Arc Flash Protection

IEC 61482-2 | Arc Flash Clothing & Protection Standard (Version EN-IEC 61482-2: 2020)

March 22nd, 2023EN-IEC 61482-2: 2020 Protective clothing against the thermal hazards of an electric arc

EN IEC 61482-2:2020 Supersedes IEC 61482-2:2009

IEC 61482-2 Standard is an International Electrotechnical Commission standard regarding live working – protective clothing against the thermal hazards of an electric arc. This part of EN 61482 specifies requirements and test methods applicable to materials and garments for protective clothing for electrical workers against the thermal hazards of an arc flash.

Electric shock hazards and other effects like noise, light emissions, pressure rise, hot oil, the consequences of physical and mental shock or toxic influences are not covered by this standard. Protection of eyes, face, head, hands, and feet against electric arc hazard fall outside the scope of this standard.

EN IEC 61482-2 includes two methods for testing. Garments can be certified according to one of the test methods or to both test methods.

What is an electric arc?

Electric Arc and the Arc Flash created is an extremely dangerous and least understood hazard of electricity. It occurs as a result of extreme discharges of voltage or electrical current from equipment including switchgear, transformers and heavy electrical equipment. The Arc generates a high level of energy for a very short span of time (up to 1 second). The intense heat can create temperatures as high as 19,000°C and it also produces electric shock, force and large quantities of thermal radiant energy.

What is the Risk?

In any situation where your employees are working with electricity, an Arc Flash can occur and as such the maximum energy of default circuits in any electrical installation must be able to be determined. The risks of an electric Arc exposure are:

- Electrocution – potentially fatal

- Extremely high levels of Radiant Heat

- 1st, 2nd or 3rd Degree burns – 3rd Degree burns cause permanent damage

Arc Testing Methods

EN-IEC 61482-1-1:2019 supersedes IEC 61482-1:2009 – “Open Arc Test Method”

USA Arc Flash Test Method

The Open Arc Test Method (ATPV test and garment test) determines the Arc Rating Arc Thermal Protection Value (ATPV level), ELIM (incident energy limit) or Energy Break Open Threshold (EBT) of flame-resistant material (Method A) and clothing (Method B). The basic principle is that the ATPV of the garment must be higher than the Arc Flash energy level as calculated. The “Open Arc” test method is the same as the original North American method for measuring the Arc Thermal Performance Value (ATPV) as used in ASTM F1959. The Arc Rating is expressed in cal/cm² (calories per centimetre square).

EN-IEC 61482-1-2:2015 – “Box Test Method”

European Arc Flash Test Method

In the Box Test Method, materials and clothing will be tested using two methods: the material box test method and the garment box test method.

The material box test method is used to measure and determine material response to an arc exposure when tested in a flat configuration. A quantitative measurement of arc thermal performance is made by means of the energy transmitted through the material. During this test, a fabric sample is exposed to an electric arc produced by a 4kA or 7kA short circuit. In this test, the arc does not last any longer than 500ms. The amount of heat transmitted through the sample is measured during and after the test.

Based on the resulting data and a Stoll curve, the length of time it would take to cause the onset of second-degree burns is subsequently determined. Samples are also assessed for after-flaming, hole formation, melting, etc.

The garment box test method is used to test the function of the protective clothing after an arc exposure (i.e., no heat flux will be measured). This test must be conducted on a complete garment. In doing this, the objective is not to determine the energetic value, but to assess the garment after exposure to an electric arc for defects in the seams, fastenings, and other closures.

The garments are tested and evaluated in two classes in the same test:

- APC1 (Arc protection class) protects against electric arc of 4kA (arc energy 168 kJ)

- APC2 protects against electric arc of 7kA (arc energy 320 kJ)

The standard requires the following:

- A garment must have at least an ELIM value of 3,2 cal/cm2 (130 kJ/m2), or else an ATPV or EBT value of 4 cal/cm2 (167.5kJ/m2) according to IEC 61482-1-1 or APC1 when tested according to EN IEC 61482-1-2

- Garments must be sewn with inherently flame-resistant threads

- If a garment has a higher rating of arc protection on the front than on the back, the garment’s torso, sleeves, and legs must be made using the arc-rated material; the back of the garment can have a lower arc rating

- Garments must have no exposed external metal (i.e., any internal metal or melting parts are to be covered inside to avoid contact with the skin)

- The garment label must show the lowest ATPV or class if the garment is comprised of different panels of material; more detailed information about areas of the garment with varying levels of protection may be provided on the garment’s label or in the manufacturer’s instructions pertaining to use

- The protective clothing material must have some minimum tensile, tear, and burst resistance and minimum dimensional stability (e.g., for wear and tear associated with cleaning)

- The garments must cover the entirety of the wearer’s body. For example, jacket and trousers must be worn together with other personal protective equipment (PPE), including a helmet with a protective visor, protective gloves, and protective footwear (i.e., work boots) to achieve the correct level of protection. Layering is very important and will increase protection (e.g., if you wear flame-retardant underwear beneath your flame-retardant garments, you are better protected).

