Marconite

Marconite – Electrically Conductive Aggregate Material

Earthing Compound

Contact us for Marconite | Large Stocks | Competitive Prices | UK & Export Sales

Marconite is the world’s premium electrically conductive aggregate material – the synthetic material is manufactured specifically for use in earthing applications and unlike Bentonite, it is not a naturally occurring mineral or ore.

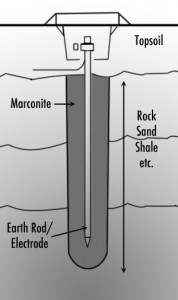

Marconite enables electrical earthing system designers and installers to achieve permanent, stable and low resistance earthing solutions, even in difficult ground conditions when used as a backfill to enhance the effects of copper earth electrodes or earth rods.

Specifically developed and manufactured for the needs of the earthing industry, Marconite has allowed engineers for over 40 years to tackle the toughest conditions and achieve the satisfactory earthing of installations including substations across the globe.

Dark grey in colour and of a granular consistency, Marconite earthing replaces traditional sand and aggregate materials. The mix ratios should be 3 parts of Marconite to 1 part cement by weight with the addition of 1 litre of water per 4 Kg of total mix. For example:

- 3 x 25 Kg bags of Marconite

- 1 x 25 Kg bag of Cement

- 25 litres (25 Kg) of Water

When mixed as described above Marconite forms a relatively dry material with an ‘as poured’ density of around 1300 Kg / m³. The water content may be adjusted as the application requires but this will affect the concretes final compressive strength and the drying times accordingly. Typically, Marconite concretes are touch dry within hours but can be several days before being fully cured.

Marconite is also available in the form of a ‘premix’ – this is a standard 25 Kg poly sack which contains pre-weighed amounts of Marconite and cement powder in the correct ratio to form the preferred concrete.

With the addition of 5 litres of water each Marconite bag can then be mixed independently and used without the need to carry additional cement powder – contact us for further information.

MARCONITE – THE BENEFITS

- Low resistivity : 0.001 ohm.m is extremely low (Bentonite 3 ohm.m)

Marconite is a granulated electrically conductive aggregate which replaces sand in mixes with cement, thereby providing electrically conductive concrete.

- Versatile : suits most ground conditions and becomes a permanent, solid structure that it is not prone to shrinking, drying out or being washed away

- Cost effective : permanent solution with no need to remove and replace or ‘maintain’ periodically with additional water / salts in order to achieve the desired earth values

- Chemically inert : Marconite is non-corrosive to steel or copper, does not attack cement structures and has a pH within the neutral range

- High strength : can be used as part of the building structure itself and achieve strengths higher than Grade 25 concrete

- Easy to use : forms a concrete like material achieving a low resistance earth, no need to wait or return to test

What Makes Marconite Unique?

Other earthing materials marketed as conductive aggregates include low grade carbonaceous by-products from other industries which include coal, metallurgical coke, power station clinker, carbon black, Bentonite and others. All of these products can be called conductive with resistivity of 5 ohms metres.

The resistivity of Marconite is in the order of .001 ohm metres. When mixed with cement the resulting conductive concrete is still only 0.19 ohm metres.

This is significantly lower than Bentonite for example, which has a typical resistivity of 3 ohms metre upwards.

Typically the above products can include anything between 15-20% impurities which are corrosive and will corrode earth connections resulting in the loss of the system which can prove to be very, very expensive.

The compound has no such impurities and at PH7 is non corrosive and is manufactured specifically for earthing, it is not a by-product.

Calculating Volume Of Marconite Required

Table 1 – Weight Quantity in kilograms (kg)

| Depth (cm) | Hole Length & Width | |||||||||

| 10 x 10cm | 20 x 20cm | 30 x 30cm | 40 x 40cm | 50 x 50cm | 60 x 60cm | 70 x 70cm | 80 x 80cm | 90 x 90cm | 100 x 100cm | |

| 10 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 |

| 20 | 20 | 40 | 60 | 80 | 100 | 120 | 140 | 160 | 180 | 200 |

| 30 | 30 | 60 | 90 | 120 | 150 | 180 | 210 | 240 | 270 | 300 |

| 40 | 40 | 80 | 120 | 160 | 200 | 240 | 280 | 320 | 360 | 400 |

| 50 | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 |

| 60 | 60 | 120 | 180 | 240 | 300 | 360 | 420 | 480 | 540 | 600 |

| 70 | 70 | 140 | 210 | 280 | 350 | 420 | 490 | 560 | 630 | 700 |

| 80 | 80 | 160 | 240 | 320 | 400 | 480 | 560 | 640 | 720 | 800 |

| 90 | 90 | 180 | 270 | 360 | 450 | 540 | 630 | 720 | 810 | 900 |

| 100 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

Table 2 – Bag Quantity in amount of 25kgs bags required

| Depth (cm) | Hole Length & Width | |||||||||

| 10 x 10 cm | 20 x 20 cm | 30 x 30 cm | 40 x 40 cm | 50 x 50 cm | 60 x 60 cm | 70 x 70 cm | 80 x 80 cm | 90 x 90 cm | 100 x 100 cm | |

