Cable Troughs & Troughing – A Network Rail Safety Alert

Published 30 Nov 2018

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

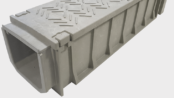

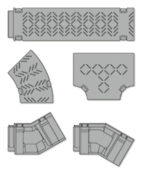

TTS Green Trough is fast becoming the cable management product of choice and installation on Network Rail infrastructure and rail cable protection where versatility and speed of installation of a cable trough is paramount.

The ground level or elevated polymer cable trough management system comprising troughs and lids conforms to Network Rail NR/L2/TEL/00013 for protection and management of trackside cables including LV Low Voltage and HV High Voltage signal, telecoms and power cables up to 25kV.

In May 2014, Network Rail issued Safety Bulletin 323 which prohibited with immediate effect the manual lifting, carrying and team handling of C143 conventional concrete troughs and troughing.

In January 2015, Network Rail issued Safety Bulletin NRB 15/01 mandating a risk assessment policy for all troughing products by using the MAC tool together with the troughing elements risk chart. On 22 April 2015 ORR issued the following Notices:

Prohibition Notice PN40/22042015 prohibiting “single individual employees or contractors manually lifting or carrying 10 or more units of cable troughs or troughing weighing 40kg or more in a 12 hours period” anywhere on Network Rail Infrastructure.

Prohibition Notice PN70/22042015 prohibiting “two employees or contractors manually lifting or carrying 10 or more units of cable troughs or troughing weighing 70kg or more in a 12 hours period” anywhere on Network Rail Infrastructure.

Both of the Prohibition Notices apply immediately. Continuing the activity would be a criminal offence.

A further Improvement Notice IN/25/22042015 requires Network Rail to undertake a suitable and sufficient assessment of the risk to employees, and contractors working under their control, from manually handling rail cable troughing weighing 25kg and more. That assessment will need to identify the measures necessary to control the risks identified.

This additional work is required by 25 October 2015. Further information will be communicated when the work is complete.

Immediate Action Required

- Compliance with the requirements of the Prohibition Notices is required immediately.

- If you are about to manually handle concrete troughing products then you must have an approved, site-specific risk assessment. If you haven’t then stop, request that a risk assessment is undertaken by a competent individual and implement any resulting actions before continuing work

- All staff and contractors who specify, manage, plan, authorise and carry out manual handling activities relating to the delivery, installation, renewal or disposal of troughing materials must comply in full with the guidance of the HSE manual handling MAC assessment tool or a suitable equivalent

- If your work involves any equivalent risk with other loads that you move manually, apply the same controls, derived from risk assessment.

Cable Troughs & Troughing

Selection Table

| Concrete Trough Variants | Description | Full Weight Concrete (kg) | Full Weight Half Length Concrete (kg) | Reduced Weight Concrete (kg) | Reduced Weight Half Length Concrete (kg) | TSS Green Trough Variants | Full Weight Polymer (kg) | Full Weight Half Length Polymer (kg) |

| C/1/6 | Straight Trough | 37 | 19 | 24 | 12 | TS120S | 6 | |

| C/1/7 | Straight Trough | 49 | 25 | 32 | 16 | TS150S | 8 | |

| C/1/38 | Transition | 50 | 25 | 35 | 18 | TT150/200 | 1 | |

| C/1/8 | Straight Trough | 71 | 36 | 46 | 23 | TS200S | 14 | |

| C/1/9 | Straight Trough | 55 | 28 | 36 | 18 | TS200S | 14 | |

| C/1/31 | Trough Bend | 55 | 28 | 36 | 18 | TS430B | 12 | |

| C/1/35 | Transition | 58 | 29 | 38 | 19 | TT200/250 | 1 | |

| C/1/10 | Straight Trough | 62 | 31 | 40 | 20 | TS250S | 9 | |

| C/1/34 | Trough Tee | 60 | 30 | 39 | 20 | TS250T | 10 | |

| C/1/36 | Transition | 65 | 33 | 44 | 22 | TT200/250 | 1 | |

| C/1/33 | Transition | 66 | 33 | 43 | 22 | TT250/300 | 2 | |

| C/1/29 | Straight Trough | 70 | 35 | 46 | 23 | TS300S | 16 | |

| C/1/82 | Trough Tee | 76 | 38 | 49 | 25 | TS430T | 21 | |

| C/1/32 | Transition | 77 | 39 | 53 | 27 | TT300/150 | 2 | |

| C/1/82 | Transition | 77 | 39 | 50 | 25 | TT300/430 | 2 | |

| C/1/61 | Transition | 82 | 41 | 53 | 27 | TT430/120 | 3 | |

| C/1/80 | Trough Tee | 83 | 42 | 54 | 27 | TS300T | 13 | |

| C/1/62 | Transition | 85 | 43 | 55 | 28 | TT430/200 | 3 | |

| C/1/44 | Transition | 88 | 44 | 60 | 30 | TT300/430 | 3 | |

| C/1/63 | Transition | 88 | 44 | 57 | 29 | TT430/250 | 3 | |

| C/1/23 | Trough Tee | 89 | 45 | 64 | 32 | TS200T | 9 | |

| C/1/45 | Transition | 94 | 47 | 60 | 30 | TT200/430 | 3 | |

| C/1/43 | Straight Trough | 115 | 58 | 75 | 38 | TS430S | 15 | |

| C/1/81 | Trough Tee | 140 | 70 | 91 | 46 | TS430T | 21 |

SE MAC Tool Assessment of Concrete & Polymer Trough Products

| GREEN | The risks are low but you should further assess the manual handling activity considering the time duration, repetitiveness of task and the site environment. | |

| AMBER | You should examine and assess the planned manual handling activities closely giving full consideration to alternative mechanical means. | |

| PINK | There is a high level of risk from manual handling of these products. A full re-evaluation of the risks is required prior to any further activity. | |

| PURPLE | There is a very high level of risk and manual handling of these products is prohibited unless a detailed risk assessment demonstrates that this may be performed safely. | |

| RED XX | These items are now effectively obsolete for manual handling compliance with the Network Rail prohibition notices. | |

TSS 90 Series | TSS 135 Series | TSS 200 Series | TSS 150 Series | TSS 300 Series | TSS 430

Thorne & Derrick

Thorne & Derrick are leading Specialist Distributors & Stockists of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment to the Rail industry.

Products: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

GRP Cable Trough | GRC Cable Trough | Concrete Cable Trough | Cable Ducting