ARC FLASH PPE & ELECTRICAL SAFETY

Main UK Stockists & Distributors of Electrical Safety Products

Thorne & Derrick provide Electrical Safety Equipment to substation engineers, cable jointers, overhead linesmen and utility workers with PPE and electrical safety equipment including insulating gloves, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out maintenance on LV-HV switchgear, substations, cables and electrical equipment.

We protect substation engineers, asset managers, SAPS, cable jointers, overhead linesmen and utility workers with PPE and safety equipment: this includes insulating gloves, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out repair and maintenance on LV-HV switchgear, transformers, substations and turbines.

All our Cable Connection & Energisation Accessories including Medium & High Voltage joints, terminations, connectors and cleats are tested to the latest international standards and supporting ranges of professional cabling tools are stocked to reduce incident, accident and downtime to plant and people.

Ten Most Common Errors in Arc Flash Studies | Guest Article By Power EasyPower LLC

June 20th, 2022

Ten Most Common Errors in Arc Flash Studies

- Special thanks to Emily Sotupo Marketing Co-ordinator from EasyPower LLC for the kind permission to republish – view the original article click here

Arc Flash Studies

Each year we see dozens of arc flash studies ranging from first attempts to submittals from seasoned veterans in the industry. With an eye towards improving the overall results in the field, we offer this list of “Ten Most Common Errors.” This is not a criticism of anyone or any group; it is more of an effort to bring some insight to areas that may not be that well understood, including changes in the standards, the phenomenon of arc flash, and the application of analytical tools toward that end.

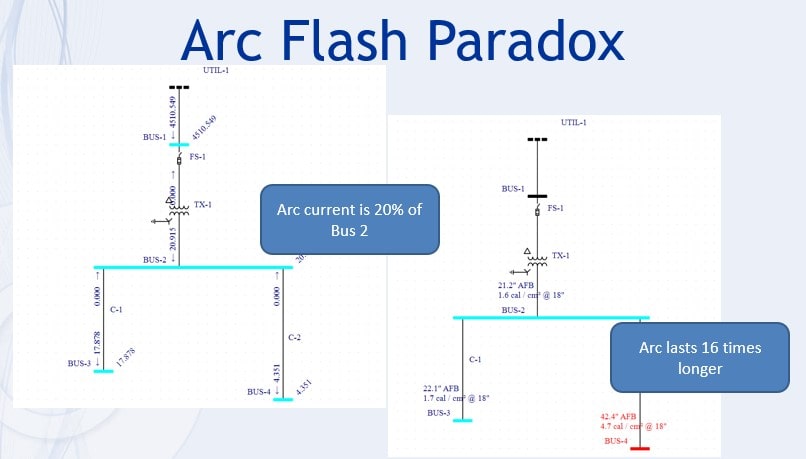

#1 – The Lack of Understanding the “Arc Flash Paradox.”

The counter-intuitive nature of the arc flash hazard tends to impede the acceptance of arc flash as a hazard by some of us with a long history in the industry. Put simply, within the same system you can have buses that have high current and high arc incident energy AND other buses that have lower current but that calculate a higher arc incident energy. Incident energy has a significant relationship to the time required to clear the arc.

Comparing Bus-4 to Bus-2 in the example below, Bus-4 has a higher incident energy in spite of having available fault current at Bus-4 that is only 20% of the fault current available at Bus-2. The length of time to clear the arc in this case has a significant bearing on the arc flash calculation.

#2 – “Infinite source” is Not the Worst Case

Nor should it be used in place of actual utility data when calculating arc flash results. Often times, the local utility company cannot or does not respond to a request for short circuit data as required for an arc flash hazard assessment. From the early days of power system design, the engineer responsible for the electrical system was tasked with the requirement to have the system be able to safely protect itself against the worst-case short circuit current that it could possibly see from the utility source. The concern was due to the short circuit rating for each piece of equipment in the system.

