Fujikura 90S+ | Splicing Tool | Fibre Core Alignment Fusion Splicer

Cable Splicing Tools

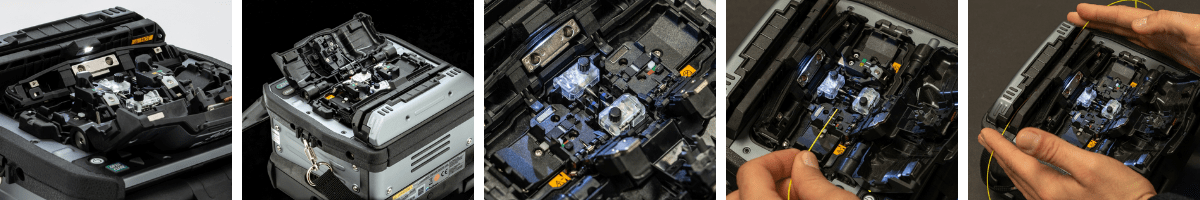

Fujikura 90S+

The Fujikura 90S+ is a single fibre core alignment fusion fibre optic cable splicing tool which sets a new standard in the market for fusion splicing.

The 90S+ is packed with many new and enhanced features specifically developed with the objective of enabling the user to work faster and with higher precision.

Overall splice processing time has been reduced significantly compared to the previous model, Fujikura 70S+.

Improvements include improved reaction time of automated wind protectors and automated heater, new fibre retention clamps, improved universal sheath clamps and a redesigned internal structure that matches the protection sleeve to the fusion splice point enables splicing to be achieved without the user needing to touch the Fujikura 90S+ once the cable splicing process has begun.

Fujikura 90S+ Core Alignment Fusion Splicer

Fibre Core Alignment Fusion Splicer

FUJIKURA 90S+ Features

- Active Fusion Control Technology (AFCT) – combining real-time fusion control with the cleave end-face analysis to determine the correct arc power to complete the splice.

- Market leading high precision and accurate core alignment technology with advanced image processing technology

- Improved automatic wind protector design which reduces overall splice time but can also be used in manual style

- High capacity lithium-ion battery (up to 300 splices)

- Patented easy splice protector positioning system

- Universal sheath clamps for standard 250 um fibre but also 900 um loose tube fibre types.

- Fibre Retention clamps

- Enabled with Fujikura’s unique “Active Blade Management Technology” with new capability to link up to 2 Fujikura CT50 cleavers simultaneously.

- A completely redesigned multi-function carry case and workstation

- Tool-less replaceable electrodes

- Touch screen

FUJIKURA 90S+ Specification

| Fibre Alignment Method | Active core alignment | |

| Fibre Count Can Be Spliced | Single fibre | |

| Applicable Fibre | Fibre Type | Single mode optical fibre |

| Multi mode optical fibre | ||

| Cladding dia. | 80 to 150μm | |

| Applicable Coating | Sheath clamp | Coating dia. : Max. 3000μm |

| Cleave length : 5 to 16mm *1 | ||

| Fibre Splice Performance | Splice loss *2 | ITU-T G.652 : Avg. 0.02dB |

| ITU-T G.651 : Avg. 0.01dB | ||

| ITU-T G.653 : Avg. 0.04dB | ||

| ITU-T G.654 : Avg. 0.04dB | ||

| ITU-T G.655 : Avg. 0.04dB | ||

| ITU-T G.657 : Avg. 0.02dB | ||

| Splice time *3 | SM FAST mode : Avg. 7 to 9sec. | |

| AUTO mode : Avg. 14 to 16sec. | ||

| Applicable Protection Sleeve | Sleeve type | Heat shrinkable sleeve |

| Sleeve length | Max. 66mm | |

| Sleeve dia. | Max. 6.0mm before shrinking | |

| Sleeve Heat Performance | Heat time *4 | 60mm slim mode : Avg. 9 to 10sec. |

| 60mm mode : Avg. 13 to 15sec | ||

| Fibre Tensile Test Force | Approx. 2.0N | |

| Electrode Life *5 | Approx. 5000 splices | |

| Physical Description | Width | Approx.170mm without projection |

| Depth | Approx.173mm without projection | |

| Height | Approx.150mm without projection | |

| Weight | Approx. 2.8kg including battery | |

| Environmental Condition | Temperature | Operate : -10 to 50 °C |

| Storage : -40 to 80 °C | ||

| Humidity | Operate : 0 to 95%RH non-condensing | |

| Storage : 0 to 95%RH non-condensing | ||

| Altitude | Max. 5000m | |

| AC Adaptor | Input | AC100 to 240V, 50/60Hz, Max. 1.5A |

| Battery Pack | Type | Rechargeable Lithium Ion |

| Output | Approx. DC14.4V, 6380mAh | |

| Capacity *6 | Approx. 300 splice and heat cycles | |

| Temperature | Recharge : 0 to 40 °C | |

| Storage : -20 to 30 °C | ||

| Battery life *7 | Approx. 500 recharge cycles | |

| Display | LCD Monitor | TFT 4.9 inches with touch screen |

| Magnification | 200 to 320x | |

| Illumination | V-grooves | LED lamp |

| Interface | PC | USB2.0 Mini B type |

| External LED lamp | USB2.0 A type Approx. DC5V, 500mA |

|

| Ribbon stripper | Mini DIN 6pin DC12V, Max. 1A |

|

| Wireless *8 | Bluetooth 4.1 LE | |

| Data Storage | Splice mode | 100 splice modes |

| Heat mode | 30 heat modes | |

| Splice result | 20,000 splices | |

| Splice image | 100 images | |

| Screw Hole For Tripod | 1/4-20UNC | |

| Other Features | Automatic functions | Splice mode selected using fibre type analysis |

| Fusion power calibration | ||

| Wind protector : open and close | ||

| Sheath clamp : open | ||

| Heater lid : open and close | ||

| Heater clamp : open and close | ||

| Reference guide | Video and PDF file stored in splicer | |

| Sheath clamp | Easy sleeve positioning clamp | |

| Electrode | Replaceable without tool | |

| Notes *1 Cleave length range depending on fibre type 5 to 16mm : 125μm cladding dia. and 250μm coating dia. 10 to 16mm : 125μm cladding dia. and 400 or 900μm coating dia. 5 to 10mm : 80μm cladding dia. and 160μm coating dia. 5 to 16mm : 150μm cladding dia. and 250μm coating dia. *2 Measured with a cut-back method relevant to ITU-T and IEC standard after splicing Fujikura identical fibres. The average splice loss changes depending on the environmental condition and fibre characteristics. *3 Measured at room temperature. The definition of splice time is from the fibre image appearing on LCD monitor to the estimated loss displayed. The average splice time changes depending on the environmental conditions, fibre type, and fibre characteristics. *4 Measured at room temperature with the AC adapter. The heat time is defined from the start beep sound to the finish beep sound. The average heat time changes depending on the environmental conditions, sleeve type and battery pack condition. *5 The electrode life changes depending on the environmental conditions, fibre type and splice modes. *6 Test condition (1) Splice and heat time : 1 minute cycle (2) Using the splicer power save settings (3) Using a not degraded battery (4) At room temperature The battery capacity changes when testing with different conditions from the above. *7 The battery capacity decreases to a half after approx. 500 discharge and recharge cycles, The battery life is shortened further when using outside of the storage temperature range, operating temperature range, if completely discharged by storing for a long time without recharging. *8 Bluetooth® mark and logos are the registered trademarks of Bluetooth SIG, Inc. |

||

Fibre Optic Cable Splicing, Jointing, Terminating & Stripping Tools

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV