Cable Strikes | How To Support LV to 33kV Electricity Cables

Published 11 May 2021

Cable Strikes

Utility Strike Avoidance Group

USAG have published a range of documents to assist industry understanding of the root cause and contributory factors behind specific incidents. The aim is to improve industry standards and reduce the number of cable strikes.

Cable damage is often caused by excavating machines – hand held tools such as pneumatic drills, crowbars, pins, picks and forks also expose workers to potential sources of danger when digging around underground cables.

The next in the series is a safety alert thanks to Highway England regarding incidents caused by contractors incorrectly supporting power cables.

Incident Overviews

Below are some case studies and a useful guide on how to support exposed LV to 33kV cables spanning your excavation, supplied by SP Energy Networks.

The above image highlights a situation which could easily be avoided if the correct planning processes had been implemented at the pre-construction phase of the project.

The task for the contractor was to expose the utilities and excavate a further 3 metres past the electrical network, leaving the low voltage (PILC) cable supported with rope at two locations.

The inadequate level of support of the electrical network at this location is not acceptable to ScottishPower; the contractor was advised to backfill the exposed cable with caution.

Given the ongoing mechanical excavations, lack of cable support and that contact with the electricity network was a possibility the contractor was advised to contact SP Energy Networks Customer Connections department to progress a cable deviation to remove the hazard.

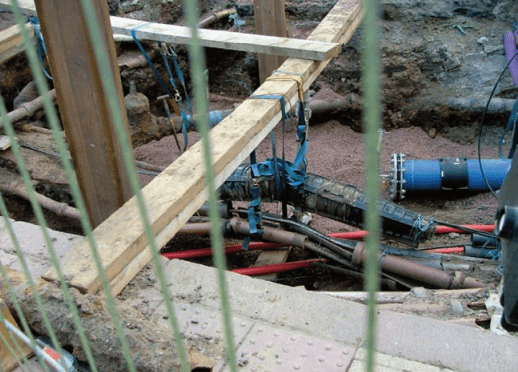

The above image demonstrates how NOT to support an electricity cable.

The contractor has gone some way to supporting the Low Voltage cable in the correct way by using sturdy batons and ratchet straps, however the weakest part of the electrical network are the LV cable joints.

ScottishPower would recommend that exposed cables with joints should not be supported in this situation at any time due to the probability of the weight of the joints pulling the cables out of the joint connections. To carry out support of electrical cables a method statement and a safe system of work will be required by ScottishPower prior to works being undertaken.

The contractor has gone some way to supporting the underground network cables by using ratchet straps, however in this situation the cables are all bunched together and have sagged. The weakest part of the electrical network in this situation are the cable joints with the added weight of the exposed cables.

ScottishPower would recommend that exposed cables with joints should not be supported in this manor due to the probability of the weight of the joints/sag on the cables pulling the cables out of the joint connections. Every excavation has different dimensions to consider prior to carrying out work to support the electrical cables.

A method statement and a safe system of work will be required by ScottishPower prior to support works being required on the electrical network.

The above image highlights a situation which clearly highlights the incorrect method of supporting a live underground electrical cable.

The above image highlights a situation which clearly highlights the incorrect method of supporting a live underground electrical cable.

The inadequate level of support of the electrical network at this location was not acceptable to ScottishPower; the contractor was advised to support the exposed cable with caution to the correct ScottishPower requirements.

Given the ongoing mechanical excavations and the lack of adequate support, contact with the electricity network was a possibility the contractor was advised to contact ScottishPower EnergyNetworks Customer Connections department to progress a cable deviation to resolve the situation.

➡ Thorne & Derrick distributes Insulated Tools for the Rail & Utilities industries manufactured to British Standard BS 8020-2011.

The above image highlights a near miss situation which could have been easily avoided if the correct processes were implemented at the planning stage of the project, as opposed to attempting to rectify the avoidable situation at the construction phase.

On this occasion the project to construct an extension to an existing building had started, SP EnergyNetworks were contacted and advised the main contractor that the existing low voltage underground cable traversing through the foot print of the proposed extension would require to be deviated.

Further advice was delivered, highlighting that the existing cable should not be constructed over. The advice given was not adhered to and the contractors proceeded to excavate and install concrete foundations around the existing underground electrical network.

This course of action left the cable unprotected and open to the elements, the cable being concreted over at various locations and being supported in an unprofessional manor. During operations to excavate the foundations of the extension the electrical cable was damaged, fortunately on this occasion no injuries occurred to the operatives.