Each piece of equipment needed to be able to survive in the case of a short circuit fault. The results of an equipment duty analysis will determine if any system element has the potential for being over-stressed in the case of a worst-case fault at that location.

In that case, using an infinite source would be valid to determine system integrity. In the case of arc flash analysis, however, the use of a higher short circuit current value than is really expected could potentially yield a lower result for arcing incident energy since the higher current value of the infinite source would cause the protective devices to trip quicker than the same circuit exposed to actual or estimated fault current at the utility connection. This can be shown in the framework of an EasyPower study by using the Scenario Manager to compare results.

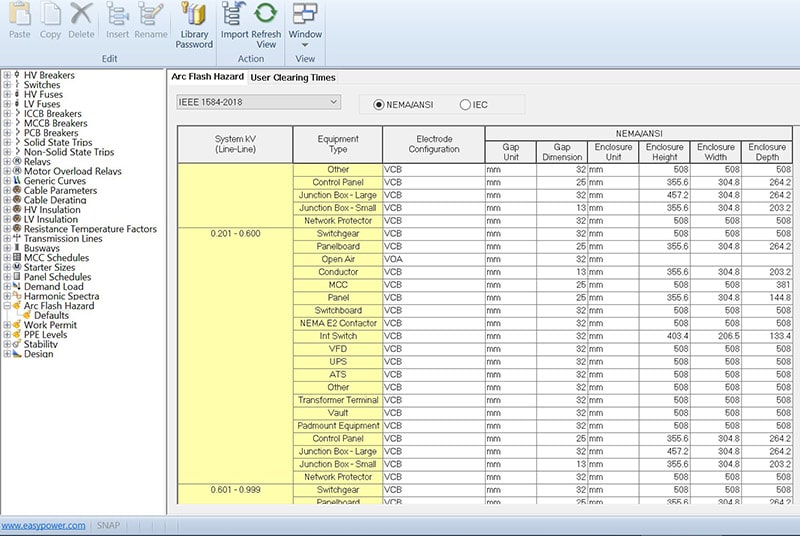

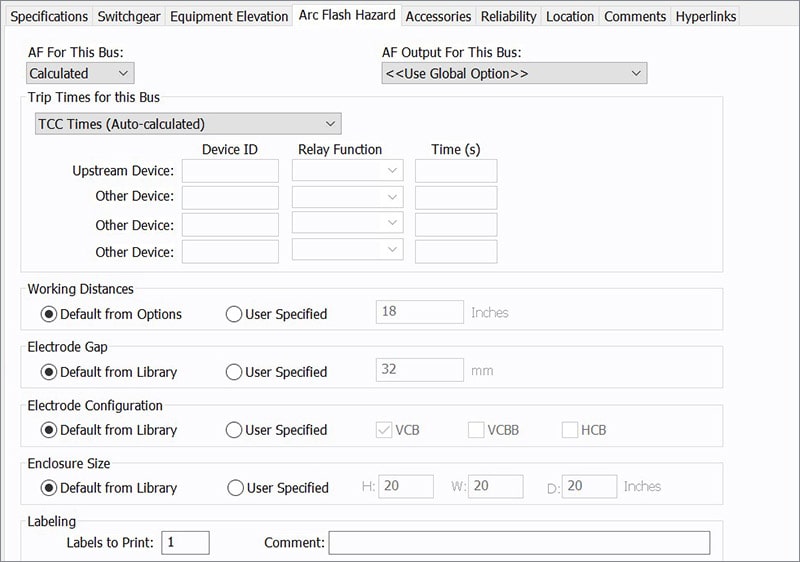

#3 – Not all buses are created equal!

The long-awaited release of IEEE 1584-2018 promised improved alignment between model results and the test data upon which the model is built. Part of this improvement is the inclusion of a number of parameters that were not included in the original arc flash calculation method. Included in the updated standard is a table of typical values for each of these parameters along with equipment type and different voltage levels.

It is therefore a good practice to ensure that the data collection team can identify the type of switchgear or panelboard and at the same time recognize if there is a significant difference between the typical values listed in the standard and record the actual values for:

- Working distance

- Electrode gap

- Enclosure size

- Electrode configuration

In EasyPower, the default values for each of these parameters are included in the Arc Flash Hazard Default table in the Device Library. If the actual system diverges from the default values significantly, it is incumbent on the person creating the digital model of the system to update the recorded values during model creation.

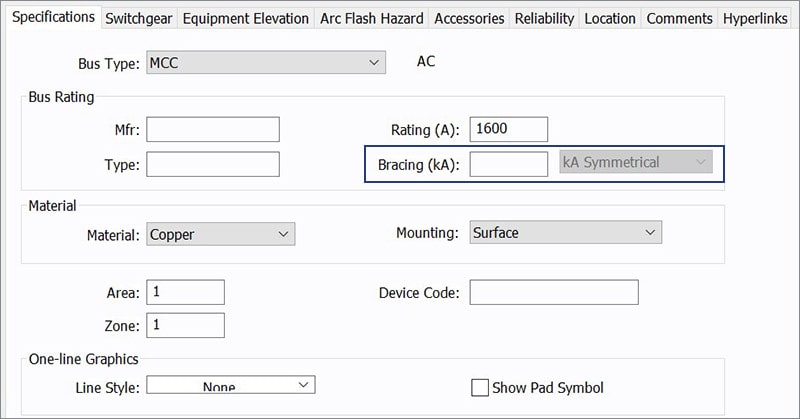

Arc Flash Hazard Default Values

Typical Parameters in the Arc Flash Hazard Tab

#4 – Why Not Put 6 Inches Working Distance on the Label, Since That is What My Hand Will See?

It is expected that the results of the arc flash study will be reviewed by management with an eye towards verifying that all hot work required in the plant will be necessary and conducted with the utmost focus on employee safety.

As such, all hot work should be conducted under the auspices of properly completed Hot Work Permit. Labels do not authorize hot work. The working distance on the label is generally based upon the distance from the bus to the head or thorax of a worker while the panel cover is being removed. It is really a convenient number to permit the qualified worker to understand the relative magnitude of the hazard when the cover is removed. Additional information on the label is discouraged to prevent any misunderstanding of this restriction.

#5 – Why Calculate Equipment Duty on Plant Equipment That Has Already Been in Operation For 25 Years?

If it has been working for that long without an issue, why bother? Right? SCCR (short circuit current rating) is the maximum short-circuit current an electrical component can safely withstand without causing shock or fire hazard. In general, the SCCR for electrical switchgear or panels is based on the lowest component’s SCCR in that panel. Protective devices included in the one-line diagram must be linked to the datasheet for that element located in the Device Library.

As long as the one-line element is linked to the Device Library (meaning it is verified using the Calculate button on the Short Circuit tab of the Data dialog box), EasyPower calculates the equipment duty during a short circuit analysis.

The withstand rating of switchboards, panels, and MCC enclosures is usually listed on the nameplate of the installed element. In EasyPower, this rating should be entered in the dialog box for the element to be included in the equipment duty calculation.

Consideration should be given to system changes over the life of the installation. Changes in load size and location, increases in fuse sizes, breaker trip settings, as well as unannounced changes in utility short circuit values could render the original system design guard bands inadequate. Even if the SCCR for some elements may not have been entered during the original arc flash study, it seems prudent to include the data during study updates.

Bus Bracing Missing in the Data Dialog Box for an MCC

#6 – We Do Not Need a Coordination Study on Protective Devices During This Update. We Did It Five Years Ago

You may be correct unless:

- Some blown fuses were swapped out with a different manufacturer’s product or values because they were available during urgent times.

- Relay or LVPCB trip settings were tweaked to eliminate nuisance tripping.

- Large system loads have been added, moved, or deleted.

At a minimum, you should check the Sequence of Events. PowerProtector™ is the name of the EasyPower module used for plotting TCC curves and verifying coordination. When system fault current is displayed during a single bus fault, EasyPower illuminates an icon labeled Sequence of Events.

A simple click on that icon displays the chronological trip order of all device between the faulted single bus and the energy sources affected, providing a quick and efficient way to verify device coordination.

Arc Flash Protection & Electrical Safety Products | Distributed By Thorne & Derrick

#7 – I Always Calculate Arc Incident Energy Including the Main Breaker Because I Don’t Think It Will Fail

The IEEE 1584 standards (both 2002 and 2018) recommend excluding the main breaker of a panel or switchgear when there is not an arc barrier between the incoming conductors to the main breaker and anyone working downstream on the main bus. The reason has less to do with the reliability of the breaker itself and is more based on the fact that once established, an arcing fault will produce a plasma ball, often several millimeters in diameter.

If that plasma ball contacts any electrified bus work, the arc can propagate and potentially render the protective device useless. Verifying the existence of an arc barrier between the incoming conductors and the downstream bus is the only way to recommend including the main breaker.

