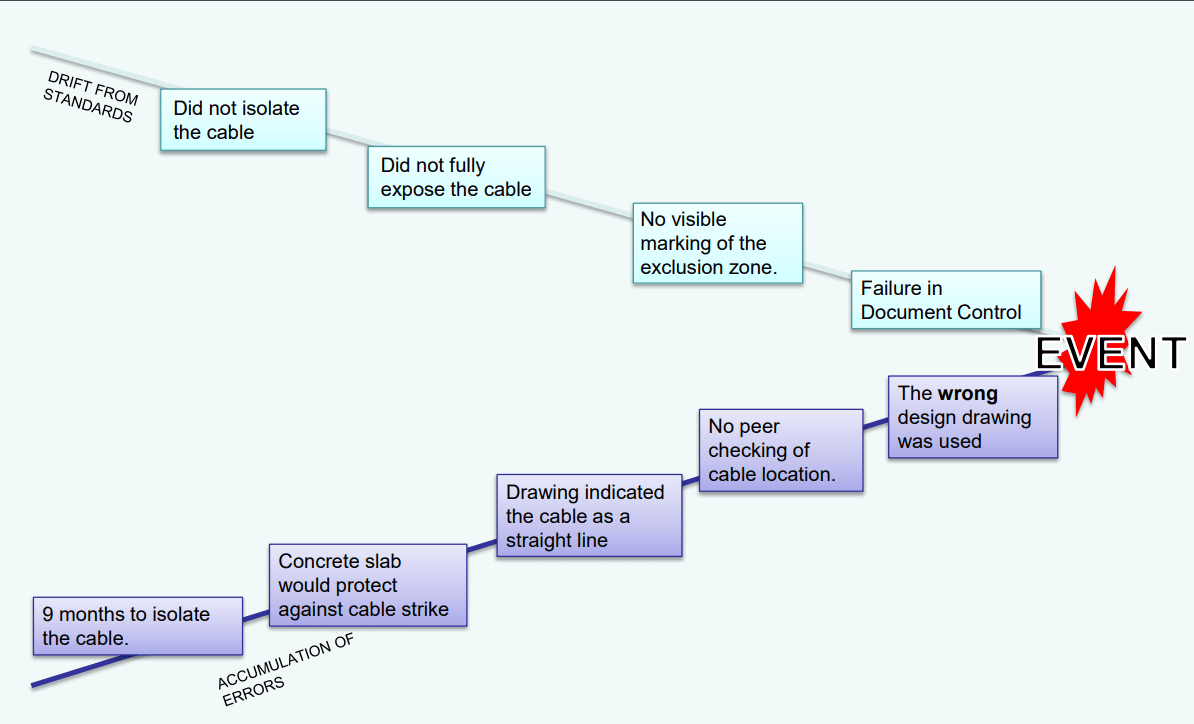

Failure to accurately identify the route of the cable and manage its location.

| Isolation would take 9 months | Confirmation Bias |

| Failure to isolate the cable | Risk Perception |

| Cable not fully exposed as a result of failure to isolate | Risk Perception |

| Cable was in a straight line | Confirmation Bias |

| Misconception of the purpose of the concrete slab | Risk Perception & Confirmation Bias |

View along centre line of excavated slab

Slab position markings in relation to cable

Root Causes/Contributory Factors

Failure to apply adequate document control procedures resulting in the use of a superseded design drawing.

| Document control system limited access to the drawings Not available to the Engineer on the ground |

Error Tap |

| Individuals failed to challenge the different versions of the drawings | Human Performance |

| Lack of escalation when challenged | Human Performance |

Use of Superseded Drawing (C06, not C07)

The centreline of the concrete slab was not laid over the centreline of the tiles or the cable. The pile was sunk as per version C06 of the drawing, rather than the current C07

Learning from this Event

- A lack of independent challenge to assumptions played an important part in influencing the course of events.

- It can be easy to lose sight of how our decisions can inadvertently influence safety.

- How could your work influence safety?

- What techniques and methods would help reduce this influence on safety?

Key Recommendations

The SL process for Excavations amended to a mandatory standard, that services must be isolated and positively identified (i.e. exposed) prior to excavations. If unachievable, then a formal justified mitigation to approved by a principal SAP and signed off by the Chief Engineer.

The ISA collaboration should implement improvements to their assurance and document control arrangements to ensure that the most recent and accurate information is are readily available to end users.

Arrangements equivalent to SL’s own mechanisms for providing independent challenge, oversight and learning should be developed within delivery partnerships. The Intelligent Client organisation to be educated in Human Performance, Human Factors, Nuclear Safety.

SL, PX and the ISA group should undertake collaborative working improvement activities in order to improve sharing of experiences and to foster healthy internal challenge.

Protecting Cables Against Strikes & Restoring Power Post-Strike

Thorne & Derrick have been distributors for 3M Electrical since 1985 and can provide a range of reliable and easy to install Cable Repair Products – this includes Scotch Tapes, Scotchcast Joints and Cold Shrink Tubes to provide effective re-instatement of cable sheath jackets on all types of LV MV HV cables in onshore and offshore locations with safe or hazardous area workplace classifications.

Cable Repair Products

Our range of cable protection covers manufactured by Centriforce provide underground utility protection of LV MV HV cables including Tapetile (11kV) and Stokbord (33kV 66kV 132kV) – contact us to discuss Cable Damage Prevention Products including Dectamesh, the underground detectable warning tape for alerting excavators of the presence of buried cables and to prevent potentially lethal accidents during excavation.