Reducing RSI Caused by Cable Crimping Using Ratchet Type Tools

Published 02 Apr 2024

manual ratchet Crimping tools

Reducing RSI In Cable Crimping Applications

Many cable crimping applications throughout the industry are conducted using manual ratchet tools or hand hydraulic tools. Depending on the number of operations conducted each day and the hand force required to close the handles of the crimping tool, Repetitive Strain Injury (RSI) can result.

➡ Thorne & Derrick, are leading suppliers of cable crimp lugs and associated crimping tools for Low, Medium & High Voltage Cables and Power Systems.

The average force required to close the handles of a ratchet crimp tool is 22kg, and with many applications in factories and OEM’s requiring 250+ terminations per day, a significant risk is exposed.

Employee health – Less physical effort due to electrically-driven tools

CABLE CRIMPING & HEALTH & SAFETY

Looking to statistics available on-line, 29% of repetitive strain injuries will result in Carpal Tunnel Syndrome (CTS). This condition is where the Median nerve in the wrist is squashed in the Carpal tunnel, creating chronic pain, pins and needles, and numbness in the fingers and hand of the operator.

In worst cases CTS can only be resolved with surgery, one hand at a time, resulting in employees being unable to work for 6-8 weeks.

Those at risk of CTS are employees where they have a combination of:-

1. Repetitive bending and stretching of the hand

2. High force applications of squeezing or gripping cable cutting or crimping tools

3. Exposure to high vibration (e.g. motor driven saws/ grinders)

Electromechanical Cable Crimping Tools

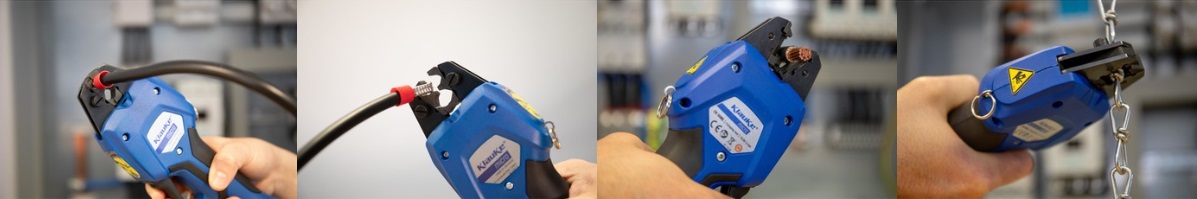

The new alternative to manual ratchet crimping tools for high volume, high force applications, is the Klauke Micro tool. This is an electro-mechanical tool suitable for Pre-insulated connectors (up to 16sqmm), Boot-lace ferrules (up to 50sqmm), and Cu tube lugs (up to 25sqmm). The Micro provides a 90% reduction in hand load experienced by the operator to help keep employees safe and maintain high productivity.

Electromechanical Crimping Tool Operation

Choosing the correct electromechanical crimping tools can help reduce workplace injuries and improve site and worker Health & Safety.

The Micro is less than 1kg, completes in excess of 300 crimps per charge in less than 1.5 secs per crimp. As an intelligent tool, it ensures full closure of the jaws on every crimp and comes with the ability to link to Klauke iPress software, where quality records can be downloaded and stored for improved traceability.

Klauke EK 50 ML 0.14sqmm – 50sqmm Electromechanical Crimping Tool

There are more reported cases of CTS in our industry and with better, safer, more productive tool solutions available today, each employer has a duty of care to provide the most suitable tools to their employees.

Electrical Connections, Lugs & Tools for Crimping, Cutting & Punching | LV MV HV Cables

Insulated Cable Cutters

The Klauke ES32SISML-WSH is a battery powered cable cutting tool with a maximum cutting range of 32mm suitable for use with copper and aluminium conductors up to 300sqmm. The Klauke ES32SISML insulated cable cutter has a slim cutting head for Jointers working in substations, switchgear and trenches with confined spaces – this insulated tool provides advanced worker and electrical protection to utility contractors working live in the vicinity of energised Mains and Service cables up to 1000V.

The insulated tool is typically used by UK DNO’s and their ICP Contractors to core cut 185sqmm, 240sqmm and 300sqmm BS7870 Waveform 600/1000V cables.

Klauke cutting tools are available with 10.8V DeWalt Li-Ion Batteries and are fully insulated to the electrical requirements of IEC 60900.

Cable Innovation Tools & Accessories for Low & High Voltage Power Systems

THORNE & DERRICK are Specialist Distributors of LV HV Cable Jointing, Earthing, Substation & Electrical Eqpt up to 66kV – this includes the most extensive range of Ex Stock Innovation Tooling to facilitate safe and reliable preparation, termination and installation of cables.