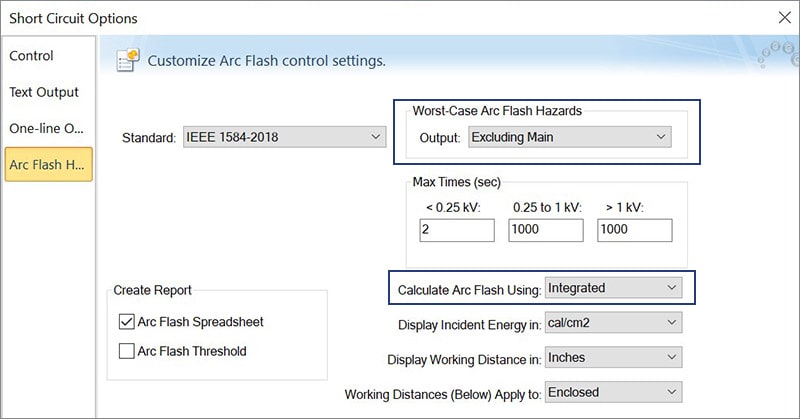

Worst-Case Arc Flash Hazards Indicating the Option to Exclude Main Breaker and Use the Integrated Method to Calculate Arc Flash

#8 – Half-cycle (Momentary) Current is the Worst-case Fault Current, so I Use It to Calculate Arc Incident Energy

Recognizing that the available fault current may change over time, IEEE 1584-2018 recommends that a dynamic assessment of fault current be used to accommodate changes that may be the result of reducing motor contribution, load drops, or other changes in fault current. In EasyPower, the recommendation is to use the Integrated Method.

In the EasyPower Integrated Method, during:

- The first cycle of the fault, momentary current is used for energy integration.

- The next 8 cycles, interrupting (5-cycle) current is used to calculate energy.

- For any additional time to clear the protective device, 30-cycle current is used.

9 & 10 Deal with labels, which are the source of a large number of frequent errors. These are two of the most frequent:

#9 – I Want My Labels to Show the HRC #, in Spite of the NFPA 70E Changes

NFPA 70E revision history includes the following changes:

- The 2012 version had Hazard Risk Category (HRC) tables.

- The intent was to calculate incident energy and then use the table to determine the PPE needed.

- The 2015 version changed HRC to PPE category.

- The label may have calculated Incident Energy OR PPE category, but NOT BOTH.

- Allows for a “Site Specific” option for companies to define their own categories.

- The 2018 version repeats label restrictions.

- The industry is migrating to align training for labels and PPE rating to reflect the incident energy.

While the standard is voluntary, the industry is moving to align with the NFPA 70E recommendations to label PPE with incident energy. So, the reasons (if any) to stay with using the HRC # on labels should be reconsidered. We recommend:

- Set a timetable to achieve NFPA 70E alignment.

- Decide between Site Specific or Incident Energy to determine PPE.

- Update the safety manual and training to follow NFPA 70E.

#10 – I Want to Put Maintenance Mode incident Energy on the Label

For at least the last 10 years, hardware companies have made available a feature that enables the user to temporarily set the trip time of a relay or LVPCB unit to be much quicker and provide a safer, lower arc hazard on the protected bus. This feature can be enabled by a switch on the front panel or an electric control signal routed to the back of the panel and is called Maintenance Mode.

This is a method of hazard reduction preferred over just adding more PPE for the worker at the higher energy level. It also falls into the category of hot work. Therefore, the information should not be on a label. Instead, the maintenance procedure, correct PPE, and instructions to use the Maintenance Mode feature should be approved and listed on the Hot Work Permit.

EasyPower LLC – Bio

Since our inception in 1984, we’ve been redefining how companies manage, design, and analyze their electrical power distribution. We continue to develop unprecedented technologies to make it simpler, smarter, and safer— driven by an unyielding commitment to deliver cutting-edge power system software that’s inherently easy to use.

Organizations throughout the world use our advanced— yet simple— software tools to safeguard their valuable resources of time, money, and personnel. Oil refineries, power utilities, paper and pulp manufacturers, military installations, data centers, and a host of others rely on EasyPower to keep their power systems running safely and smoothly.

From plant personnel to the most experienced electrical engineers, EasyPower users continually rave about its simplicity and power.

Our family of products includes the EasyPower® suite, ArcFlash Essentials™, and OnSite™, as well as our grounding calculation solution, XGSLab, for which we are the exclusive reseller in the United States and Canada. We also provide training for EasyPower and electrical safety in general, in addition to offering a full range of engineering services.

