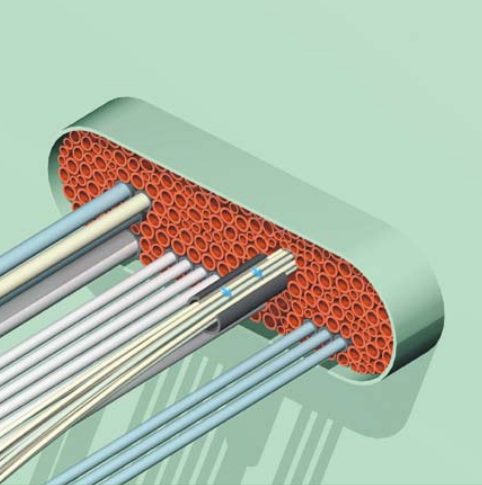

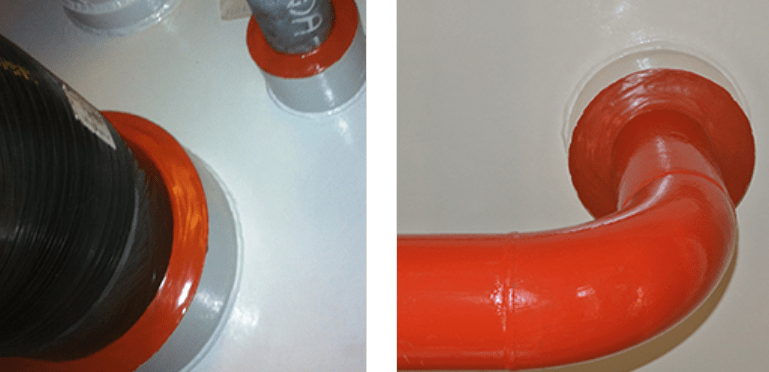

In collaboration with CSD Sealing Systems, Thorne & Derrick offers an extensive range of duct seals designed to deliver gas-tight, watertight, fire-resistant and rodent protection sealing for cable duct entries and pipe penetrations in industrial and hazardous area Zones in both onshore and offshore solutions.

Fire Rated Sealing Systems & Protection Defined

Offshore fire ratings, including A0, A60, H0, H60 & H120, are industry classifications that determine the ability of cable and pipe penetration sealing systems to withstand fire in potentially explosive atmospheres and hazardous area locations (Zone 1 & Zone Flammable Gas). The “A” classification is associated with resistance to cellulosic fires, while the “H” classification pertains to protection against hydrocarbon fires in offshore locations.

A0 – Classification used to indicate that a cable or pipe seal can resist flames and smoke for up to 60 minutes without insulation protection against heat

A60 – Classification withstands a cellulosic fire for up to 60 minutes while maintaining structural integrity and preventing the spread of flames and smoke

H0 – Classification used to indicate that a cable or pipe seal will provide 120 minutes of stability and integrity against a hydrocarbon fire, but no insulation

H60 – Classification used to indicate that a cable or pipe seal will provide integrity and stability for 120 minutes and provide insulation for 60 minutes, in the event of a hydrocarbon fire

H120 – Classification used to indicate that a cable or pipe seal can resist a hydrocarbon fire for up to 120 minutes

Pipe Penetration Sealing System Benefits

CSD NOFIRNO

- Simplified design achieved through the standardisation of all bulkhead penetrations, significantly reducing the number of sealing components

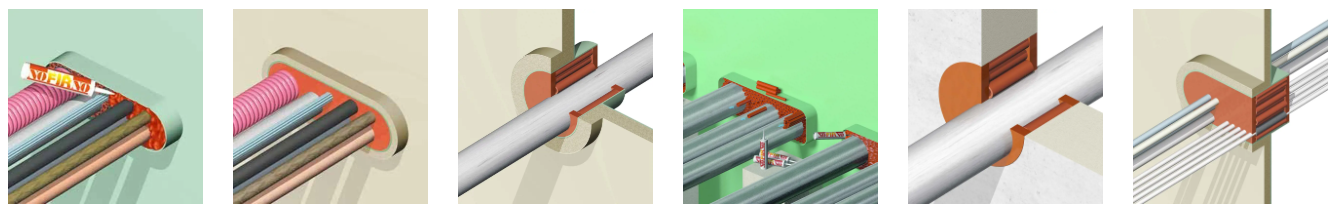

- Design modifications can be implemented without requiring additional hotwork in hazardous area locations where flammable gas is a potentially explosive atmosphere risk

- Reduced space requirements for more efficient sealing system design

- Faster cable or pipe sealing installation process, saving time and labour costs

- Allows for pipework misalignment due to build tolerances, improving flexibility

- Substantial reduction in the number of pipe spools needed using CSD NOFIRNO

- Reduced vibration stress and cathodic corrosion, extending the lifespan of pipe systems and lowering failure rates

- Simplified pipe sealing system replacement, improving maintenance efficiency

- Lower vibration and noise levels, reducing the system’s overall noise signature

- Significant weight savings compared to traditional bulkhead fittings, leading to enhanced energy efficiency and advanced seal performance

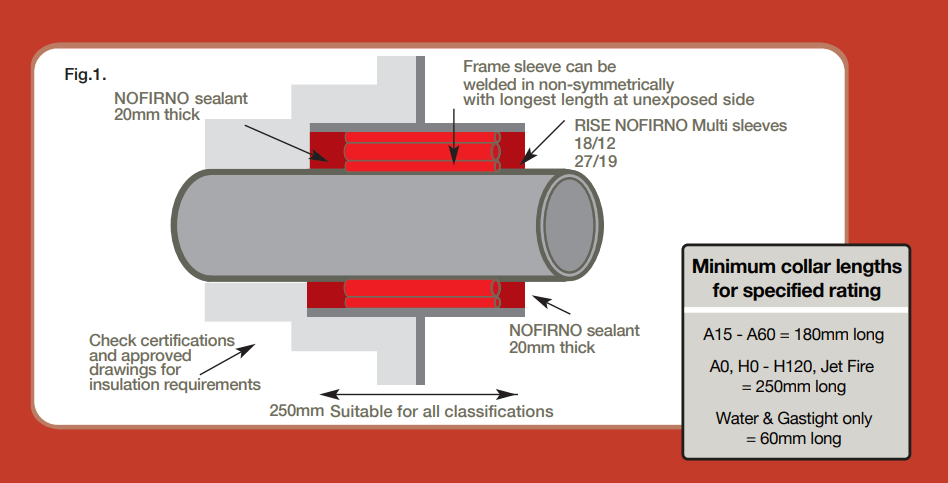

Enhanced Survivability

- Certified for use in A60 boundaries (minimum length of 180mm), tested and approved for A0 applications without insulation (minimum length of 250mm)

- Proven watertight performance even after passing the A60 fire test

- Successfully passed a 2-hour hydrocarbon fire test, both with and without insulation, with ratings of H0 and H120

- Endured a 2-hour jet fire test without the need for additional insulation

- Shock tested to 850g in accordance with DEF STAN 08-120, followed by a post-test pressure test at 6.9 bar

- Blast resistant pipe penetration sealing systems for offshore locations

- Compliant with low smoke and toxicity standards (DEF STAN 02-711 and DEF STAN 02-713)

Flexible Pipe Penetration Sealing System

For A0 – A60, H0 – H120, Jet fire, Blast, Watertight & Gastight Ratings