The above image demonstrates how not to support electricity cables.

The above image highlights a near miss situation which could easily have be avoided if the correct processes had been implemented at the planning stage of the project, as opposed to attempting to rectify the avoidable situation at the construction phase.

On this occasion the contractor progressed with the project despite being advised that a cable deviation would be required, and that the underground electrical network was not to be constructed over.

The contractor’s decision to progress construction placed operatives in danger which resulted in the low voltage cable being damaged. Despite the cable being damaged, excavations continued with the cable being exposed, covered in concrete and supported at various locations.

LV MV HV Voltage Detectors | Portable Earthing | Insulating Sticks | Insulating Gloves | CATU Electrical Safety Equipment

RAMS Generic Guidance For Supporting/Exposing/Operating Around SP EnergyNetworks Underground Distribution Electrical Cables:

33KV – High Voltage – Low Voltage Cables:

- Ensure all machine operators/site traffic drivers/operatives/visitors are made aware of all cable routes on construction site at initial site induction.

- Prior to works commencing, works area should be marked/highlighted (install signage at excavation location) to ensure all operatives are aware of the presence of the underground electrical network in the works area, this information also to be promoted continually throughout the remainder of the onsite works. (Task specific tool box talk also required prior to works commencing to ensure everybody understands the scope of works to be undertaken around the underground electrical network, their collective/individual roles to be clearly defined ensuring the required task is completed in a safe environment)

- Procure SP EnergyNetworks cable records (UMV System: Utility Map Viewer)

- Excavations as per HSG47 hand excavate to uncover all electrical cables/utilities in vicinity of proposed works.

- Supporting cables: If excavation length on electrical cables exceeds 1.2m cables will require to be supported.

- Install split cable ducting (150mm) around all exposed cables (for protection purposes only)

- No sudden movement of cables to take place. (minimum movement when placing split ducting around all cables)

- Provide substantial support beam above the cables, spanning across the exposed cable excavation, caution when placing/removing support beam. Ratchet straps are to be utilised to support the split ducted cables from the beam above.

- Ratchet straps to be of sufficient size/quality to support the weight of the split ducted cable, and are to be tensioned until they hold the ducted cables weight only, prevent any over strain on the ducted cables. Ratchet straps to be placed at 1m intervals.(Please note: no rope/string to be used to support underground cables)

- Once the ducted cables are sufficiently supported with the ratchet straps/supporting beam the hand excavation shall continue to clear 500mm beneath the existing cables. (Ensure the ducted cables will not sag at any exposed length of the cable)

- Cable records indicate no joints on cables at locus of proposed excavations, however if cable joints are located, excavation works to cease immediately and SP EnergyNetworks to be contacted for further guidance.

- Great care to be taken when installing the drainage pipe/other, that contact with the electrical network is avoided.

- Great care to be taken when installing/removing shoring/drag boxes etc that contact with the electrical network is avoided

- Caution to be taken when backfilling excavation around the existing cables, backfill to underside of cable, remove split ducting, sand cables with 150mm of sand, install marker tape.

- Continue to backfill with caution.

No SP EnergyNetworks cables to be supported at any time without SP EnergyNetworks authorisation. Contractors proposing to support the underground electrical network are to produce a risk assessment – method statement to formalise the advice described above to demonstrate to SP EnergyNetworks that risk assessments/method statements/safe systems of work will be implemented to ensure a successful conclusion to this stage of the project. The risk assessment/method statement shall be passed to SP EnergyNetworks for review/approval prior to excavation/supporting cable works commencing on site.

Cable Hangers | Cable Ducting | Cable Protection | Electrical Safety Equipment

Protecting Cables Against Strikes & Restoring Power Post-Strike

Thorne & Derrick have been distributors for 3M Electrical since 1985 and can provide a range of reliable and easy to install Cable Repair Products – this includes Scotch Tapes, Scotchcast Joints and Cold Shrink Tubes to provide effective re-instatement of cable sheath jackets on all types of LV MV HV cables in onshore and offshore locations with safe or hazardous area workplace classifications.

Cable Repair Products

Our range of cable protection covers manufactured by Centriforce provide underground utility protection of LV MV HV cables including Tapetile (11kV) and Stokbord (33kV 66kV 132kV) – contact us to discuss Cable Damage Prevention Products including Dectamesh, the underground detectable warning tape for alerting excavators of the presence of buried cables and to prevent potentially lethal accidents during excavation.