EasyPower Customer Service

EasyPower’s Sales Team is available to meet all of your customer service needs:

- Provide free demos

- Provide pricing information

- Customize a software package to meet your specific engineering needs

- Provide answers regarding upgrades, maintenance contracts, and key replacements

If you need Engineering Services, we are happy to process your Request for Proposal from our Consulting Team. Or, if you have Training Questions, we’ll gladly answer those as well.

Contact us by email at [email protected]

Contact us electronically by using our Contact Form, or reach us with our address or phone number here:

EasyPower LLC

15862 SW 72nd Ave, Suite 100

Portland, OR 97224

+1 (503) 655-5059

Arc Flash PPE & Electrical Safety

Main UK Stockists & Distributors of Electrical Safety Products

Thorne & Derrick provide Electrical Safety Equipment to substation engineers, cable jointers, overhead linesmen and utility workers with PPE and electrical safety equipment including insulating gloves, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out maintenance on LV-HV switchgear, substations, cables and electrical equipment.

We protect substation engineers, asset managers, SAPS, cable jointers, overhead linesmen and utility workers with PPE and safety equipment: this includes insulating gloves, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out repair and maintenance on LV-HV switchgear, transformers, substations and turbines.

All our Cable Connection & Energisation Accessories including Medium & High Voltage joints, terminations, connectors and cleats are tested to the latest international standards and supporting ranges of professional cabling tools are stocked to reduce incident, accident and downtime to plant and people.

Arc Flash Risk In Wind Turbine Renewables?

April 19th, 2022

Caring & Maintaining Arc Flash Clothing by CATU Electrical

April 14th, 2022

Heavy-Duty Arc Flash Clothing

Industrial Washing & Drying

Maintaining Arc Flash Clothing For Long Term Multi-Risk Protection

The CATU range of Arc Flash Clothing Kits are comfortable, lightweight and range from 12 cal/cm² – 40 cal/cm². The Pro Kit gathers a selection of essential garments to guarantee protection against electrical arc risks – should you require guidance on selection and use of an Arc Flash Calculator please call Thorne & Derrick.

Thorne & Derrick stock and distribute an extensive range of arc flash clothing and protection available in a range of sizes and cal ratings to ensure protection against the dangers and risks of arc flash hazards manufactured by market-leading specialists CATU.

The CAT’ARC range now offers multi-risk and Arc-Flash protection from 12 to 40 cal/cm². These comfortable garments are worn on a daily basis and therefore need to be cleaned regularly. CATU helps you to maintain their protection levels, even after many washes.

Technical and innovative, the 12 cal/cm² CAT’ARC garments have been tested according to the ISO 15 797 standard, which certifies that they retain their properties throughout their period of use. This standard verifies that our garments support global industrial maintenance solutions offered by service providers, such as professional laundries.

The arc flash protective garments were subjected to 50 wash cycles at 75 ° C and drum drying at 70 ° C – this makes it possible to check the maintenance of the different protections, the dimensional stability, the behaviour of the colours, the wrinkling, the formation of creases, the pilling and the visual.

12 Cal Arc Flash Protection Kit

-

-

-

- Flame spread (ISO 11612 – A1 A2)

- Source of heat emmited by convection, radiation, or contact

- (ISO 11612 B1, C1, F1)

- Molten metal spatter (ISO 11612 E2)

- Protection against welding hazards (ISO 11611 class 2)

- Electrostatic dissipation (EN 1149-5)

- Arc-Flash resistance

- box test (IEC61482-1-2 / Box Test APC 1)

- Mechanical strength (tensile, tear)

-

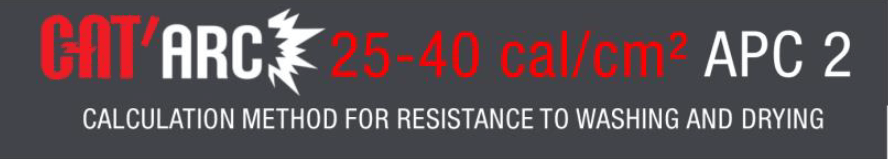

-

The innovative CAT’ARC 25-40 cal/cm² fabric has been subjected to 50 complete wash cycles at 40°C and tumble drying at 60°C, in accordance with ISO 6330, Household Washing and Drying Methods for Textile Testing. This standard verifies that our garments can withstand the care solutions. Thus, the fabric has been tested and validated after 50 industrial wash-dry cycles for the following performances:

25-40 Cal Arc Flash Protection Kit

-

-

-

- Flame spread (ISO 11612 – A1 A2)