| 10 | 0.4 | 0.8 | 1.2 | 1.6 | 2 | 2.4 | 2.8 | 3.2 | 3.6 | 4 |

| 20 | 0.8 | 1.6 | 2.4 | 3.2 | 4 | 4.8 | 5.6 | 6.4 | 7.2 | 8 |

| 30 | 1.2 | 2.4 | 3.6 | 4.8 | 6 | 7.2 | 8.4 | 9.6 | 10.8 | 12 |

| 40 | 1.6 | 3.2 | 4.8 | 6.4 | 8 | 9.6 | 11.2 | 12.8 | 14.4 | 16 |

| 50 | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

| 60 | 2.4 | 4.8 | 7.2 | 9.6 | 12 | 14.4 | 16.8 | 19.2 | 21.6 | 24 |

| 70 | 2.8 | 5.6 | 8.4 | 11.2 | 14 | 16.8 | 19.6 | 22.4 | 25.2 | 28 |

| 80 | 3.2 | 6.4 | 9.6 | 12.8 | 16 | 19.2 | 22.4 | 25.6 | 28.8 | 32 |

| 90 | 3.3 | 7.2 | 10.8 | 14.4 | 18 | 21.6 | 25.2 | 25.8 | 32.4 | 36 |

| 100 | 4 | 8 | 12 | 16 | 20 | 24 | 28 | 32 | 32 | 40 |

Example: So a 100 x 100cm hole (1 cubic metre) would need 40 bags of Marconite PREMIX to fill it completely. Assuming there are no other components in the hole absorbing some of the volume of the hole.

Marconite Product Specification

| Test | Min | Max | Unit | Test Status |

| Sieve +3.15 mm | 0 | 5 | % | Control |

| Sieve -0.25 mm (60 # BSS) | 0 | 10 | % | Control |

| Fixed carbon | 98.5 | 100 | % | Periodic control |

| Sulphur | 0 | 1.5 | % | Periodic control |

| Resistivity | 0 | 0.001 | Ohm.m | Control |

Test Results

Application

Marconite and Earthing of Towers

Towers used for power distribution, lighting and communication aerials are usually supported on foundations with each leg on an individual concrete base or all legs on a reinforced concrete slab. Earthing is traditionally completed with earth electrodes using conventional earth rods or tapes.

A. Marconite conductive concrete has a resistivity of 0.1 ohm metre.

B. Marconite can be placed as a blinding layer when excavating the foundations and connected by copper tape to the tower.

C. Bore holes are not required thereby reducing drilling and copper costs.

D. By incorporating a blinding layer with the foundation block the area available is considerable when compared to a single electrode, enabling the resistance required to be achieved.

Marconite and Earthing of Substations

Substations are earthed to contain any fault current within their boundaries. At the perimeter Bore Hole with Marconite is constructed all around i.e if 20Mtr Bore Hole is done – then next one will be done at 20 metre distance – this is done all around the perimeter. A 100mm dia bore hole with a 16mm copper rod encapsulated with Marconite has a large area of dissipation that will ground any fault current faster and more safely when compared to a 16mm diameter earth rod.

Some FAQ’s

Why is it good to use Marconite in order to reduce the soil resistivity and achieve results within the tolerable limit?

Marconite, when installed correctly, forms a concrete like product producing a permanent electrically conductive earth enhancement material with an electrical resistivity of 0.1 ohm.m. This is independently tested to IEC 62561-7:2018 standards. Using this kind of material is detailed with the international standard IEEE80 and how its use can affect the design of the earthing system.

What is the guaranteed life span of Marconite earthing compound?

If undisturbed, Marconite installations have been known to exceed 25 years of operation. Marconite are unable to offer a guarantee for the installation, only offer a certificate of conformity for the material itself.

What soil resistivity value should be considered for Marconite mixture for calculation purpose?

Marconite has a measured resistivity of 0.001 ohm.m. When mixed as per instructions the resulting concrete has an electrical resistivity of approximately 0.1 ohm.m as independently tested to IEC 62561-7:2018 standards.

When designing the earthing solution these figures can be used to estimate the overall effectiveness of the design. Exact figures can be established by manufacturing representative test blocks and having them independently tested.

How can Marconite sustain and dissipate the fault current to ground?

Marconite is an electrically conductive aggregate in its dry state and does not need water in order to pass an electrical current. When used to replace aggregates in a concrete mix the material formed is a dry solid electrically conductive concrete like material.

Its use within earth / grounding applications is well documented and its effectiveness to carry specific fault currents can be established though testing.

Is Marconite earthing compound CSA (Canadian Standard Association) certified?

No. Marconite is independently tested to the international standard IEC 62561-7:2018. If specific certification is required we suggest that the interested party is supplied sufficient Marconite to be tested in accordance with the exact specification that they require.

SUBSTATION EARTHING & MV HV CABLE JOINTING

To complement Earthing & Lightning Protection products.