- Ensuring Optimum Performance Of Cembre Crimping Tool – Model HT131-C

- Cembre Cutting Tools Instructions For Use – Model B-TC950

- Cembre B1350-CE v. B135-C Crimping Tools Performance Comparison

- Replacing Cembre Cable Cutting Tool Blades – Model HT-TC051

- Maintenance For Cembre Cable Cutting Tool – Model HT-TC051

Maintenance Of Flexible Hose In Cembre PO7000 Hydraulic Pump

Published 13 Jun 2018

Cembre PO7000 Hydraulic Foot Pump

-

Uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Thorne & Derrick International are Main UK Stockists and Suppliers of Cembre tools including crimping and cutting types for all constructions of LV MV HV cable including medium/high voltage 11kV/33kV power cables.

The following short article provides useful instructions about how to correctly maintain the flexible hose in the Cembre hydraulic PO7000 hydraulic pump – supplied with 10 foot long high pressure flexible hose complete with an automatic, female, quick-coupler suitable for connection to a Cembre hydraulic crimping or cutting head.

The following excerpts are taken from the Operating Manual of Cembre PO700.

Cembre PO700 is a foot operated double speed hydraulic pump developing a maximum pressure of 10,000 psi for installing cable crimps, lugs and connectors.

Maintenance Of Flexible Hose

Cembre PO7000 Pump stored in plastic case VAL-P21.

The flexible hose is designed for high-pressure operation and should not be tightly bent, knotted, kinked or squashed.

♦ Warning: Take care when storing the pump in the plastic case, the hose should be coiled in wide loops.

High pressure flexible hoses are subject to a natural ageing process which can result in a reduction in performance potentially affecting safety of the operator and functionality of the hydraulic pump. In order to ensure safe use of the PO7000, Cembre recommends replacing the hose within 10 years from the date printed on the tool fittings. Pumps in the PO7000 range are supplied with a standard or non-conductive hose.

♦ Warning: Before using the pump always check the integrity of the flexible hose and the quick couplers making sure there are no abrasions, cuts, deformations or swellings.

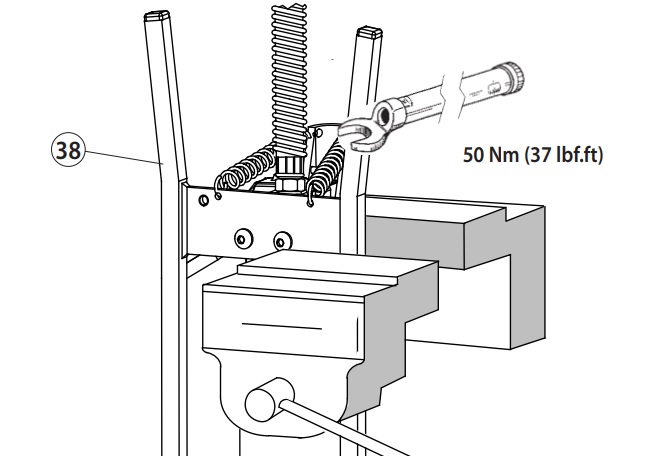

Fig 8 Hydraulic Pump Position For Replacement Of High Pressure Hose

Replacement Of The Pressure Hose

- Hold the pump base (38) in a vice, keeping the hose above the level of the vice

- Using a 19 mm fl at spanner, unscrew the hose from the pump body, while holding the coiled hose

- Carefully clean the thread of the pump body to remove any residual sealing materials

- Restore the gasket (tefl on tape) on the (male) thread of the new hose

- Connect the new hose, tightening the relevant nut to the correct torque ratio: 50 Nm (37 lbf.ft)

- Eliminate air in the hose as follows: unlock the pedal from the latch

- Depress the ball of the female quick coupler fitted to the end of the hose and pump slowly several times, until the oil flows

- Check the oil level and top up as described in operating manual

Cutting & Crimping Tools

Cable Crimping & Cutting Tools

This post is from a series of articles written to provide advice and guidance on the care and servicing of Cembre cable cutting and crimping tools.

Thorne & Derrick

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV | Cold Shrink

Further Reading

-

Operating Manual & Instruction Guide For Cembre Cable Crimping Tools – Model Cembre PO7000

Size: 1.27 MB

Operating Manual & Instruction Guide For Cembre Cable Crimping Tools – Model Cembre PO7000

Size: 1.27 MB