Source of heat emmited by convection, radiation, or contact - (cf ISO 11612 B1, C2, F2)

- Protection against welding hazards (cf ISO 11611 class 2)

- Electrostatic dissipation (EN 1149-5)

- Arc-Flash resistance

box test (IEC61482-1-2 / Box Test APC 2) - Mechanical strength (tensile, tear)

- Flame spread (ISO 11612 – A1 A2)

-

-

Caring & Maintaining Arc Flash Clothing

Some Tips On How To Care For Your Garment

As a reminder, the useful life of clothing depends on the use of the PPE, maintenance, storage, etc. it is therefore important to take good care of your clothing and adapt the frequency of washing to the working conditions and the degree of soiling. To wash your garment properly, there are a few simple tips to follow:

- Close all hook and loop fasteners and zips. Empty all pockets.

- Turn the arc flash garment inside out to avoid damage from rubbing against the machine drum.

- Wash separately the arc flash clothing. Do not mix with ordinary garments without similar protective properties.

- Recommended washing temperature: 40°C (104ºF).

- Do not bleach the clothing.

- Tumble dry possible at 60ºC (140ºF)

Arc Flash PPE & Electrical Safety

Main UK Stockists & Distributors of Electrical Safety Products

Thorne & Derrick provide Electrical Safety Equipment to substation engineers, cable jointers, overhead linesmen and utility workers with PPE and electrical safety equipment including insulating gloves, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out maintenance on LV-HV switchgear, substations, cables and electrical equipment.

We protect substation engineers, asset managers, SAPS, cable jointers, overhead linesmen and utility workers with PPE and safety equipment: this includes insulating gloves, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out repair and maintenance on LV-HV switchgear, transformers, substations and turbines.

All our Cable Connection & Energisation Accessories including Medium & High Voltage joints, terminations, connectors and cleats are tested to the latest international standards and supporting ranges of professional cabling tools are stocked to reduce incident, accident and downtime to plant and people.

Arc Flash Protection & Electrical Safety | 15 Measures to Mitigate the Hazards of Arc Faults

April 12th, 2022

Arc Flash Protection & Electrical Safety Products | Distributed By Thorne & Derrick

Arc flash Protection

An arc flash is the light and heat produced as part of an arc fault; a type of electrical explosion or discharge that results from a low impedance connection through air to ground or another voltage phase in an electrical system.

In industries working around high and low voltage electricity, the importance of Electrical PPE and arc flash protection is widely recognised, and the latest electrical safety requirements are understood by managers and operatives alike.

However, the dangers posed by an arc flash are not so well known in comparison. With temperatures of up to 35,000ºF, which is more than four times hotter than the surface of the sun, an arc flash has the potential to burn an operative’s skin within fractions of a second, meaning PPE really is the last line of defence for workers.

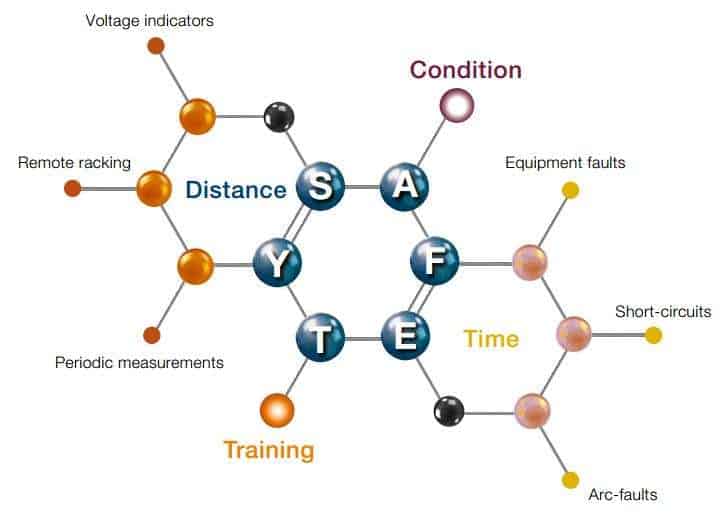

In the face of the internal arc fault risk present in low and medium voltage switchgear, prevent accidents to protect the personnel and the electric installation itself by following this proven formula.

Condition

Knowing and improving the condition of the equipment is a key factor in reducing the likelihood of failure, damage, and injury. is comprised of condition, distance, time, and training.

- Risk Assessment study – Asset risk assessments to establish the risk profile of equipment based on its condition and importance in the system, and prioritize actions to mitigate the risk before the hazard occurs

- Monitoring programs – Risk monitoring and mitigation programs to maximize improved reliability and reduced operator exposure

- Upgrades and retrofit – Equipment upgrades and retrofit which decrease operator exposure because of reduced maintenance, faster cycle times, and lower clearing times

- Diagnostic testing – Diagnostic testing to address concerns of bad connections, pollution, mechanical faults and minimize failures due to defective devices

Distance

Maintaining a safe distance between personnel and equipment during critical operations provides the most effective means of avoiding injury by keeping people out of harm’s way

- Remote racking – Remote racking provides a safer operating environment for personnel through the proven method of adding distance between the operator and arc flash incident energy at the switchgear site, bringing operation of power circuit breakers to a new level of safety. ABB vacuum circuit breakers can be provided with a fully integrated motor operated racking system for their use in new replacement switchgear or as part of the hard-bus and cradle-in-cradle retrofill solutions.

- Voltage indicators – The installation of voltage indicators on accessible power circuits can increase the operators safety and avoid accidental electrical contact injuries. VisiVolt is an ABB passive voltage indicator perfectly suiting the equipment upgrade. It is adapted for permanent installation on busbar and naked or insulated metal conductors, indicates the presence of voltage by displaying a large and well visible lightning arrow sign on its display. The relevant silicone elastomeric enclosure ensures performance also in outdoor conditions while its fluorescent orange colour provides good visibility among the other elements of the system.

- Infrared thermo-graphic inspection – Infrared (IR) thermal measurements are performed through dedicated arc-proof ports with power compartment doors closed. The periodic thermo-graphic inspection of the critical areas (e.g. power cables connections) is an efficient method for preventing associated faults. Ports can be added to existing switchgear by ABB expert engineers keeping the original equipment design characteristics.

- Partial discharge measurements – Periodic measurement of the partial discharge (PD) level is a proven method for detecting insulation degradation before real insulation failure develops. The assessment results are documented as trend curves for each switchgear compartment, where the curves with high increase of partial discharge activity level indicate compartments with high risk of insulation failure. Site work is performed with closed doors.

Time

Reduction of time for clearing fault conditions has a dramatic impact on the energy released and consequent damage and injury.

- MV equipment faults: relay upgrades with Relion® – microprocessor equipment which operate faster than electromechanical relays and support faster clearing times.

- Short-circuit current: Is-Limiter device – Is-limiter device as a fast operating interrupting device that limits the short circuit current to a level that breakers and buses can withstand, protecting property and personnel. Replacement of existing switchgear and cable connections with new equipment with higher short-circuit ratings can be technically impossible. The use of Is-limiters reduces the short-circuit current in extensions of existing systems and in new systems. The Is-limiter is capable of detecting and limiting a short-circuit current during the first current rise in less than a millisecond.

- Arc-faults: REA arc fault detection system – REA arc flash protection relay uses patented fiber-optic sensor technology that instantaneously detects light from an arc to signal a “trip” to the designated circuit breaker in less than 2.5 ms, minimizing an arc flash incident.

- Arc-faults: Upgrade with UFES – UFES, an ultra fast earthing switch, provides detection and grounding of faults in times significantly faster than breaker clearing times, leading to the avoidance of injury and damage and the reduction of production outages. A device as small as an insulator offers enhanced protection for your switchgear by the effects of internal arcs. The UFES arc protection system channels the uncontrolled release of energy by the arc into a solid metal, 3-phase connection to earth potential. The internal arc will be extinguished within an operation time of < 4ms after detection of the fault.

Training

Adequately trained personnel and proper procedures are essential to safe operations

- Personnel training – Training engineering and technical services provide personnel with a better understanding of their equipment and systems and the safest means to operate them.

- Procedure development – Arc flash studies help to determine the necessary level of protective equipment or clothing (PPE) to be worn by workers in close proximity to potential arcs and also help determine the proper application of any arc flash protection equipment to be installed.

- Engineering studies – Engineering studies determine the proper settings and system coordination, while addressing the speed of the system to handle a fault so relays and associated protective devices are set properly in order for the system to react as designed.

Electrical Safety Providers

We protect substation engineers, asset managers, SAPS, cable jointers, overhead linesmen and utility workers with PPE and safety equipment: this includes insulating gloves, arc flash clothing, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out repair and maintenance on LV-HV switchgear, transformers, substations and turbines.

All of our Cable Connection & Energisation Accessories including Medium & High Voltage joints, terminations, connectors and cleats are tested to the latest international standards and supporting ranges of professional installation tools are stocked to reduce incident, accident and downtime to plant and people.